When it comes to cutting clean, accurate tenons, the table saw is the tool of choice. The bonus is there are two easy ways to do the job.

The mortise and tenon has to be near the top of the list for the title of “most useful woodworking joint.” Its combination of gluing surface and mechanical strength makes it ideal for many types of projects.

The mortise and tenon has to be near the top of the list for the title of “most useful woodworking joint.” Its combination of gluing surface and mechanical strength makes it ideal for many types of projects.

The upshot is that I use this joint often enough to have the routine down pretty well. I cut my mortises first, followed by the tenon. This means that cutting a tenon that fits snugly into the mortise is the “make it or break it” part of the job.

TWO TECHNIQUES.

But cutting accurate tenons doesn’t need to be a challenging trial. There are a couple of pretty foolproof ways to cut clean, snugfitting, perfectly centered tenons on the table saw.

The difference between the two techniques basically boils down to one thing — the type of saw blade used to do the job. One method uses a stack dado blade installed in the saw, while the other simply employs a standard blade.

Naturally, the question arises, which works the best and which should I use? Well, the standard blade method can give you smoother, cleaner cheeks, when that’s a necessity. While using a dado blade requires a simpler setup and can be quicker. Once you’re familiar with both techniques, you can choose the one that works best for you and the job at hand.

THE JARGON.

When talking about making tenons, it’s helpful to have all the names and descriptions straight. You’ll find that there are different types, sizes, and shapes of tenons, but a few common terms apply to all of them. A quick look at the drawing at left will familiarize you with the basics.

THREE GOALS.

When I cut tenons, I keep three goals in mind: First, the shoulders should be cleanly cut, perfectly straight, and square to the faces and edges. This creates a seamless fit to the mortised piece.

Second, the tenon needs to be accurately sized for a snug fit in its mortise. The correct thickness, width, and length all play a part in making a strong joint. Finally, the cheeks that provide the gluing strength need to be reasonably smooth. The good news is that either of these methods will fill the bill completely.

As mentioned, the technique for cutting tenons with a dado blade is a little simpler, so I’ll start with it. Then the following pages will cover the standard blade method.

Dado Blade Tenons

The advantage to using a dado blade to cut tenons is that the job goes quickly. A wide dado blade allows you to make the shoulder cuts and remove the waste from the cheeks in just a few passes. So this method is my first choice when I have a lot of tenons to cut.

THE SETUP.

|

| First Cut. Start with a cheek cut along the shoulder line. Concentrate on keeping the workpiece flat on the table and tight to the fence. |

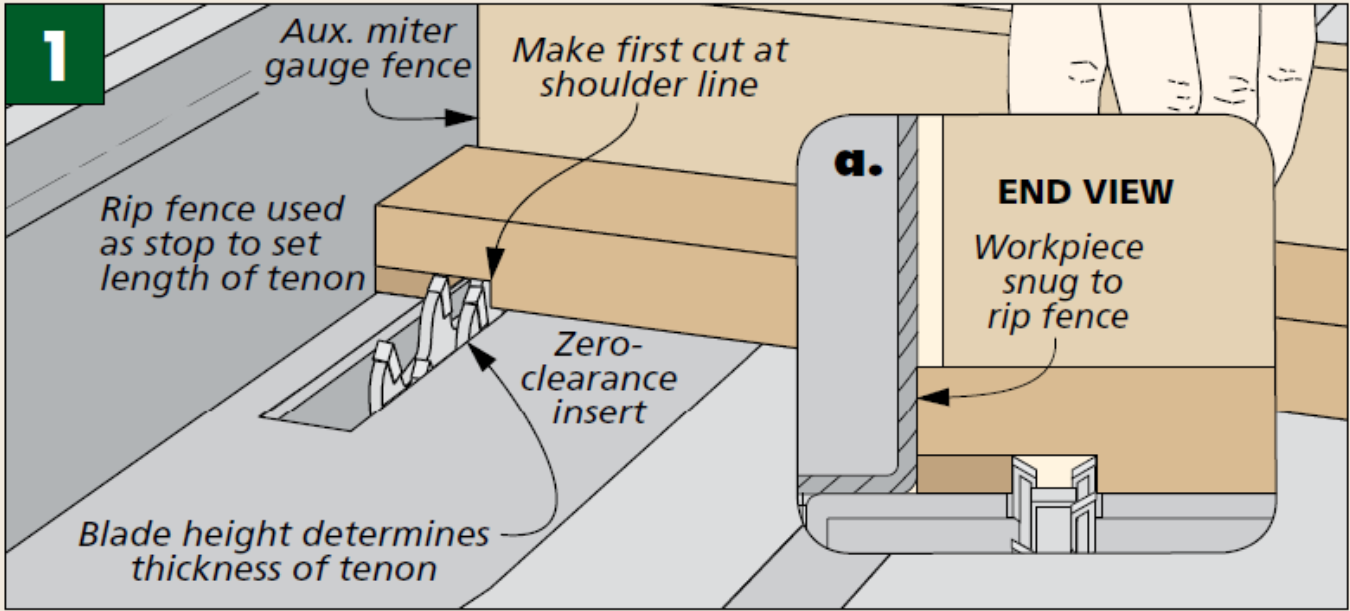

The table saw setup is pretty straightforward. A look at Figure 1 gives you the idea. A wide dado blade is installed in the saw along with a zero-clearance insert. An auxiliary fence is attached to the miter gauge to feed the workpiece and back up the cut. And the rip fence is used as a stop to gauge the length of the tenon.

ADJUSTMENTS.

With the basics in place on the saw, the cheeks and long shoulders are up first for attention. And the first step is to adjust the blade height. This sets the thickness of the tenon.

To do this, I use one of my workpieces as a test piece. Set the blade a little low, and then make a cut across the tip of the workpiece on each side. After comparing this “stub tenon” to the mortise, raise the blade and repeat the process until the corner of the test tenon will slide snugly into the mortise.

The same cut-and-test process is used to accurately position the rip fence. Start “short” and make a full cut just shy of the shoulder line. Then you can readjust the fence to sneak up on the layout line.

THE CHEEK CUTS.

|

| Nibble Waste. Once the shoulder cut is made, you can start to nibble away the waste working back toward the end of the tenon. Back and Forth. Clean up any ridges or scoring on the cheek by sliding it back and forth across the dado blade. |

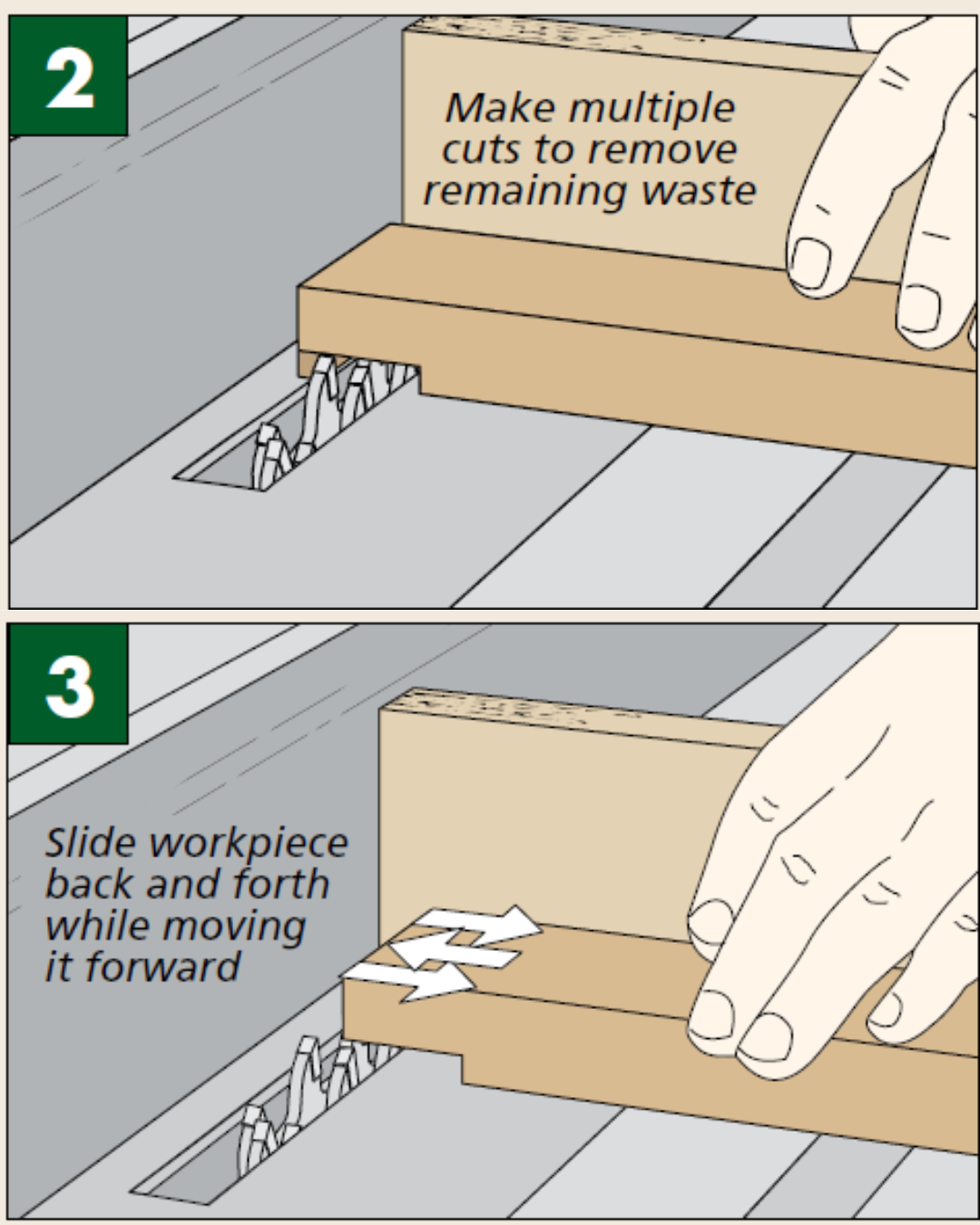

Now you’re through with the hard part. The cheek cuts will go quickly. Start with a cut at the shoulder line, as shown in Figure 1. Just concentrate on keeping the workpiece square to the blade, snug to the rip fence, and tight against the table. Then remove the remaining waste by working back toward the tenon’s end (Figure 2).

You’ll probably notice small ridges and score marks on the cheek left by the cuts. But there’s an easy way to clean these up — a series of side-to-side passes across the dado blade, as shown in Figure 3. Then flip the workpiece over, and do it all again on the opposite side.

SHORT SHOULDERS.

| Fiure 4: End First. To avoid chipout at the corners, the edges and short shoulders are cut starting at the end. Figure 5: Shoulder Last. Complete the tenon edge by making a careful cut along the short shoulder. |

At this point, you’ve established the length and thickness. Cutting the short shoul-ders and edges will bring your tenon to its final width. You may have to readjust the height of the blade, but the rip fence stays put. As you see in Figure 4, the workpiece is held on edge against the auxiliary miter gauge fence, but notice that the first cut is at the end of the tenon instead of the shoulder. This prevents splintering at the corner between the edge and cheek.

Now, nibble back toward the shoulder and finish up with a light cut (Figure 5). You want to avoid pushing too hard against the rip fence and possibly scoring or chipping the long shoulders. And after cutting the second short shoulder, the tenon is ready for its mortise.

Tenons with a Jig

When you need to cut a tenon with perfectly smooth cheeks (for example when making a bridle joint), the standard blade method is the answer. This technique separates the shoulder cuts and the cheek cuts into two operations.

When you need to cut a tenon with perfectly smooth cheeks (for example when making a bridle joint), the standard blade method is the answer. This technique separates the shoulder cuts and the cheek cuts into two operations.

First, the shoulders are cut with the workpiece flat on the saw table. Then, the workpiece is held upright in a tenoning jig to remove the waste from the cheeks (right photo). The jig makes control of the workpiece easier and results in more accurate cuts. I’ll talk a little more about the tenoning jig when it’s time to use it for the cheek cuts.

SHOULDERS FIRST

As I mentioned, the shoulder cuts come first. And there’s a good reason for doing things in this order. The length of the tenon is determined by the shoulder cuts, and this dimension can easily be measured as the saw is set up and the cuts are being made. But to accurately judge the correct thickness of the tenon, you need to compare it to the mortise. You can only do this after the waste has been removed with both the shoulder cuts and the following cheek cuts.

THE SHOULDER SETUP.

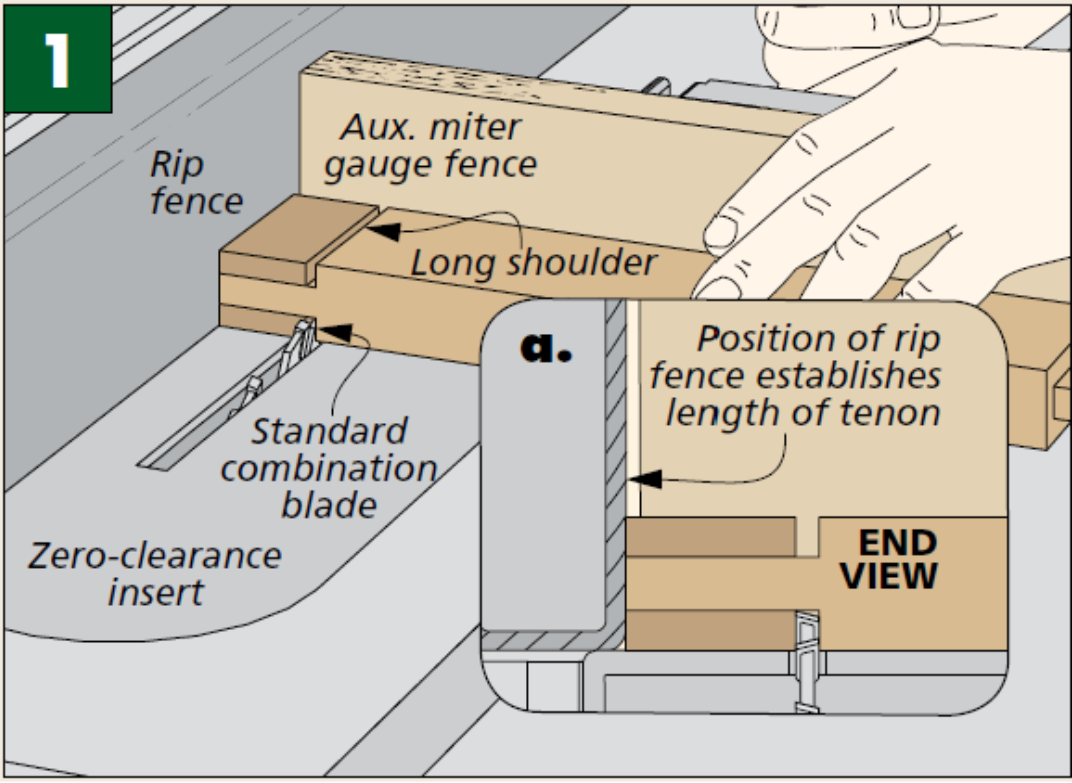

The table saw setup used to make the shoulder cuts (long shoulders first) mirrors the setup used for the dado blade method, as you can see in Figure 1. The miter gauge with auxiliary fence attached and rip fence serve the same purpose as before. The difference, of course, is that you’ll have a standard blade on the saw.(A combination blade works best.)

ADJUSTMENTS.

Again, both the height of the blade and the position of the rip fence need to be set. Here, the blade height isn’t quite as critical since the following cheek cuts determine the final thickness of the tenon. I simply sneak up on correct height with test cuts across the tip of the tenon.

Once the height of the blade is in the ballpark, you can zero in on the rip fence setting. This determines the length of the tenon, so here you want to be dead-on accurate.

THE CUTS.

|

| Figure 1: First, Long Shoulders. After adjusting the blade height and the position of the rip fence, a cut across each face establishes the long shoulders. |

When the adjustments are completed, it’s just one quick cut across each face (Figure 1). Keeping the workpiece snug and square to the fence and flat on the table is all you need to focus on.

SHORT SHOULDERS.

|

| Figure 2: Next, Short Shoulders. Stand the piece on edge to cut the two short shoulders. To do this, you may need to readjust the height of the blade. |

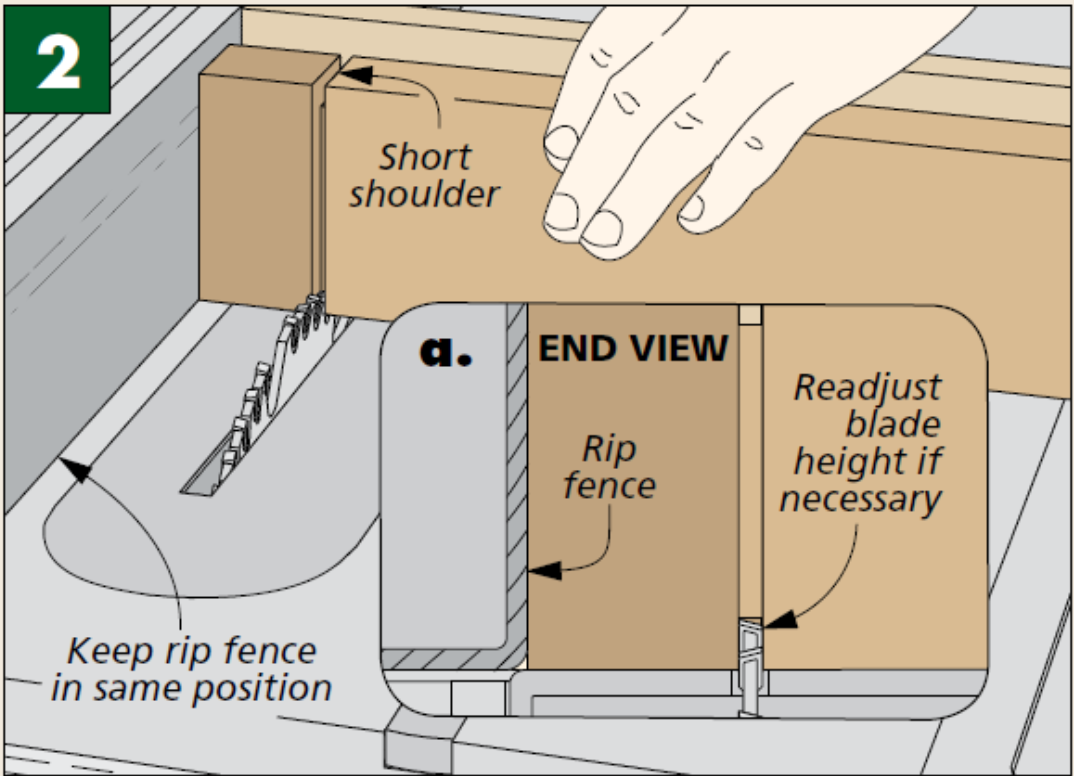

The short shoulders can be cut with the same setup and in the same manner (Figure 2). But you may have to change the blade height before standing the piece on edge for the single cut. Again the key is to avoid cutting into the clean, long shoulders. Just don’t force the workpiece too firmly against the fence, and this shouldn’t be a problem.

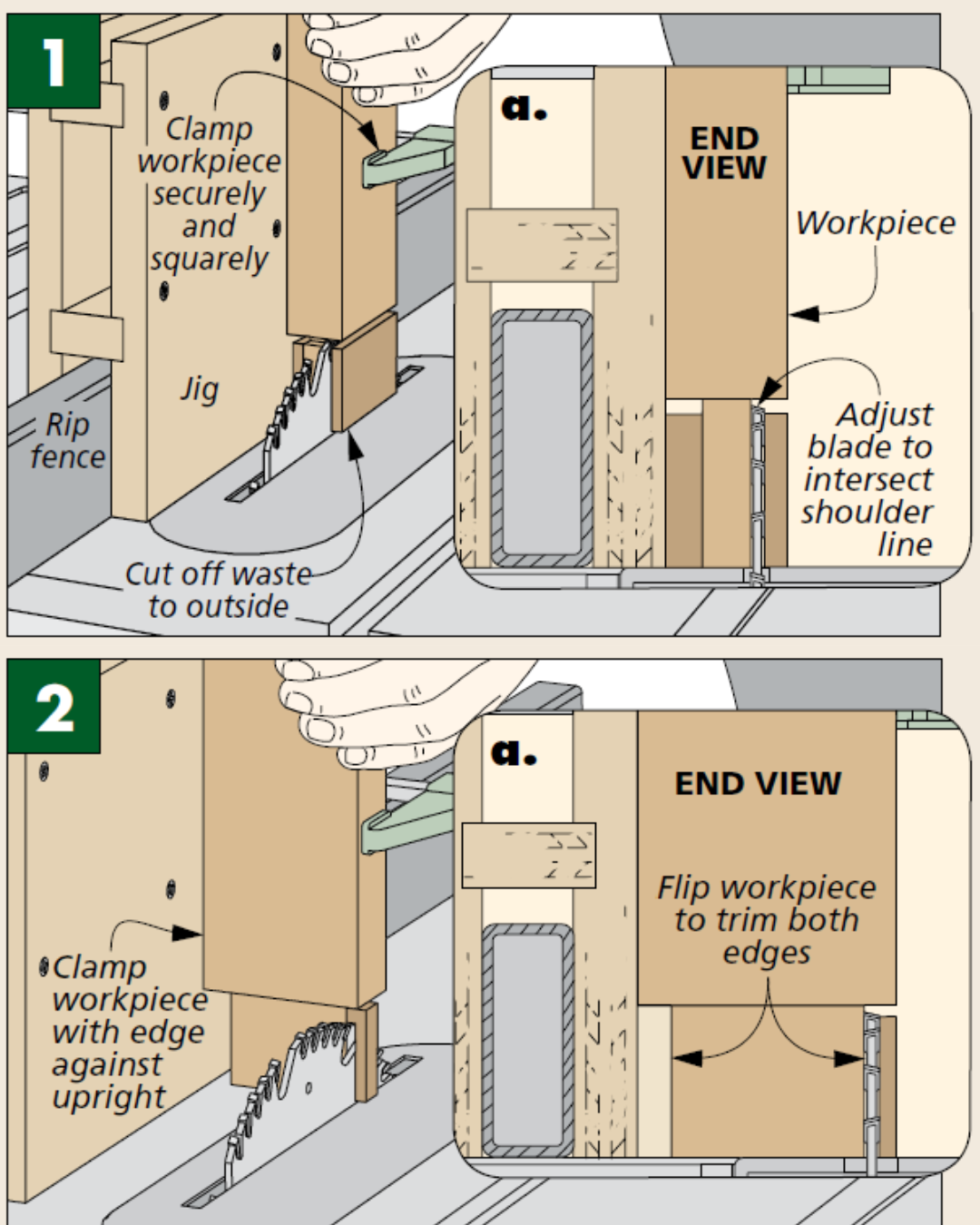

USING THE JIG

With the shoulders cut, you’re ready to put the tenoning jig to work cutting the cheeks and edges. There are many types of tenoning jigs, but the one I like to use, shown at right, has the dual advantage of being simple to build and easy to use. It’s essentially a saddle that rides along the rip fence of your saw to carry the workpiece past the blade. A vertical fence holds the piece straight and square. And any adjustment to the cut is as easy as moving the rip fence.

With the shoulders cut, you’re ready to put the tenoning jig to work cutting the cheeks and edges. There are many types of tenoning jigs, but the one I like to use, shown at right, has the dual advantage of being simple to build and easy to use. It’s essentially a saddle that rides along the rip fence of your saw to carry the workpiece past the blade. A vertical fence holds the piece straight and square. And any adjustment to the cut is as easy as moving the rip fence.

|

| Figure 1: Cheek Cuts. The workpiece is clamped securely in the jig. Make sure the waste falls to the outside. Figure 2: Trim To Width. Again, with the workpiece in the jig, trim the tenon to width with a cut across each edge. |

THE CHEEKS CUTS.

The cheek cuts come first, then the edge cuts. You start with a simple adjustment of the blade height. Just stand the workpiece beside the blade and let the shoulder cut act as your reference line while raising the blade. You want the blade to cut a hair below the shoulder line.

Next, you’ll position the rip fence. This will determine the thickness of the tenon, so getting this adjustment right is pretty important.

As you see in Figure 1, the fence is positioned so that the cut-off waste can fall free and not be trapped between the jig and blade. You’ll make one cheek cut and then flip the piece side-for-side in the jig to cut the opposite face.

To position the fence, I clamp a workpiece in place and start by setting it intentionally wide. Then I make a pair of cuts and compare the tenon to the mortise. This shows me how much to move the fence for another trial. I always like NOTE: All jig parts are #/4" plywood, fence is hardwood to take it slow and gradually sneak up on a good, snug fit.

When the fence setting is dead-on, you can cut all the cheeks — one side, then the other. The jig really does the work. All you have to do is make sure the workpiece is snug to the table and clamped securely. Then push it through the blade.

TOP AND BOTTOM EDGES.

The final step is to size the width of the tenon by cutting the top and bottom edges. This is also done with the piece clamped on end in the jig, but turned 90°, as in Figure 2.

Like the cheeks, the waste is cut away to the “outside” of the blade. But first, you’ll have to readjust the fence to size the tenon accurately. And here, you can simply test fit the width of the tenon directly to the mortise. Just a little firm pressure should seat the tenon. So you have two good choices. Either technique will give you great results. And when you need to go the extra mile, the box below offers a few tenon fine tuning tips.

How-To: Fine-Tuning the Fit

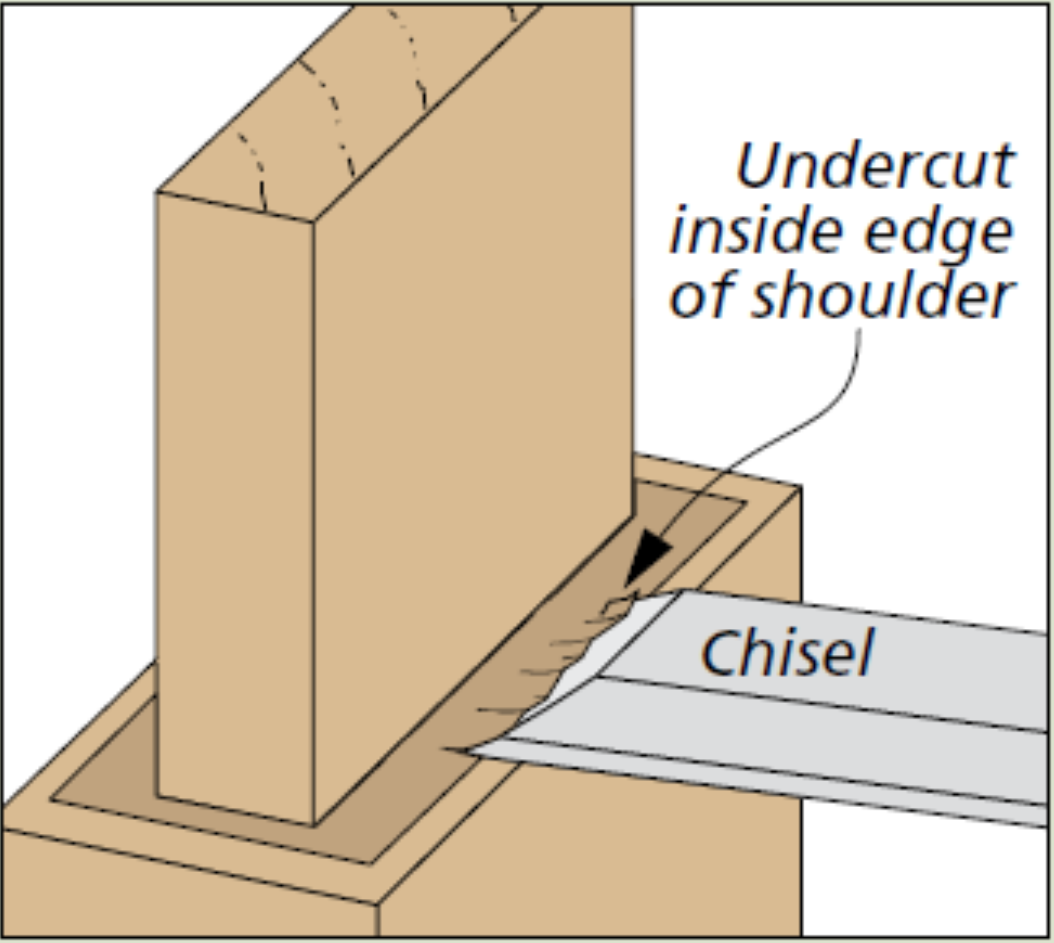

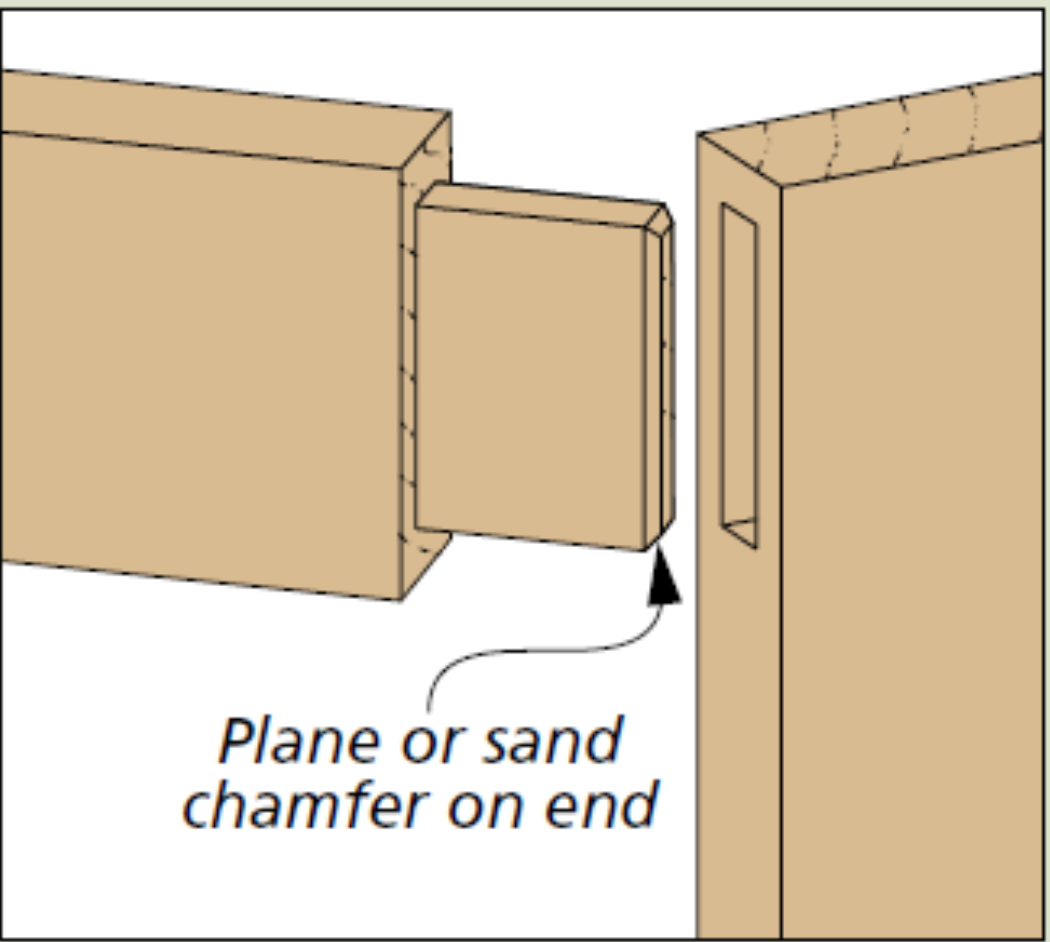

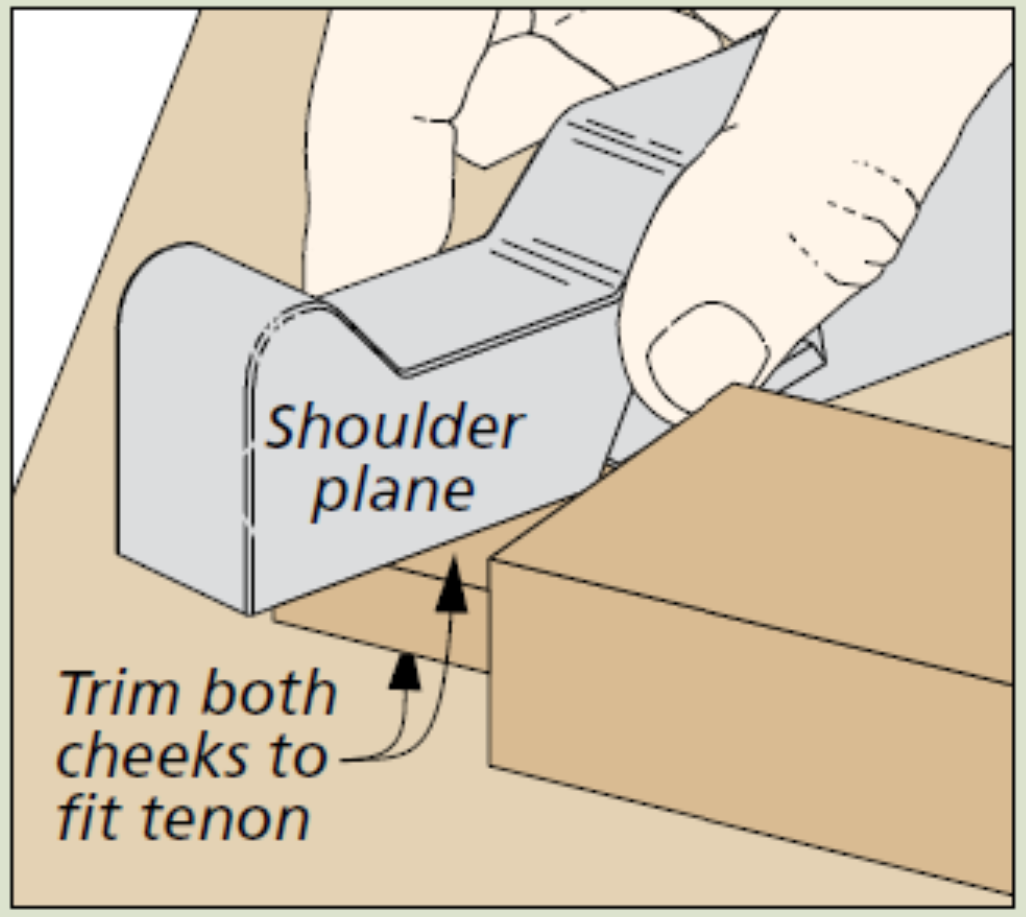

|

|

|

|

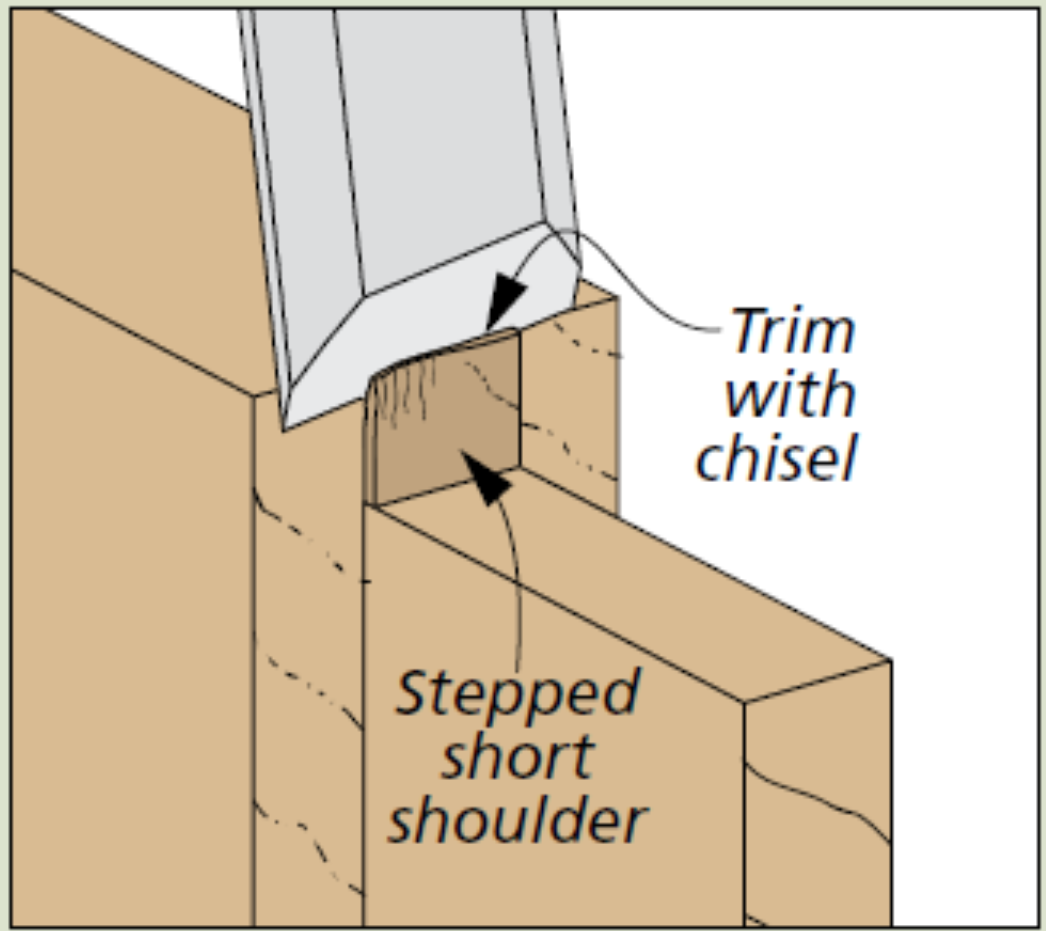

| Undercutting. To ensure a gap free fit, use a sharp chisel to undercut the shoulders. | Chamfered Ends. A short chamfer allows easier assembly and relief space for glue. | Too Tight. Correct an overly snug fit with a shoulder plane, a rasp, or sandpaper. | Trim the Shoulder. A stepped, short shoulder can be easily cured using a sharp chisel. |