Mortise and tenon joinery is my go-to joint for creating fine furniture and rock-solid shop projects like this Trestle Sawhorse. About the only downside to using this versatile joint is the time it takes to cut all the mortises for the project by hand. Well, for many projects, there’s an easier way to do this — the table saw. As you’re about to see, there are a few tricks to doing this quickly and easily. But don’t worry, you’ll still end up with a great-looking joint that will stand up to the test of time.

In the past, I’d drill and chop out the waste to create a through mortise. But there are a few downsides to doing that. It takes a lot of time. And keeping the sides of the mortise perfectly flat and square can be a challenge. Using a table saw solves all these problems. To create the mortise, you make the leg out of two separate pieces. Then, instead of making the mortise after the leg is glued up, you cut dadoes on the inside face of both halves of the leg first (detail ‘a’). This way, you end up with perfectly sized mortises once the two parts are glued together. And by carefully selecting the two parts of the leg, the joint line is almost invisible.

When I make a leg this way, I start by cutting two blanks to exact length and thickness, but I make them extra wide. This way, I can plane the legs down to finished width after they’re glued up. Once the blanks are sized, you can go ahead and cut the dadoes that will form the mortises. I use the rip fence as a stop as I work to ensure that each pair of dadoes lines up once the blanks are glued together. And be sure to make all the cuts at one rip fence setting before moving on.

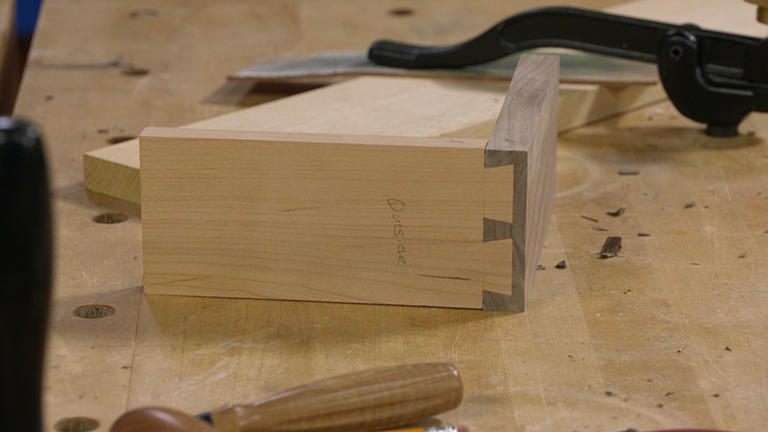

When it comes to gluing up the two halves of the leg, the trick is keeping the dadoes aligned as you clamp the pieces together. To do this, I use simple “keys.” All you need to do is cut some scrap blocks (I like to use MDF) to fit snugly in the mortises in the leg. Once the glue dries, all that’s left to do is plane each leg down to its final width. The end result is a perfect through mortise ready to accept a tenon.