Sanding straight edges smooth and square isn’t very difficult. But throw in a few curves, and things start to get a little challenging. The solution I turn to most often is a sanding drum mounted in my drill press. However, my first few attempts were less than satisfying. Instead of smooth, even curves, I had scalloped and burned edges along with loads of frustration. What I’ve learned since then is all it really takes is a few setup tips and the right technique to get top-notch curves.

Once you have a sanding drum set, how do you get the most out of it? Here are a few things to consider. The Right Size. The first thing is to select the right drum size. A good rule of thumb is to choose the largest drum that will fit in the curves of the workpiece. Most of the time this means I’ll go right for the biggest drum I have, as shown in the drawing below. What you’re looking for is a drum that matches the shape as closely as possible. However, if the project has a lot of tight curves, it’s a good idea to start with a small diameter drum to smooth the tight spots. Then switch to a larger drum to blend the contours together.

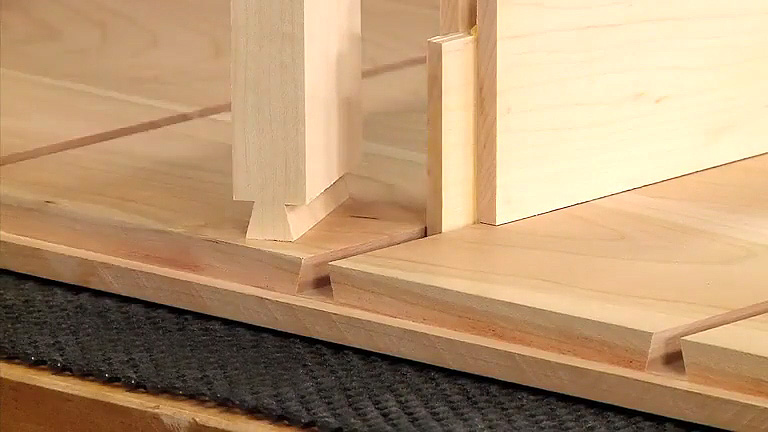

Next, I’ve found it helpful to add a large, auxiliary table to the drill press. This gives you a smooth worksurface and offers plenty of support for the workpiece. And a hole in the table lets you lower the drum to make better use of its entire length. The third item on the list is drum speed. A sanding drum works best when it’s spinning at 1250-1500 RPM. Anything faster may cause burning. Finally, one of the most important things to do is clean the drum regularly (inset photo, facing page). Built up dust and pitch can cause burning and shorten the life of the sleeve.

Because a sanding drum works so quickly, it’s tempting to attack the high spots and grind down to the layout line. What can happen though is that this creates large divots that are more difficult to even out. Plus, you’ll clog up the drum in no time. Instead, let the sanding drum do the work. The idea is to work up to the perfect edge with a series of light, skimming passes. Also, for the best control, move the workpiece against the rotation of the drum. Sometimes, no matter how carefully I rough cut a workpiece, I can still end up with a high spot or two. Just be sure to “glide” into and away from the edge to avoid creating visible “landing” spots on the workpiece.