One of the most important questions to ask when designing a shop project is, “What should it be made of?” It’s a question I hear a lot. Most Woodsmith shop projects are made from the assortment of materials shown here. Each one has specific qualities that make it ideal for projects that will see long-term shop use.

My first choice for building shop cabinets is Baltic birch plywood. Unlike standard home center plywood, Baltic birch is flat and more stable. It has almost twice as many layers as standard plywood. And those layers are all high-quality birch veneers with no voids. Plus, Baltic birch plywood is strong and holds screws well. Another advantage is it’s smooth. So projects look good in either a natural or painted finish. Although 60" x 60" sheets are the standard, you can now find 48" x 96" sheets, as well.

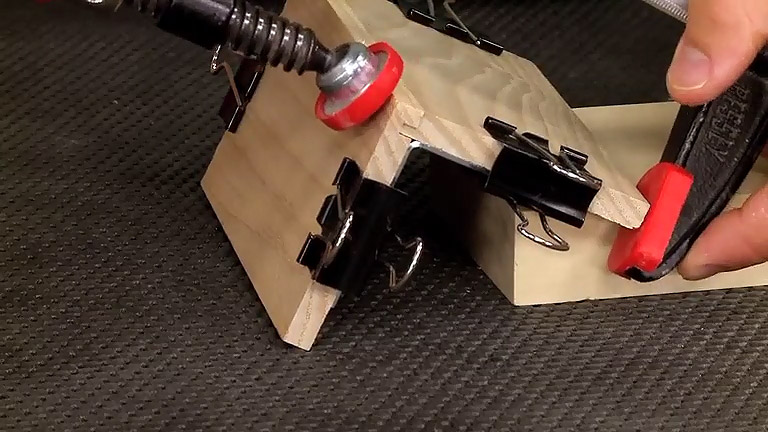

Not all sheet stock is used to make cases. One example is hardboard. Mainly, I use it for drawer bottoms and case backs. Since it’s smooth and dense, it works well as a top covering for workstation tops (seen in the photo above) and jig bases, too. The best quality hardboard is “tempered” and is smooth on both faces.

You’ll find a close cousin to hardboard in most shops and garages — pegboard. It’s a great way to add storage to your walls. Be aware that it comes in varying thicknesses. Look for the thickest pegboard. The thin stuff is more likely to warp over time.

Another option for building cases is medium-density fiberboard (MDF). It has a couple of big advantages. The first is that MDF is very flat and smooth. That makes it ideal for workbenches and tabletops, like this router table. A second benefit is that it’s heavy and absorbs shock and vibration. Another thing to like about MDF is it’s very inexpensive. So building shop full of projects won’t cost you a lot of money.

Another sheet stock I use is plastic laminate. This is the same stuff you find on kitchen counters. It’s inexpensive, tough as nails, and provides a low-friction surface that resists glue, finish, and solvents. That makes laminate perfect for router tables tops, assembly tables and workstations.

You can use almost any wood for shop projects. But there are two that see most of the action in my shop — Douglas fir and maple.

Actually, I use two very different types of Douglas fir. For many projects (like this workbench) common, construction-grade fir is a great choice. You can find it in many home centers. It’s inexpensive and strong, and if you take your time selecting boards, your project will look great, too.

When I want to build a “fancy” shop project, like this Tool Cabinet, I turn to vertical-grain Douglas fir. (You’ll find it at some hardwood lumber dealers.) The tight, straight grain has a look that can’t be matched.

The other wood I often use is hard maple. What’s not to like? It’s smooth, strong, wears like iron, and it isn’t likely to warp or twist. I like to use it for drawer boxes and jig fences.