Here are four simple accessories you can build to clear the air in your shop.

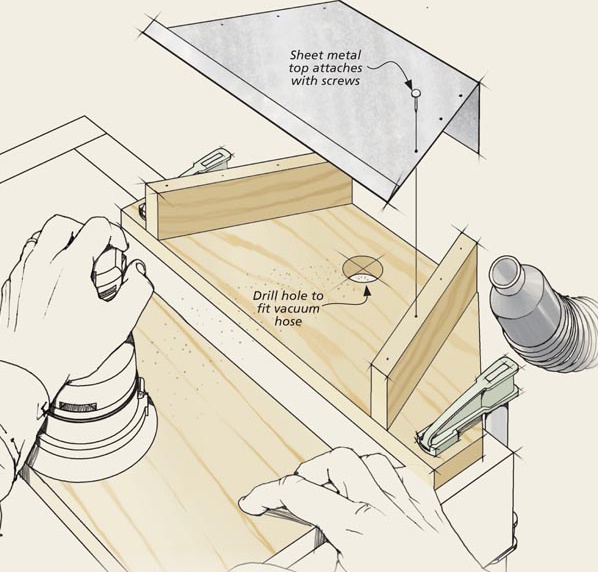

A random-orbit sander makes short work of tedious sanding chores. Unfortunately, it also creates a real dust problem. To capture this dust, I made the simple benchtop pickup shown here. The pickup works like a funnel. As you sand a workpiece, the dust is drawn into the mouth at the front and channeled to a vacuum hose by the two converging sides. You just hook it up and clamp it to the bench when sanding. You can size the collector to fit your bench or sanding table. The base should be big enough to hold the tapered pickup and still have room for clamping it to the bench. Drill a hole on the back of the base to fit your shop vacuum hose. You’ll need to miter the ends of the side pieces to fit flush on the front and back of the base. Then it’s just a matter of bending some light-gauge sheet metal to fit over the sides and connect to the base.

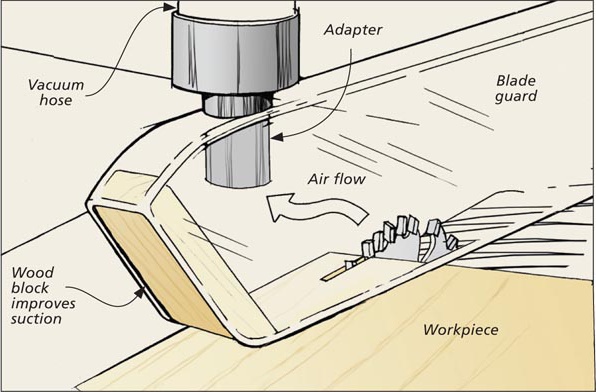

Nothing creates dust like a table saw. And even with a dust collector attached to the saw, there’s still a fair amount that ends up blowing back in your face. To collect this dust, I modified the blade guard to double as a dust collector by adding a vacuum hose adapter, as shown in the drawing at right. I also added a block to the front of the blade guard to improve suction. To keep the hose out of the way, just attach a hook to the ceiling. Now the dust goes into the vacuum instead of in the air. If you don't have a blade guard for your table saw, you can build one from scratch like this Dust-Free Blade Cover from WoodsmithPlans.com.

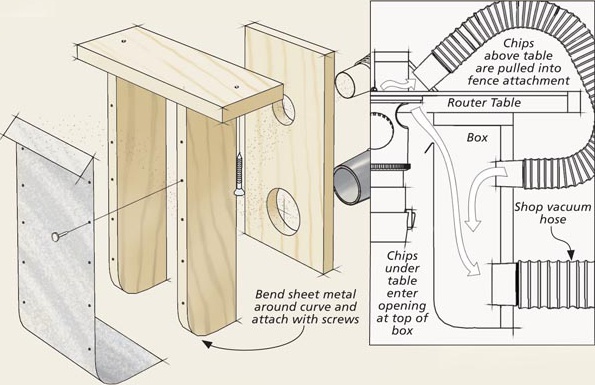

The router table produces dust and chips that collect both above and below the table. To pick up chips from both places with one dust collection hose, I built this box. You can easily adapt it to fit your router table. The idea is simple — the box has a narrow opening at the top to pull in chips from the router base. A hose going from the box to the fence gathers chips on the top side. I built the dust box out of plywood and sheet metal. Just cut the holes to fit your dust collector and you’re up and running.

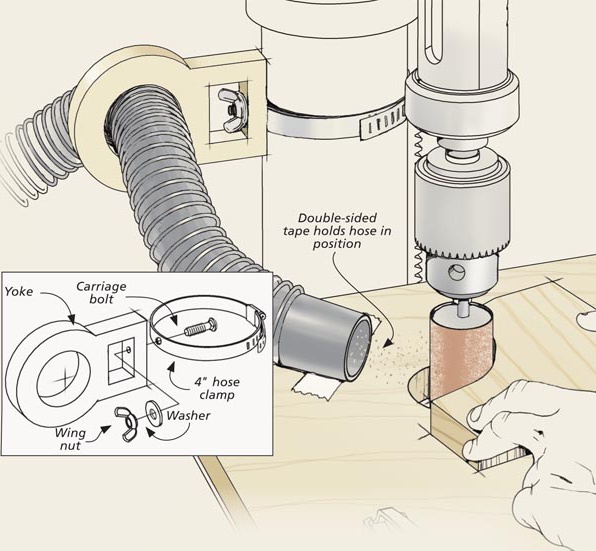

Sanding drum kits for the drill press are a great way to smooth curves and odd-shaped pieces. To collect the dust at the source, I slip the hose of my shop vacuum into the bracket shown here. The bracket is a keyhole-shaped yoke made from 3/4" plywood that holds the vacuum hose. A metal hose clamp secures the yoke to the column of the drill press. These parts are held together with a carriage bolt and wing nut. The bolt passes through a hole in the hose clamp into another hole in the end of the yoke. This allows you to tilt the yoke and adjust the position of the hose as required for nearly dust-free sanding.