A couple of months back, I sent a Facebook message in response to an ad for free hunks of cherry. I was in one of my "EVERY PIECE OF WOOD NEEDS TURNED INTO A BOWL" phases (which I go through occasionally), so I stopped and grabbed them. In our brief conversation, I learned the gentleman was an arborist in town. I mentioned how I had a sawmill on the way and was interested in picking up hardwood logs if he dropped any. He told me he would keep me in mind.

Fast forward a few months

Out of the blue, I get a call from Bojan saying they were taking down an ash tree if I could get there to cut it. Seeing how it was only 10 minutes from my house, I had the mill hooked up and on-site before the tree was on the ground. A rather un-eventful hour of milling saw the cutting up of a 10ft section of Ash trunk that was about 28" in diameter. In all of my never-ending excitement, I forgot to take pictures. Doh.

This past weekend, I get another call that another beautiful Ash would be on the ground in about an hour. So, I loaded my boys up in the truck (with plenty of snacks, juices, and a tablet each - I'm a great father figure) and headed up to Ankeny where the tree was being felled. I arrived with one of Bojan's crew still up in the tree, dropping limbs from the canopy. I'll tell you, a good tree crew and a good climber is a BLAST to watch. I got one quick video shot before I realized I should probably make sure everything's ready to go on the mill, so when the trunk hit the ground, I could get cutting. In the video below, it looks like the guy raking is close to where the branch swings. I assure you, it's just my camera angle.

After the limbing was done and the climber was on the ground, Bojan dropped the trunk in the yard and I got to work. If you've never stood in the vicinity of a large tree hitting the ground, I can't even begin to describe the thump when that trunk hits the ground.

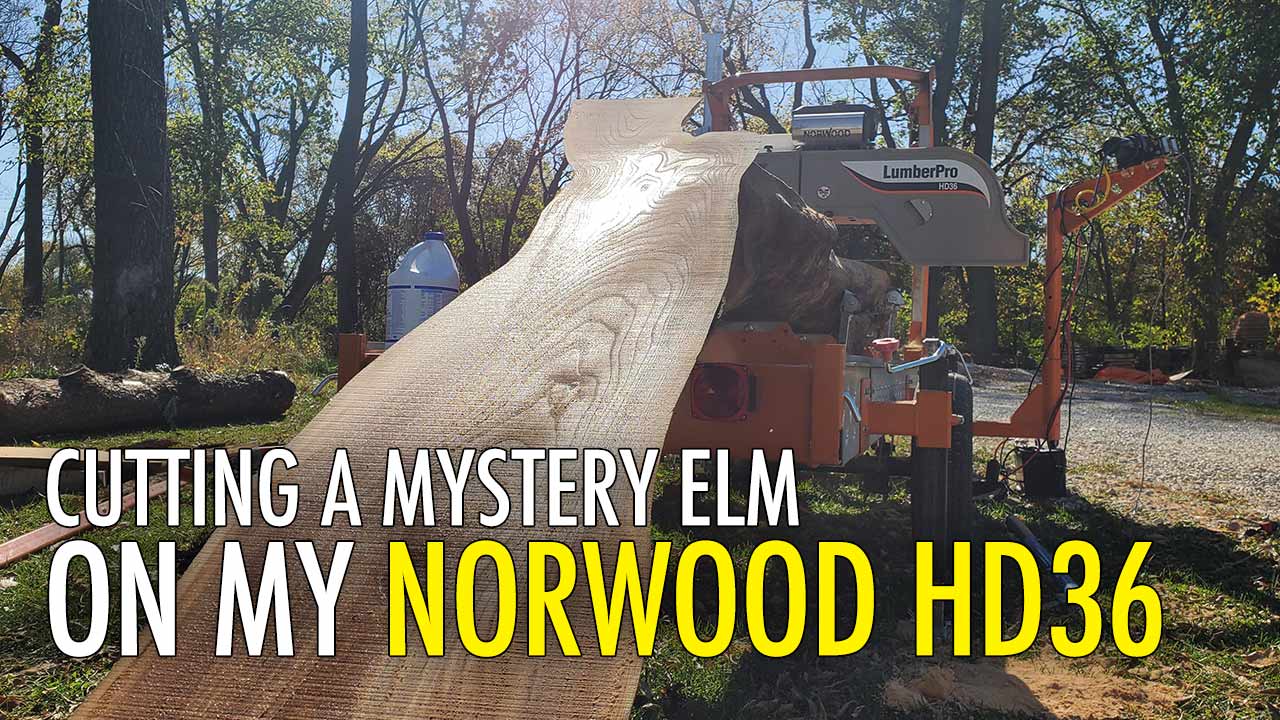

Ill tell you what - After watching me cut one tree a week before, the crew at CRO Outdoor Services was a ton of help getting the mill set up and ready to go. We got the mill positioned between the house and the log with the ramps in place. A few quick measurements showed that this log was approximately 32 inches in diameter (closer to 40 at the crotch), and 12ft long. That calculates out to about 4,000 pounds of pure, wet ash. The Norwood mill loaded it no sweat (not so for this chunky guy however - I need to invest in an electric winch for the mill!).

We stopped about 3/4 the way up the ramp, and I asked Bojan to trim the crotch slightly. The Norwood mill can handle up to 36"-diameter, but the crotch was going to cause the log to roll wildly when it finally made it to the bed.

Notice that Bojan is uphill from the log. When dealing with logs of ANY size, let alone logs heavier than most cars, you always want to be on the up-hill side and never in the line of one that might roll.

A few more cranks got the log up on the mill, and ready to cut. Again, here's where I wish I had a couple of pictures milling these logs. One day, I'll bring one of our Photographers with us to shoot some of this. Kind of hard to take photos and safely cut at the same time! We did splash a little water on a few of the boards as we pulled them off the mill.

Anyways - We ended up cutting about half of the log on site. A prior appointment forced me to cut the job short (see what I did there?) and haul the cut boards in my truck, and the remainder of the log strapped to the Norwood mill. Shhh. Don't tell Norwood. Technically, you're not supposed to carry anything attached to the bunks as you pull the mill. But, to be honest, the mill is build very well and with the small distance I was traveling, I took my chances.

Here is how I got back home with this load of ash. The log strapped to the mill:

And the boards we had already cut:

Notice my base here. I have mulch spread out (walnut mulch) to eliminate vegetation growth. On top of the mulch, I use 8x8x16" cinder blocks as a base. Usually, with 8/4 stock, I go every 3 feet. The cinderblocks are leveled to each other so the stock that gets stacked on them will dry flat. Any twist in the blocks will transmit through the drying stock. The flitch (a cut log) then gets stacked on the blocks. Stickers are kept in-line with the cinder blocks for the maximum amount of support possible.

Before turning in for the night, I ended up sealing the ends of the already cut boards and the log with AnchorSeal (my favorite sealer - found here: https://amzn.to/3fAnjvw ). This will help REDUCE the number of checks or cracks the ends of the boards get. Usually, I will try and paint the ends of the logs with anchor seal before I cut it (it's much easier to paint the round end of a log than individual ends of boards). However, when I'm sawing a fresh-cut log like this, I'll do what I have to.

Fast forward a couple of days, and I was getting ready to pull the mill down to another job. But first, I had to get the rest of this big ol' ash cut. The last board off this guy seemed to be the nicest.

This final board I ended up leaving a little thicker than the rest - about 3-1/2"-thick. The pith on most trees will end up cracking as they dry. But, the beautiful quarter sawn stock on the left and right of the pith usually end up making lovely leg blanks. So, it will take a little extra drying time, but it will be well worth the wait.

Thus comes the hardest part. Restacking all of the lumber that I just cut out of this log. The tractor with loader is usually a pretty big help with this part, but there's still a ton of lifting to be done. What I'm left with are these beautiful lawn ornaments - stacked flitches ready to try for a couple of years until they reach about 16% moisture content.

So - the moral of the story is to make friends with an Arborist. The guys out at Cro Outdoor Services are great guys, and arborists also have access to some beautiful material. If you're in central Iowa, you can check out CRO here: https://www.facebook.com/CroOutDoor

So, what's next with this sawmill? Well, that depends on what trees fall into my hands. Bojan and I are hoping to start partnering on projects - he gets the tress and drops them, and I mill them. Then we can market and sell these native Iowa hardwoods in the central Iowa region. If you ask me, that's a much better use of this natural resource than heading off to the dump.

Related Content - Best Porch Swings - Best Pole Saw