A bookcase that I made recently has evenly spaced flutes on the face of each of the face frame stiles. A core box bit in a router is the quickest way to form these flutes. I considered using an edge guide attached to my router, but keeping consistent spacing between flutes would have been a real struggle. Not to mention the possibility of the edge guide losing contact with the stile and spoiling the cut. Instead, I built this simple fluting jig to take care of both those issues.

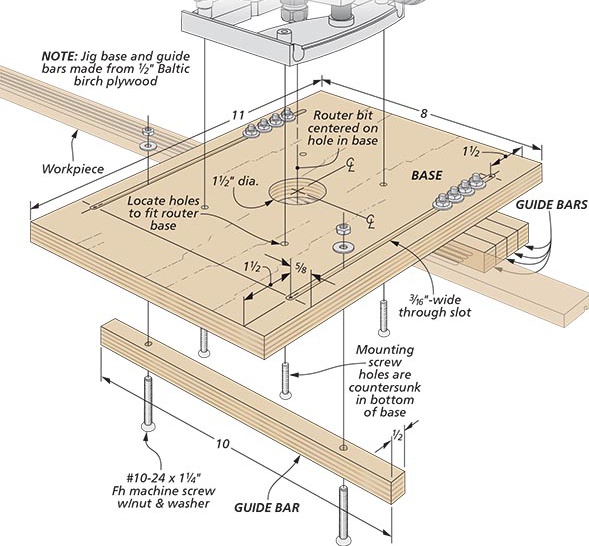

The construction of the jig is fairly simple. It consists of a base and five guide bars all cut from 1/2" Baltic birch plywood. Two slots along each side of the base allow the guide bars to slide along the bottom of the jig once the hardware is added. These slots are easy to make with a straight bit in the router table. If there’s one critical component to the fluting jig, it’s the guide bars. The width of the bars needs to be exactly the same as the center-to-center spacing of the flutes on your project — in this case, 1/2"-wide. After they’re cut to size, drill the through holes and countersink for the machine screws.

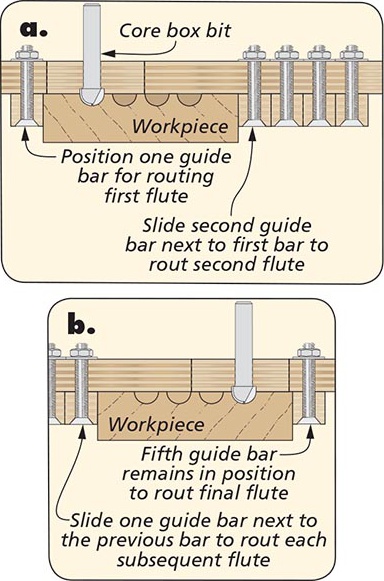

All that’s left is to drill the hole in the base for the bit to pass through and then mount your router to the base. I simply used the baseplate from my router to mark the mounting holes on the jig base. Details ‘a’ and ‘b’ show how to set up the jig.