When it came to building the Industrial Bookcase in issue 258, I found myself staring down quite a few mortises. If I’m going to be making that many mortises (or making sure that my bookcase is going to end up square), this is the jig I prefer. Honestly, if all I ever did with my plunge router was rout mortises, I would still consider it a great investment. It’s fast, easy, and most importantly, I get a clean cut with dead-on accurate mortises every time.

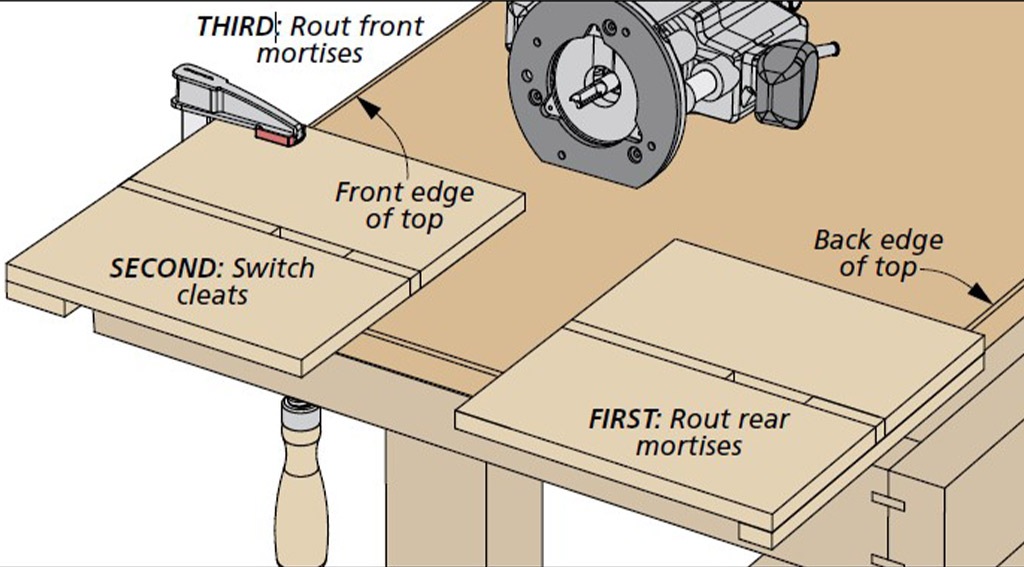

THE JIG. A good jig for the plunge router needs an easy way to guide it while making the cut. My solution is the jig you see here. To rout multiple mortises efficiently, it incorporates a pair of adjustable guides attached to a hardboard baseplate, which replaces the router’s baseplate. The guides on the jig snug up to either side of the workpiece to position and stabilize the cut. Then you can follow the guides with your router to cut a perfect mortise. Keeping the guides tightened down will make sure that each subsequent mortise on a piece will stay properly aligned.

THE SETUP. To get started, you’ll need the jig in place and a bit installed in the router. I prefer a spiral upcut bit when it comes to mortising. Once the mortise is laid out, clamp the workpiece down so that the jig can slide freely along it without obstruction.

ADJUST THE JIG. The next step is setting up the jig using the layout lines on the workpiece. To do this, set the plunge router and jig on the workpiece with the bit roughly over the layout, then slide the guides loosely up against it.

To center the bit on the layout, lower it to the surface and lock it in place. Now, you can “tweak” the position of the jig on the workpiece until the bit falls between the layout lines. Once you’re satisfied with the position of your router on the workpiece, snug the guides up to the piece and tighten them down. The jig should slide easily along the workpiece, without any slop or wobble, while also not catching on anything.

THE CUT. With the router in position over the mortise layout, you’re ready to start the cut. I use multiple passes with this jig to “step” the mortise down at about 1/4" per cut. I like to start the cut by plunging just to the inside of the end line. Then, I rout back to the layout line before routing forward. I find this to be much easier than trying to plunge multiple times in the exact same spot. When I reach the end line, I step my depth down and repeat the process.

To end the cut right on the mark, I like to clamp a stop block to the workpiece, which will bump into one of my guides once I reached the end line. Since the workpiece is trapped firmly between the two guides and the stop block will keep you from routing too far, all you need to concentrate on while cutting are the “plunge mechanics.”

While working on the long posts of Industrial Bookcase, I marked out all of my layout lines beforehand, then when it came time to rout I was able to leave my guides in place after the initial adjutment and simply work my way up the post, moving my clamped-on stop block along with me.

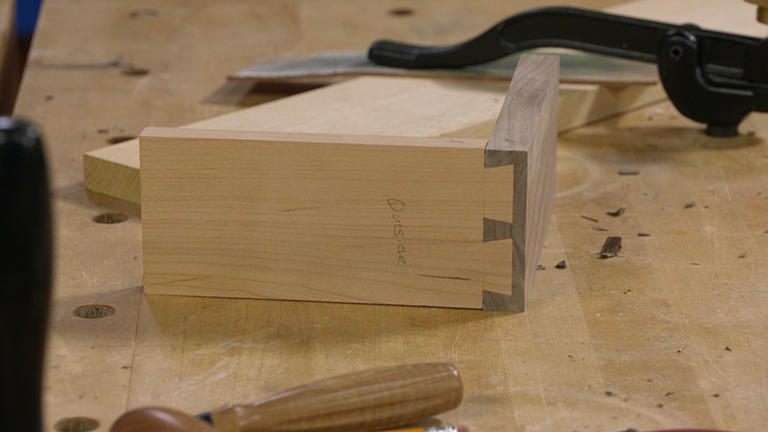

When you try this jig out for yourself, I think you’ll be pleasantly surprised that a technique this easy can give such top-notch results. All it took was a little cleaning up in the corners of the mortises with a chisel, and I had all 40 mortises made in the posts of my bookcase.