Ask a dozen woodworkers what's the "best" way to sharpen edge tools and you'll get a dozen different answers. But compared to the other options, diamond plates offer some advantages.

WHY DIAMONDS? First, diamonds sharpen steel faster than other abrasives. This is due to the hardness of the diamond crystal.

Another advantage is the ease of using diamond plates. You don't need to soak or prepare them in any way. You can use them dry or with a lubricant. There's also very little maintenance required. There's no need to worry about flattening a diamond plate like you would a waterstone or oilstone. The plates stay perfectly flat during normal use. In fact, they're ideal for flattening your other types of abrasive stones.

Finally, it's the only sharpening medium available to the home woodworker that's hard enough to sharpen carbide. This makes diamonds the go-to tool for touching up router bits (photo below).

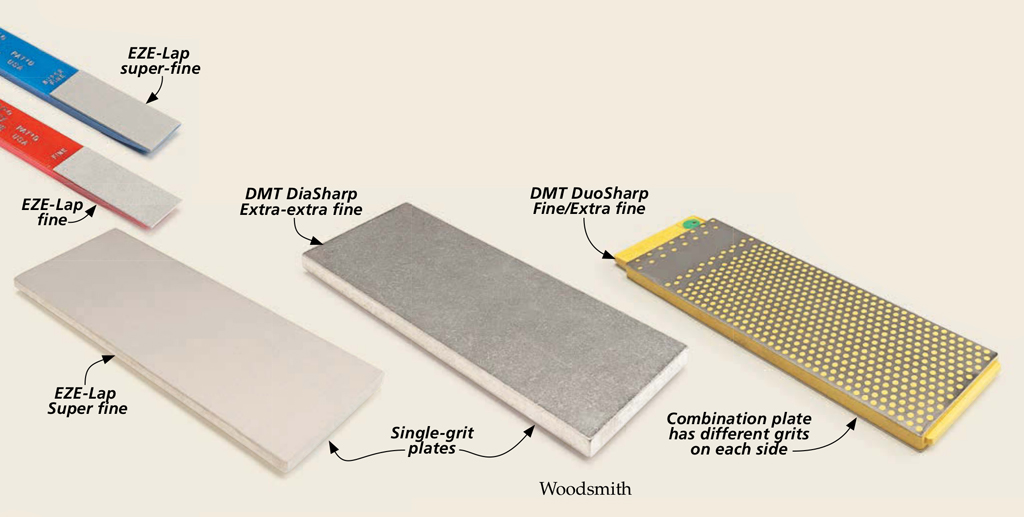

HOW THEY'RE MADE. Most waterstones and oilstones are solid blocks of abrasive. But diamond plates are made by bonding a thin layer of diamond particles to a steel plate. The two main manufacturers of diamond plates - DMT and EZE-Lap - each offer an assortment of plate sizes in a range of "grits."

TECHNIQUES. You can use your favorite sharpening jig on the diamond plates just like you would any other sharpening stone. The thing to remember is to keep the pressure light. Diamonds cut very aggressively, so a few minutes work on a stone is done in a few seconds on a diamond plate. You might want to blacken the edge of your tool with a marker before you start. This helps keep track of your progress as you sharpen.

DRY OR WET. You can use the plates dry, but I find the best results come by using water and a drop of dishwashing liquid to lubricate the plate. When you're done, simply clean off the plate with a brush and dry it with a paper towel. This is to prevent the metal particles from rusting.

One odd thing about diamond plates is that it takes a little use to break them in. Don't be surprised if a new plate leaves more scratches than you expect. After continued use, the sharpest points will wear down and the finish will gradually look more even.

WHAT'S NEW? Although diamond plates from DMT and EZE-Lap have been available for several years, until recently they've suffered from one shortcoming. You could only sharpen to the equivalent of 1200 grit with diamonds.

While that might be acceptable for some tools, if you're looking for a super-sharp edge for your chisels or plane irons, it's not quite enough. I always needed to finish by honing the bevel on a waterstone.

DMT's addition of an extra-extra fine plate makes it possible to assemble a complete diamond sharpening system. This 3-micron grit plate hones like an 8000-grit waterstone for a razor's edge. The box below helps compare this and other sharpening media.

CATCH THE WAVE. Sharpening carving gouges presents a special challenge. Another new product from DMT, known as the Wave offers a simple, but innovative solution. The Wave is simply a thin steel plate rolled to form both convex and concave surfaces. The diamonds in the surface allow you to find the right diameter for sharpening any gouge.

Once you give diamond sharpening a try, chances are you'll find a place for a few of these handy tools in your shop.

Grading the Grit: Apples & Oranges?

Comparing "grit" between different types of sharpening media can be difficult. Some comparisons are at best, approximations. And the designation of "coarse" and "fine" can mean completely different things in different systems.

Rather than rely solely on these labels, it's helpful to look at the size of the particles in each abrading medium, measured in microns (one millionth of a meter). This chart gives you a better idea of how the different sizes compare.