Combining wood and glass in a project can result in something really special. Glass adds to both the function and the aesthetic appeal. For example, glass door panels and shelves can give a cabinet a lighter, more open feel while showing off the contents. And nothing beats the contemporary look and durability of a glass tabletop.

But just like wood, all glass is not the same. So when adding glass to a project, it’s important to match the type of glass you use to its function as well as the effect you’re trying to create. This simply involves knowing what the choices are and then following a few general guidelines.

THREE QUESTIONS. When choosing and ordering glass, there are essentially three choices you have to make. You need to decide what thickness to use, if the glass needs an edge treatment, and whether to order standard or tempered panels. The answers will depend on how the glass is used in a project. So let’s take a look at the options and see how they enter into your choice.

WHAT THICKNESS? You can purchase sheet glass in a variety of standard thicknesses — from 3 ⁄ 32 " up to 1" thick. Two of the commonly used thicknesses are referred to as single strength and double strength. Single-strength glass is the standard for windows and measures about 3 ⁄ 32 " thick. Double-strength glass is a slightly thicker ( 1 ⁄ 8 ") and consequently a bit stronger.

When installing glass in cabinet doors, it should be rigid enough to resist breaking, but also light in weight. Either single- or doublestrength is suitable, but I generally prefer the thicker type. As well as being stronger and less likely to break, double-strength glass is also stiffer. You’ll hear less “rattle” when a door is opened and closed. And a practical motive is that the 1 ⁄ 8 " thickness of double strength panels is easier to design and build around. The slight difference in cost weighed against the advantages makes this an easy decision.

For use in a picture frame, limiting weight can be a goal and strength and stiffness generally aren’t an issue. So here, singlestrength glass can be a good choice. You’ll also get less distortion from the thinner glass. But again, if you want to “standardize” your dimensions, choose double-strength.

GO THICKER. When a glass panel has to be self-supporting or support the weight of other objects such as with a shelf or a tabletop, thicker glass is usually necessary. Ordinary glass that’s 1 ⁄ 4 " thick or more is often referred to as plate glass. But other than increased strength, rigidity, and cost, it’s made no different than thinner glass.

For shelves that will bear a light to moderate load, 1 ⁄ 4 "-thick glass is the standard. If the load is heavier, books for example, you can up the thickness to 3 ⁄ 8 " or more. A thicker panel can also give a shelf a stronger visual presence.

Likewise, glass used for a tabletop should be thick enough to handle the load. If it’s supported in a frame, 1 ⁄ 4 " is my choice. When glass alone forms the top of the table, 3 ⁄ 8 " and upward might work better. The key here is that you want the thickness of a “stand-alone” glass top to be a good match to the size and proportion of the table.

AN EDGE PROFILE? Using thicker glass for a tabletop or shelves leads to the second topic. When a glass panel is permanently fixed in a frame, the sharp, possibly irregular edges are completely concealed. But when the edges of the glass panels are exposed both physically and visually, you’ll want to consider an edge profile, as shown in the photos at right.

This can be as simple as softening the sharp corners (called seaming) or having a more elaborate ground and polished profile added. Here you have a number of choices including flat, rounded (called a pencil edge), or chamfered.

Since the edges of the panels are mostly hidden, drop-in glass panels in a framed tabletop can simply be seamed. Likewise, you can often get by with this inexpensive treatment on glass shelving. When a tabletop has exposed edges or you’re ordering shelves for a more refined project, you’ll want to consider a ground and polished profile, as in the photo at left.

OR A BEVEL? Although not strictly an edge treatment, adding beveled glass to a project falls into this category. Here, a shallow bevel is ground into the surface at the edges of a thick glass panel — similar to a raised door panel.

As you see in the lower margin photo at right, the beveled edges add a subtle highlight to the glass door and case panels. A beveled edge is also an option for a glass tabletop. And if you want the glass in a project to make a bigger statement, check out the box below.

TEMPERED? The final concern relates to safety and durability. Glass can be tempered (heat treated) to give it two valuable characteristics. As a result of the tempering process, glass will break in a much “safer” way. Instead of creating sharp, jagged shards, tempered glass breaks into small, less harmful chips. An additional benefit is that a piece of tempered glass has four to five times the strength and impact resistance of standard glass.

There are a couple of instances in which I would recommend using tempered glass. I almost always use tempered glass for a tabletop. It’s much less likely to break and cause injury. Second, if you are installing glass panels in doors that are near floor level, make it tempered. Glass at this level is far more susceptible to being accidentally broken.

One downside to tempered glass is that it has to be special ordered from the factory by your supplier. And once glass is tempered, it can’t be recut or the edges profiled. So all the details need to be firmed up before you order.

The beveled glass in this china cabinet adds subtle depth and detail.

As you would expect, tempered glass is more expensive than ordinary glass, but not a great deal. So any time there’s a concern about safety, go with tempered.

The choices are really pretty straightforward compared to some of the other decisions you make when building a project. And that’s good. For me, the woodworking should be the focus and the glass a complementary accent.

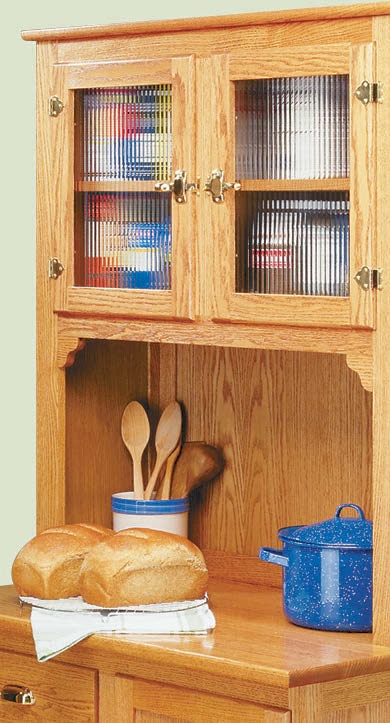

Patterned Glass

When incorporating glass into a project, you don’t have to limit yourself to flat, clear glass. Glass with a pattern or texture is available, or it can be frosted or colored. You’ll find that the choices are surprisingly varied. This type of glass can work well in a contemporary or even some traditional designs (right photo). When using textured or colored glass, all the same considerations discussed will apply.