Woodworking Power Tools

When it comes to making cuts, driving screws and hammering nails, manpower can only get you so far. Using power tools drastically decreases your workload and increases your level of precision. You can also use power tools to do things that aren’t possible with hand tools alone, like routing and milling. It can be challenging to find the right tool that will last you for years to come, so our experts put together lists covering every kind of power tool on the market.

Updated July 31, 2024

Explore the differences between belt sanders and orbital sanders. Learn variations and how to use them effectively for woodworking and DIY projects.

Updated July 31, 2024

Learn step-by-step instructions to master three popular drywall finishes yourself. Add a professional touch to your walls and make your space unique.

Updated July 31, 2024

Do you want to build your very own cornhole boards? Learn how to make this backyard staple from scratch with our simple step-by-step guide.

Updated July 31, 2024

Learn how to expertly cut and install crown molding with these five essential tips from the pros.

Updated July 31, 2024

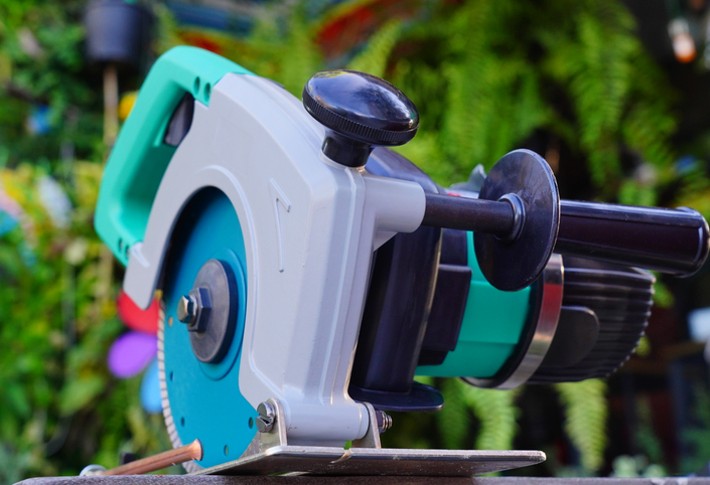

Do you have a big project in mind? Discover the best cordless circular saws for your next DIY project with the help of this buying guide!

Updated July 28, 2024

Looking for a portable sander that you can easily carry with you? We have highlighted and reviewed the best palm sanders of 2024 for you.

Updated July 21, 2024

Want to be a pro in whatever you do? We’ve listed some essential and underrated tools to hone your skills and be a master.

Updated July 21, 2024

Learn how to protect your wooden structures from dangerous wood rot, as well as how to detect, repair, and replace them if they are damaged.

Updated July 21, 2024

These cordless drills of 2024 will help you conquer any household project with ease, whether that's hanging a picture or putting together furniture.

Updated July 21, 2024

Review of the top-rated Dewalt Impact Driver – power, performance, and comfort all in one.

Updated July 21, 2024

Looking for an easy way to cut firewood and lumber? Check out the best small chainsaws of 2024 that'll help you get the job done.

Updated July 21, 2024

Learn how to cut metal like a pro using a circular saw with our comprehensive guide. Discover essential safety tips, blade selection, and techniques.

Updated July 21, 2024

New to circular saws? This beginner's guide teaches you how to safely and confidently use a circular saw for your DIY projects.

Updated July 21, 2024

Are you planning to tackle some woodworking projects soon? Discover the best types of circular saws and helpful tips with this comprehensive guide.

Updated July 21, 2024

Learn how to cut PVC pipe using three different ways. With tips for each method, you can confidently tackle any project that requires cutting PVC pipes.

Updated July 21, 2024

Are you confused about which saw to use for your projects? Learn the differences between table saw and miter saw and when to use each.

Updated July 21, 2024

If you have a lot of spare wood to dispose of or want to make your own wood chips, consider one of the top wood chippers of 2024.

Updated July 21, 2024

Learn how to cut firewood safely and efficiently with this straightforward step-by-step guide.

Updated July 21, 2024

Is it time to upgrade your old tools? Here are eight tools every DIYer should upgrade to cordless before tackling their next home improvement project.

Updated July 8, 2024

Here is our team’s review of the top sandblasters of 2024 for fuss-free rust removal that’s easy on the pockets.