There are a number of methods for cutting tenons, and the technique you ultimately choose is dependent on several factors. Everything from the number of tenons you have to make, to the size or complexity, to the smoothness you wish to achieve will impact your decision. To help you decide which tenon-making technique is right for you, let’s take a closer look at the options.

Some projects call for short, stub tenons with just two faces rather than four. In these instances, you may decide to forgo changing your table saw setup and simply cut the tenons with a standard saw blade.

Standard Blade

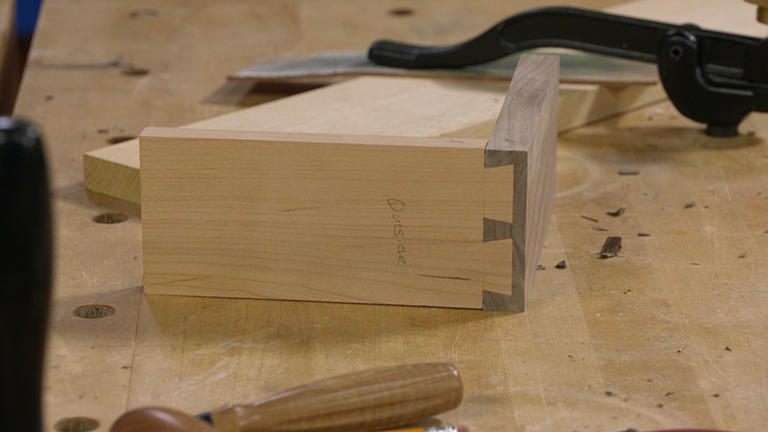

When making tenons this way, first position the rip fence as a guide for cutting the shoulders of the tenon. Then, after cutting the shoulders, you can slide the workpiece away from the rip fence for each subsequent cut to remove the waste from the cheeks of the tenon. It’s okay if there’s a little waste left between each cut, as shown above. That’s because once you’re done, you’ll use a sharp chisel to remove this waste and clean up the tenon.

Pros. If a tenon is short, this method is fast and doesn’t require devoting time to changing the saw blade setup.

__Cons. __ For larger tenons or multiple tenons, this is not the best method. It can be time-consuming and leaves a lot of cleanup work afterward.

Dado Blade

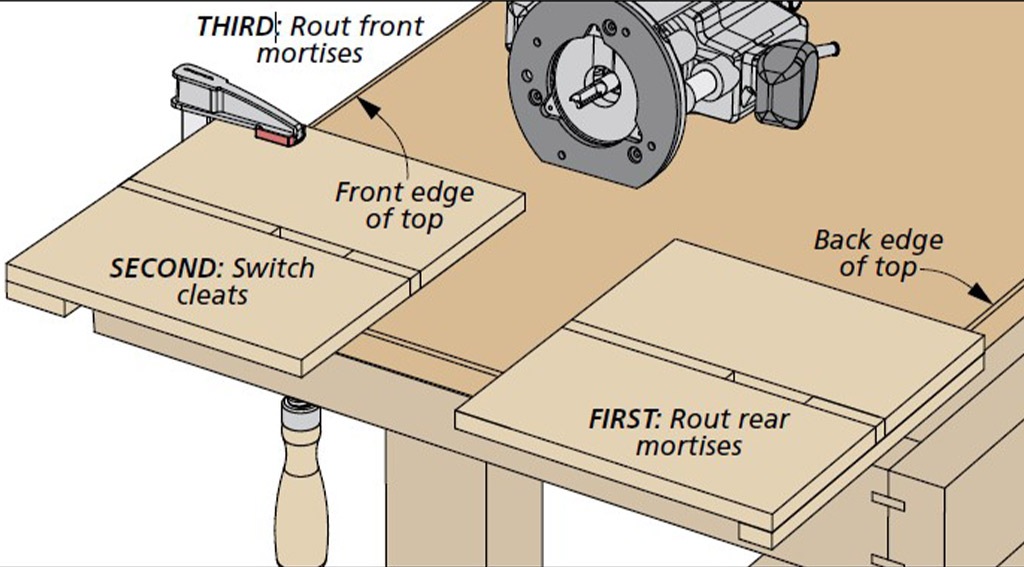

Many projects require tenons longer than the one shown in the previous slide. Any time your tenon is longer than half an inch or so, it’s probably worth your time to swap out your standard blade for a dado blade. Your dado blade setup may not be as wide as the tenon you’re planning to cut, but that’s okay. As with the previous technique, you can make the cut with a series of passes over the dado blade. Here again, you want to start by using the rip fence as a stop for establishing the shoulders of the tenon. Then, you can move the workpiece away from the fence with each following pass to shave the waste from the cheeks of the tenon.

Pros. This method makes quick work of larger tenons, and even if you have to cut each tenon cheek in multiple passes, it’s still faster than a standard saw blade. It also leaves cleaner cheeks than a standard saw blade.

Cons. One of the few drawbacks to this method is the time it takes to set up the dado blade and create an insert plate for it if you haven’t done so previously. The surface of the tenon may also be marked with ridges and imperfections, but these can be sanded away if needed.

Tenoning Jig

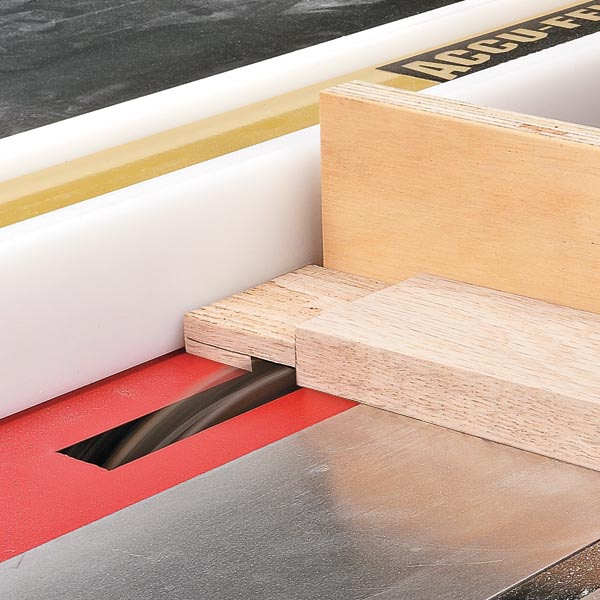

If you make a lot of projects that use mortise and tenon joinery, especially through-tenons where you see the end of the tenon, then it might be worth investing some money or time into buying or building a table saw tenoning jig. Once you get the jig set up and running, no method is better for making smooth-cheeked tenons quickly and accurately.

How You Do It. Of course, table saw tenoning jigs vary a bit based on the manufacturer. But they all hold the workpiece vertically so that you can cut each cheek with one pass through the saw blade. Tenoning jigs typically have a miter bar that runs in the saw’s miter gauge slot. And they feature several different adjustment points so you can fine-tune the settings to accommodate different sizes of workpieces or tenons. Before you use the jig, it’s a good idea to cut the shoulders of the tenons first. You can do this using a standard blade with the workpiece lying flat on the saw table. Then, after cutting the shoulders, make sure to set up the jig so the waste from the tenon falls to the outside and doesn’t get trapped between the blade and the jig.

Pros. A tenoning jig cuts tenons of almost any size easily. And you’ll be hard-pressed to get smoother results. Also, once you learn how to use the jig, setups are quick and easy. There’s also no need to change the blade to use a tenoning jig.

Cons. Really the only drawback to a tenoning jig is the cost, which is $100 or more for a good one.

You can build a tenoning jig like the one shown above, and that just requires a few hours of shop time and some common hardware. You can find step-by-step plans to make a shop-built Adjustable Tenoning Jig at WoodsmithPlans.com.

A tenoning jig (top photo) creates a smoother tenon than a dado blade (bottom).