Download the complete, step-by-step plans for the Table Saw Sleds from WoodsmithPlans.com!

A well-tuned saw with a sharp blade is a good starting point. But adding a crosscut sled can further simplify the process and aid in giving you predictable, high-quality cuts. While you may think of a sled as only helpful for cutting panels, there are some good reasons for using one for nearly any size workpiece.

The main benefit of using a sled is that the workpiece rests on the surface of the sled instead of sliding across the saw table. This means the piece won’t shift or catch during a cut, so your odds of getting a cleaner cut increase. Also, the base of the sled and the fence provide zero-clearance support to the bottom face and back edge of the workpiece, reducing the possibility of tearout.

Clearly, a sled makes a lot of sense. But what kind of sled should you build? I’d like to share two designs that meet most of my project-building needs, as shown in the drawings. Think of these sleds as “everyday sleds” designed for general crosscutting duties when building any project.

ONE-SIDED SLED. The first sled shown in the main photo above is made to work from one side of the saw blade. It’s like an extended miter gauge with a base. What’s nice about this sled is that it doesn’t weigh much. This means I’m more likely to actually use it. The sled works great for accurately cutting parts that are 24" or shorter. The base will fully support panels up to 12" wide.

TWO-SIDED SLED. The other sled design is larger, which allows for cutting longer workpieces, as shown in the photo above. The space between the front bridge and the fence allows you to crosscut 12"-wide panels, much like the one-sided sled. But the base of this sled straddles the blade. Extending the base to the opposite side of the blade supports the waste piece as it’s cut away. The result is it can’t fall and possibly cause a split or kick back at you. The two parts of the base are held together with hardwood bridges.

SLED UPGRADES. A basic crosscut sled makes getting precise, square cuts a sure thing. However, you can get even more out of the sled with a few accessories.

SIMPLE STOP BLOCK. The photo above shows a basic hardwood stop block that I routinely use. But this block has a few tricks up its sleeve. The lower corners of the block are chamfered. This creates a relief space for dust so it can’t build up between the workpiece and the stop and spoil the accuracy of the cut.

Less noticeable is a wide, shallow rabbet on the back. The lip formed by the rabbet registers the block on the top edge of the fence. It functions to keep the stop block square to the base.

A clamp-on block has a couple drawbacks. First, you need to get out a tape measure every time you set it up. And with the block clamped in place, you can’t make other cuts without removing it.

TRACK & STOP. The answer to these drawbacks is to turn to a commercial T-track system. One of my favorites is shown in the photo above. A track is mounted to the top of the fence. It’s designed to accept an adhesive-backed tape measure and a swing stop. You can flip the stop out of the way to make other cuts without losing your setting.

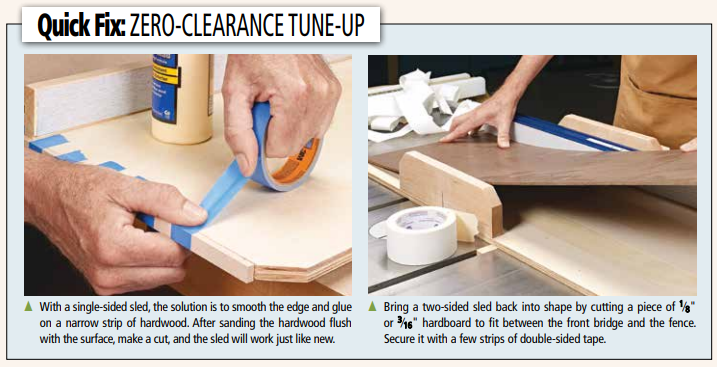

MAINTAINING A SLED. Over time, blade deflection and vibration may lead to the base of the sled getting a little chewed up to the point that it doesn’t provide the same level of support and backup that it used to. But don’t worry, you can quickly and easily refresh the sled and get tearout-free cuts without having to make a new one. The box above has all the details for each sled design.

A nice crosscut sled provides a higher level of accuracy and safety. More than that, it allows you to focus on the finer points of building projects and increasing your enjoyment of the process. That’s a win-win in my book.

You can find the complete step-by-step plans for building, setting up, and using these Table Saw Sleds at WoodsmithPlans.com. Download the Plans Here!