Having a good selection of clamps is essential. Most woodworkers will collect a number of F-style clamps, pipe clamps, and C-clamps. But some assemblies are made easier by using a more specialized clamp. Here are a few of my favorites.

Band Clamp

When it comes to clamping mitered boxes, a band clamp is my first choice. These clamps are available in a few different styles, but they all rely on a nylon strap to encircle the workpiece. You then tighten the clamp by turning a screw handle, as shown in the main photo, above.

Cam Clamp

A cam clamp is handy when you don't need a lot of pressure. Simply flipping the lever forces the cam against the jaw, tightening the clamp. But the thing I like best is that cam clamps are the most affordable option when your project needs deep-reach jaws. Get step-by-step plans to build your own clamps here.

Spring Clamp

Inexpensive and easy to use, a handful of spring clamps can be the solution to a number of problems. From gluing small workpieces to holding a stop block on a miter gauge fence, they're a shop favorite. Best of all, they come in a variety of sizes. You'll find everything from a 2" mini clamp to a 10" monster.

Frame Clamp

While frame clamps are very specialized, they really make it easy to glue up a mitered frame and keep it square during the process.

While frame clamps are very specialized, they really make it easy to glue up a mitered frame and keep it square during the process.

Once again, there are a few different designs, but they all use lengths of threaded rod and a right-angle caul on each corner. The cauls hold the mitered pieces in position while you turn the knobs to apply clamping pressure.

A big advantage of this kind of clamp is that you can adjust the pressure on each corner individually to keep the frame square.

Angle Clamp

Keeping the mating halves of a joint aligned and square is a common shop challenge. This angle clamp can take care of that, even with large, heavy workpieces.

The clamp actually grips each piece separately. You can't tighten it to draw the joint together. But it's open on the ends, leaving space for you to add screws or nails.

Hand Screw

It's hard to beat the versatility of a hand screw. I often use one to hold the side of a cabinet upright during assembly. It's also the perfect tool for holding small parts when routing. Another nice thing is that the jaws adjust independently, making it great for holding tapered or odd-shaped workpieces.

It's hard to beat the versatility of a hand screw. I often use one to hold the side of a cabinet upright during assembly. It's also the perfect tool for holding small parts when routing. Another nice thing is that the jaws adjust independently, making it great for holding tapered or odd-shaped workpieces.

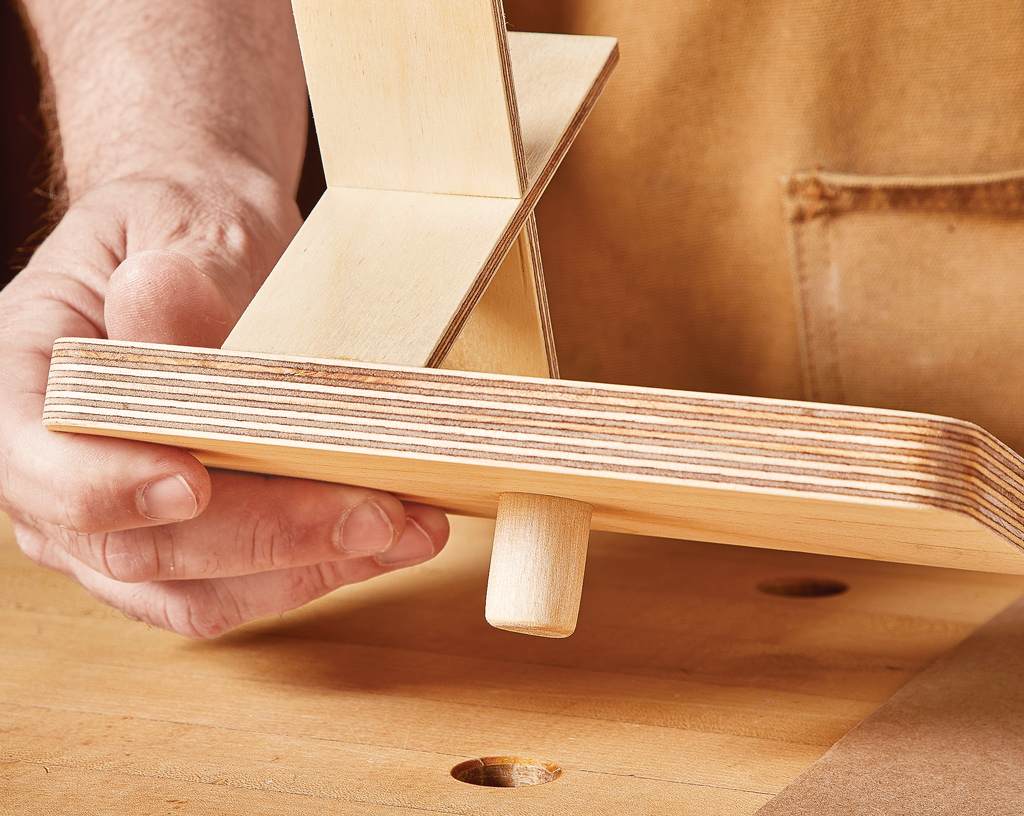

Edge Clamp

If you've ever struggled to add hardwood edging to a plywood project, then you'll appreciate a set of edge clamps. One look at the photo below and you can see why. An edge clamp is like having a third hand during assembly.

The design is pretty simple. Screws above and below secure the clamp to the workpiece. They also allow you to adjust the position of the third screw, mounted in the center of the bar. Tightening the third screw holds the edging in place.

With three or four of these, you can tackle most furniture projects with no problems.