Almost all of the case projects we design and build incorporate a face frame. This is a fairly standard design feature and it seems like a pretty basic concept. The face frame simply creates the drawer and door openings.

But in reality, when working out the details and fine-tuning a design, you find that there’s a lot more to it. Beyond providing a grid that frames and divides a cabinet, a face frame serves structural and functional, as well as aesthetic, purposes. So when designing, building, and installing a face frame, you need to consider several factors. Here I’ll offer an overview of the points you need to think about.

THE BASICS. A face frame is simply a framework made up of stiles (vertical pieces) and rails (horizontal pieces) that’s installed on the front of a case. The drawing below illustrates the most common configuration of the parts. The outer stiles usually run full height while the rails butt up to them. Any inner stiles that divide the frame butt up to the rails.

The face frame pieces are generally positioned over and attached to the sides and dividers of the case. But this isn’t always the rule. Sometimes the rails or internal stiles are “free floating,” attached only to other parts of the face frame. This allows you to subdivide the case into door and drawer openings without having to add internal case dividers.

STRENGTH. In most instances, a face frame serves several important structural purposes. When you build a case with an open front, you’re creating a weak point in its structure. Installing a face frame can help overcome this. It adds an extra measure of rigidity against the racking forces that can distort the shape of the case. This is especially true with large case pieces such as an armoire.

Face frame members also serve to reinforce the individual case parts — the sides and dividers. A stiff face frame stile glued to the long side of the cabinet will keep it from bowing and ensure that the openings stay consistent. Likewise, the face frame rails can help counteract any downward force exerted on the dividers. FUNCTIONAL BENEFITS. A face frame also offers benefits in very simple ways. For one, it provides a place to mount [hinges](https://www.woodsmith.com/review/door-hinge/) or catches for doors. And drawer guides or runners can also be mounted or hidden behind face frame parts.

Face frames can make building cases with plywood easier and more practical. The exposed edges of the plywood can simply be covered by the frame parts.

Sometimes structure, appearance, and function overlap in a face frame design. The lower right box shows a good example.

BETTER APPEARANCE. However, face frames are not installed for strictly utilitarian reasons. They can also be used to enhance the visual appeal of a cabinet.

Without a face frame, the front of a case can lack depth and “bulk.” And doors and drawers may lack the spacial separation needed for the best aesthetic effect. A well-proportioned face frame can make the difference.

A face frame is also a place to add detail. A simple bead molding along inside edges can set off the doors or drawers. Or a chamfer routed on the edge of the outer stiles can act as a visual transition at the corners of the case.

PART SIZE. One of the first details to consider when building a face frame is how to size the parts. Most of our face frames are cut from 3⁄4"-thick stock, however the width of the parts can vary quite a bit. This will affect both strength and appearance.

There is no firm standard for the width of face frame parts. The trick is to size the parts to meet your design considerations. My loose guideline would specify that stiles should be at least 1 1⁄2" wide and rails 1 1⁄4". Obviously, the width of the stiles and rails will affect both its structural and aesthetic effect.

Often, it’s necessary to vary the width of the rails on a particular case. The upper and lower rails can be made wider to accommodate moldings that will be added to the case (drawing above). But, it’s usually best to limit the width of the dividing rails in order preserve access to space within the case.

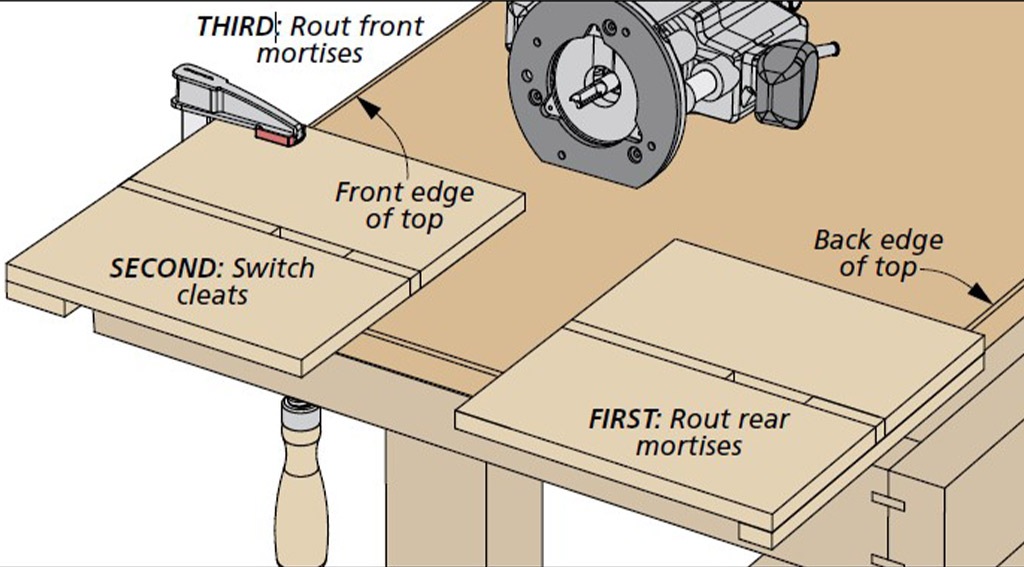

JOINERY. A face frame can be assembled in a number of different ways depending on what you need to achieve. Several of the joinery choices are shown above.

When maximum strength and racking resistance are the goals, the stiles and rails should be fastened together with a strong glue joint such as mortise and tenon or half-lap joinery.

A second tier of joinery options offers a tradeoff between strength and efficiency. Although not quite as rigid or long-lasting, pocket hole, dowel, or biscuit joints make up for this shortcoming by being fast and easy to create.

A small case may not need a rigid face frame. In this instance, I’ll simply install the parts with butt joints alone. However, all the frame parts will need to be securely attached to case parts.

Triple Duty

Wide side stiles (4" to 5") are commonly found on some traditional styles of furniture such as Shaker or Early American. This design feature simplified the construction while serving multiple purposes.

The wide stiles can be attached to both the case sides and the dividers — stiffening the case while eliminating the need for face frame rails. And as you see above, the bottom of the stile functions as a foot for the case. Finally, the wide stiles make a subtle and pleasing aesthetic statement.

installing a FACE FRAME

Before you can start building your face frame, you have a couple more decisions to make. Both are in regard to its final installation on the case. First, you need to know how the individual parts of the frame will be positioned in relation to the case parts. And the final question is the method you’re going to use to attach the frame to the case once it’s constructed.

POSITIONING THE PARTS. When it comes to the alignment of the face frame pieces on the case, you have a few options that offer different advantages. The frame is almost always designed so that the outer stiles end up flush with the outside edge of the case sides. But rather than try to hit this fit dead-on, I like to make the stiles a bit extra-wide and then trim them flush after installation (drawing below).

The drawings below illustrate the different ways a rail can be fit to a divider. The most common is to place the rail flush with upper surface. This will give you the clean look you may want for a door opening or the flat surface you need for a drawer or shelf.

The only catch is that this requires very accurate assembly and installation of the face frame. This finicky work can be avoided by setting the rails either above or below the edge of the divider. A rail sitting proud can create a useful lip that helps contain items in the case.

When doors are going to be added to an opening, you can place the rail about 1⁄4" below the top surface so the edge of the divider can act as a ready-made stop. If you do this, the divider will have to be solid wood or plywood with an applied edging.

ATTACHING THE FRAME. The last step is to attach the frame to the case. You have two goals here — to align it on the case properly and then to hold it there solidly and permanently. The drawings below show a few different examples.

One of the easiest ways to attach a face frame and my first choice is to simply glue it to the front of the case using lots of clamps. A tight glue joint between the face frame and either a solid wood or plywood case will form a very strong and permanent attachment. This basic method has proven itself over the years.

Mechanical fasteners such as nails or screws can take the place of the clamps during the glueup. The drawback to this assembly method is that you’ll have to fill the nail holes or plug screw holes.

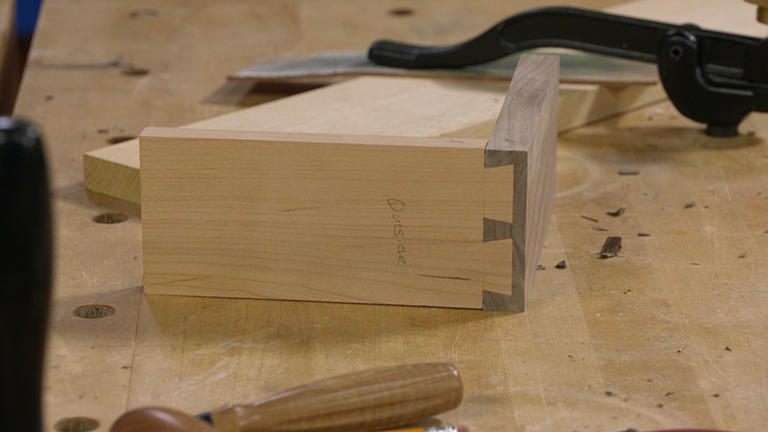

When you want to guarantee accurate alignment, you can add joinery between the face frame and case such as a rabbet or a tongue and groove joint. This will also add strength to the assembly, but on the downside, it adds another degree of difficulty to building and fitting the frame.

You can compromise and use biscuits or pocket screws to achieve the same end. But again, it’s debatable whether this extra work is worth the payback.

I guess that there are two basic lessons here. The first is that adding a face frame to a case makes good sense. Second, there a lot of ways to get the job done.