The Best Fence Clamps

- Milescraft Fence Clamp - Best Overall

- POWERTEC Universal Fence Clamp - Runner Up

- Rockler Universal Fence Clamp - Honorable Mention

Have you ever thought about what vernier calipers do out of the physics lab? They go straight to the workshops and make excellent assistants, holding pieces together. Yes! The assistants here are the fence clamps. These tightening and assembling pros are the handiest tool a carpenter, DIYer, mason, and anyone working with cutting and fixing tools can employ. The top-of-the-line fence clamps in 2024 will make sure that your mechanical projects are secured and materialized effortlessly.

However, one must be aware of the types and uses of different clamps, for fence clamps have a universe of their own. Read the article below to learn about our top 5 picks, along with a comprehensive buying guide. So, without further ado, we’re unleashing the fence clamps that bring precision to your handy tasks.

Compare The Best Fence Clamp In 2024

Milescraft Fence Clamp

– Best OverallThe Milescraft goods are pridefully running the game for woodworkers. These light weighed, strategically shaped clamps have an easy application and do not come in the way of the blade and the fence. The hook end of these fence clamps is fixed into the auxiliary fence by drilling a hole on its superior surface, and the clamp end is fastened on the fixed tablesaw fence with the help of a plastic knob. As the design implies, the clamp is snug and immovable if adequately tightened.

A thoughtful addition to the Milescraft’s fence clamps is it being clad in a rubber pad. This feature makes the clamp mar-free. Another advantage of this clamp is its wide range of expansion which allows it to work with fences of different widths. Moreover, the 4009 fence clamps are well adapted for both sacrificial and auxiliary fences.

- Clamp arm diameter is 3 and 8 inches

- Useable with all types of saws (router, table, miter)

- Ensure precision in the woodwork

- Stay out of the way of work

- Requires a square fence to hold wood pieces at 90 degrees

POWERTEC Universal Fence Clamp

– Runner UpThe aluminum-made Powertec fence clamps are compact, sturdy, and easy to handle. These clamps have installation the same as other fence clamps. This universal clamp has a wide range of separation between its clamps, the smallest distance being half an inch and the maximum up to five and three-quarter inches. This range of travel increases the clamp’s precision and workability altogether. It is a plus point that the Powertec fence clamps are compatible with all saw types and even the major fence types.

Alongside securing auxiliary fences, these universal fences are adjustable with sacrificial fences and allow easy rabbet joint formation. Moreover, the body of the clamp is light weighted and has no intrusion on the work side.

- Versatile usage possible

- Snug and durable

- Compatible to fence system 3/4” to 5-3/4” thick

- 2 universal fence clamps included

- Clamp might indent on the fence’s surface

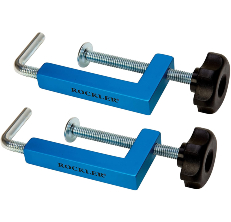

Rockler Universal Fence Clamp

– Honorable MentionThe Rockler’s universal fence clamps are the go-to choice for beginners and professional woodworkers alike. They are light-weighted and have perfect geometry for a clamp. These fence clamps are great holders and efficiently secure onto all sorts of surfaces saving manpower. In addition, the range of expansion of Rockler’s fence clamp is ideal for clamping on a variety of auxiliary fences.

Rockler’s are no standard fence clamps that works great for all types of grooving maneuvers, especially rabbeting. Furthermore, the diameter of the hook of the Rockler clamp is 3/8″ long, and that is quite an easy drill to make on any auxiliary fence.

- Compatible for all types of fence systems

- Suitable to work with different types of saws

- Range of travel from half-inch to five and quarter inches

- 2 clamps in one purchase

- Not enough screw pressure at the center of the auxiliary fence

Best Fence Clamps Buying Guide

Compatible with most table saws, fence clamps are tiny, yet they pack a stronghold and increase the workability for your wood jobs. They are appropriate for securing various types of auxiliary fences. In this buying guide, we are covering ground on the factors, features, and uses of the best fence clamps.

Check out the video from ‘Make Things’ for a cheap method to set up a sacrificial fence.

Types of Clamps

F clamps

Such clamps are the sturdiest fence clamps with a variety of uses. They are the top fence clamps to hold work pieces together, compress on structures, and cutting precision. The design of this type of fence clamp ensures maximum torque and clamping force on the fence.

Screw clamps

Screw clamps are just the clamps any woodworker needs! These clamps serve all the same purposes as an F clamp, and only they can be a little behind in strength. However, the advantage of the screw clamp is that its hook is drilled into the auxiliary fence and thus does not come in between the blade and the hands.

C-clamps

The C-shaped clamps or the carriage clamps are best used on curved structures where high yield pressure is required. There are different subtypes of the C-clamps based on slight variations in their functions.

Some C-clamps comes with fence clamps which are perfect for right angle squares corner clamp.

Wood screw clamp

Clamps with clunky wood screws are older variants with wooden jaws facing each other, tightened by spindles on either side. This particular clamp has a large jaw size with increased fence extension allowance and great claw pressure. Anyways, it is a limitation that jaws on either side hinder woodwork maneuvers.

Essential Consideration When Buying the Top Fence Clamps

Surface area of the clamp

The surface area of clamps has two basic impacts on the clamped structure: the indents they might leave, second, the pressure distribution. Therefore, it is essential to look for a clamp that has an anti-mar surface. Also, it is crucial to find a fence clamp that has coverage of a wider surface area. A wide clamp has a better spread of pressure through the clamped structure and better compression.

Weight of the body of clamp

The clamp of your choice should be lighter than the weight of the assembly itself. Heavier clamps have the disadvantage of falling over with the clamped structure or, worse, crushing them. On the other hand, lightweight fence clamps ensure that woodwork becomes easier for you.

Working mechanism of the clamp

Clamps of different shapes and different applications have contrasting mechanisms. The basic parameters of judging the right fence clamp for a project are to check the clamp’s sturdiness, clamp’s structure (you don’t want clamps coming in your way), the measure of its torque, weight of the fence braces, and most importantly their travel range.

Things To Remember When Using Clamps

Safety comes first

Clamps are employed in work including drilling, gluing, chiseling, and blade cuts. Therefore, it is highly recommended to have gloves and goggles on during work.

Basic clamp check

Before you start with your work, it is better to affirm if your fence clamp is the right type. Your last-minute checks should include clamp length, depth of reach, applied pressure of the clamp, and of course, the weight of the clamp. Also, check the length of the clamp arm if you have a specific woodworking project in mind.

Clamps have temporary use

It is of tantamount importance to understand that fence clamps are devices for temporary use. They are not permanent fixtures! Once the structure under work is in shape, the clamp needs to be taken off, and staples, screw fixtures, or gluing is recommended in its place.

Lubrication can take you a long way

Keeping the metallic parts of the clamp oiled is a good practice for woodworkers. It keeps the exposed surface of metallic clamps from rusting. However, it is equally important to keep the parts of the table saw fence clamp dirt-free, away from blade damage, and free of products like glue, solution, etc.

Uses of Various Fence Clamps

Carpentry

Router table fence clamps are a mandatory tool in woodwork. They hold wood pieces together while the corners are put together and the edge smoothened.

Lamination and gluing

Fence clamps are engineered to compress the structure in between and hold them upright. Thus they are pretty handy in the gluing process where even pressure is required on the setting structure.

Masonry

Brick clamps are a lifesaver for masons. Brick clamps make aligning the bricks in a row and at corners a lot easier.

Drilling

The primary function of fence clamps, “holding pieces together,” plays a vital role in the drilling process. Drilling is a work of precision that requires proper conditioning and complete focus. To meet the conditional requirement of the drilling process, fence clamps play the extra pair of hands you never had.

PEOPLE ALSO ASKED

There are various clamping methods based on the nature of the work. However, a few basic clamping methods include screwing clamp, squeezing clamp, hammering clamp, etc.

When using a fence clamp to glue pieces, it is better to have several clamps placed at an even distance on alternate sides. This keeps even pressure on the entire structure and ensures the proper setting of glue.

There are a handful of mistakes that novices are likely to make. The top of the list is hammering the spindle rather than swiftly screwing it to the maximum when tightening the clamp. Also, it is an unsafe practice to use clamps as permanent fixtures on furniture or any daily use object.

The Woodsmith Review Team’s product reviews and in-depth guides are here to help you choose the best tools and gear to build great-looking projects confidently. Woodsmith is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Large language models (like Artificial Intelligence) may have been used in the research and creation of the content.

Inquiries regarding specific articles or product testing should be sent to aimperiapt@gmail.com