When making toy parts, I often have the need to create a tenon on the end of a dowel. With the small size of most dowels, I had to come up with a safe solution. My answer is the simple device shown here.

When making toy parts, I often have the need to create a tenon on the end of a dowel. With the small size of most dowels, I had to come up with a safe solution. My answer is the simple device shown here.

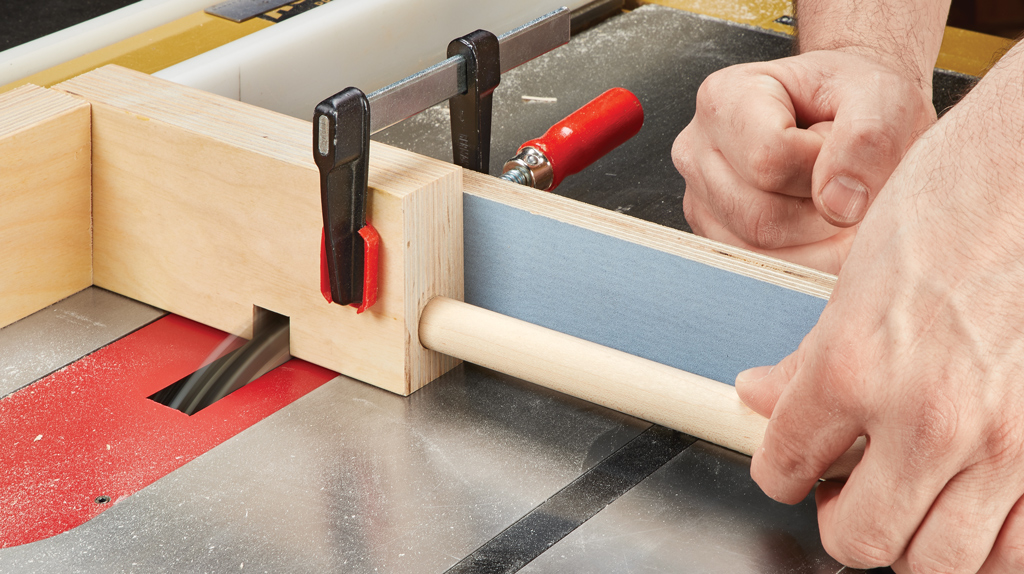

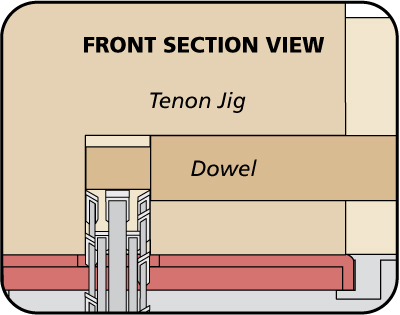

A Clever “JIg”. The jig is just a block made from two layers of plywood. It has a hole that is sized to fit the dowel, but still allows the dowel to be turned. A stop block is clamped onto the rip fence to position the jig over the blade.

Using the jig is simple. After transferring the hole depth to the face of the block, I can set my blade to cut the correct width of tenon. With the block clamped to my miter gauge, I insert the dowel into the hole and push it into the blade until the jig and dowel contact the stop. Then rotate the dowel to create the tenon.

The size of the tenon can be changed by adjusting the blade height.

The size of the tenon can be changed by adjusting the blade height.