On a recent project, I needed a strip of molding to give a finished look to a panel made up of car siding strips. A table saw and a core box bit in your router table are all you need to make the molding.

You’ll start with a wide workpiece, create the profile on the edge, and rip it to size. Cut a shallow kerf to define one fillet of the molding profile. It’s best to use a rip blade for smooth, square edges.

The next fillet cuts are made with the workpiece on edge.

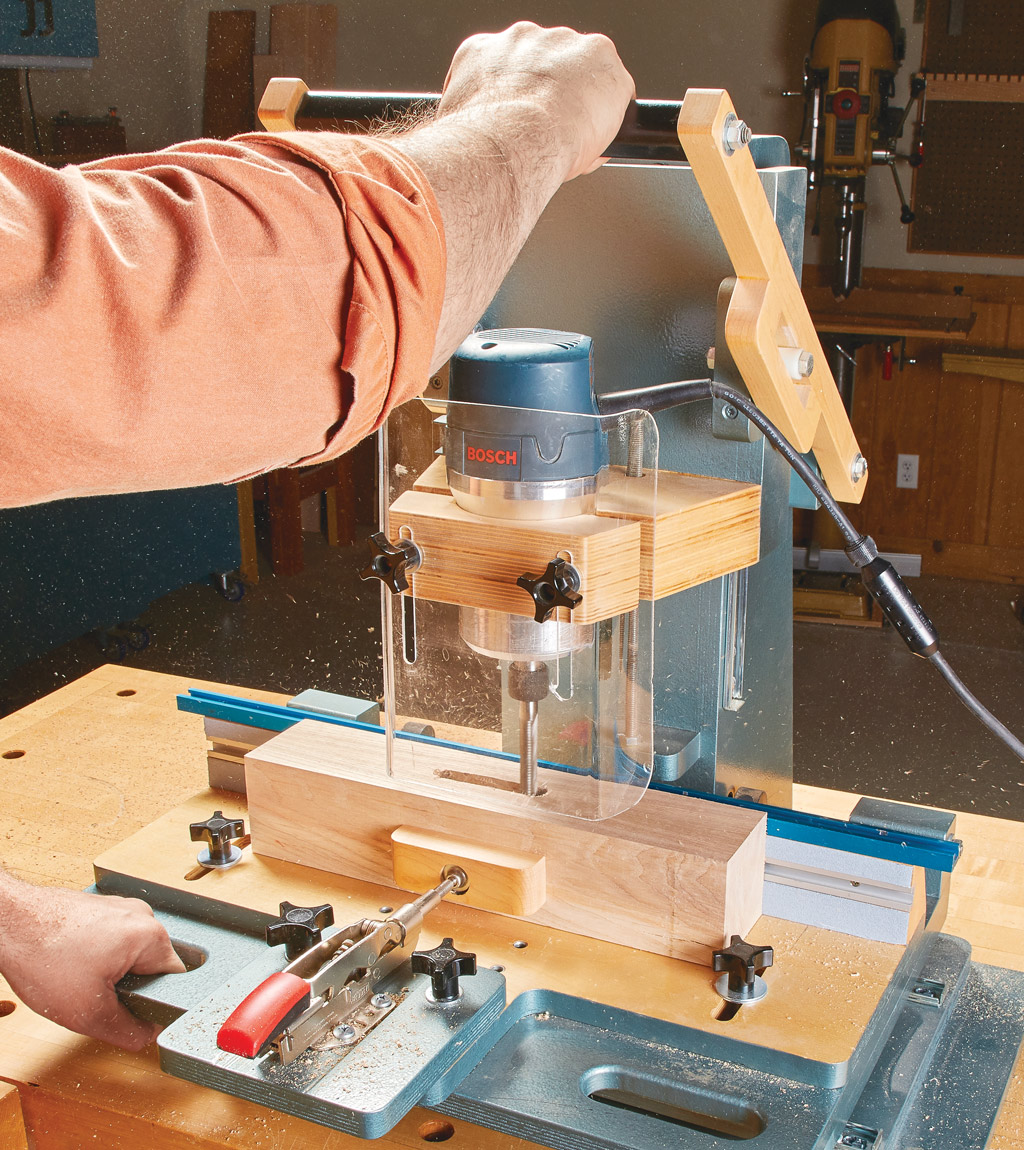

Rout the cove profile in several shallow passes at the router table. Raise the bit slightly between each pass.

Finally, rip the molding to final width at the table saw and sand it smooth.