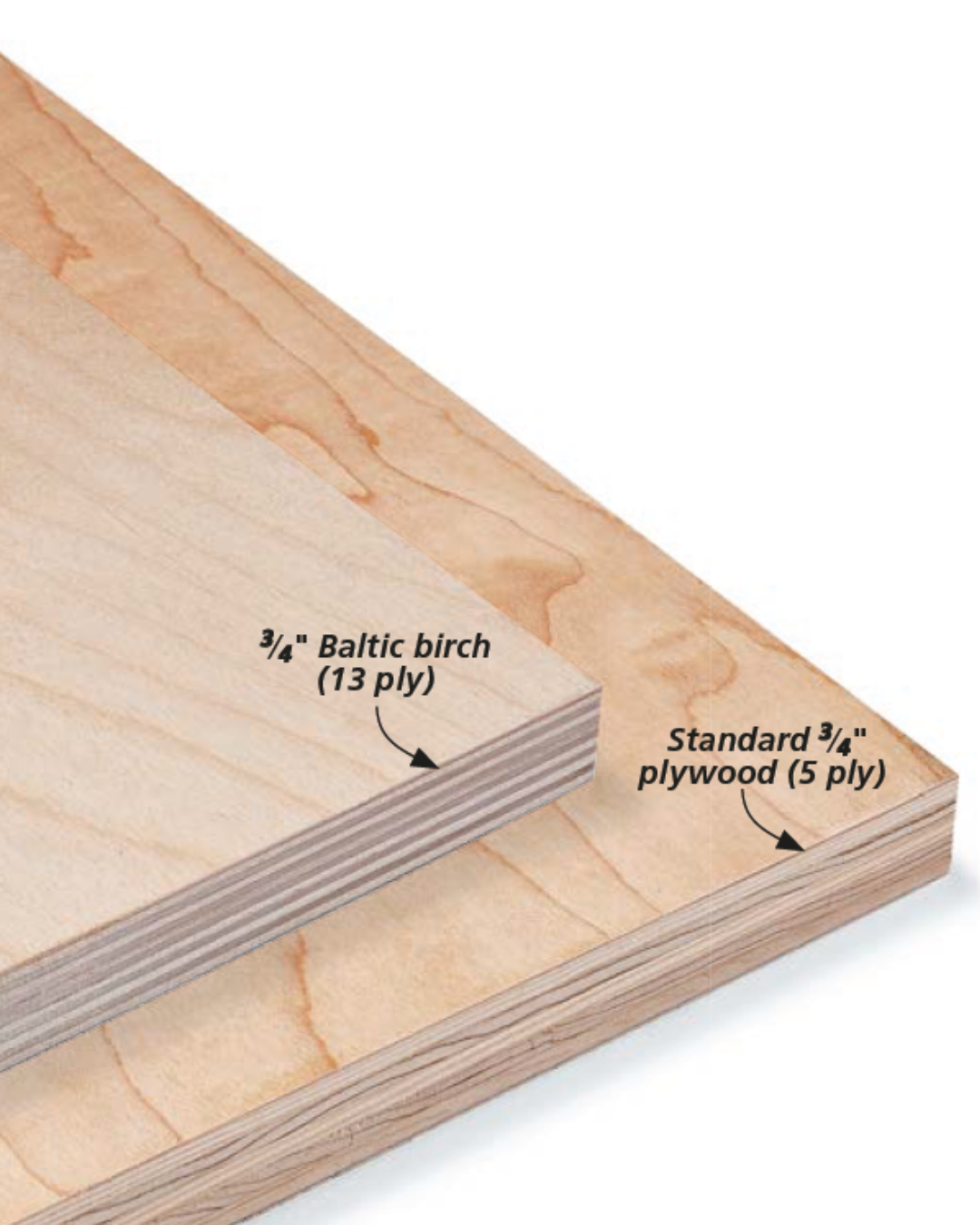

If you’ve been a longtime subscriber of ours, it will come as no surprise that we have a clear penchant for using plywood — more specifically, Baltic birch plywood. The reason for its frequent use may seem clear to some: strength, durability and stability throughout the seasons. However, let me take this time to dispel any pestering speculation concerning its validity and place in projects outside the shop.

|

| Baltic birch’s thin, hardwood plies make it strong and stable. |

The influence of its use, for me, can be attributed to the works of Donald Judd. Judd was an American artist associated with the Minimalism movement. Much of his work was constructed using industrialized materials such as plexiglass, iron, steel and plywood. Like Judd, and for many of us, the choice of material is often dictated by what’s readily available or accessible. And, rather than seeing this as a constraint, Judd viewed this as an opportunity to focus on the materiality of the material and how that translates into a practical form.

An early example of this methodology is Chair 84. It’s a painted plywood chair that was constructed in serial form – which was a common theme in Judd’s work. Originally, these chairs were built by a local carpenter using hewn pine found at a lumberyard. Geometric in shape, they contained cubic storage space directly below the seat, which varied in orientation to further accentuate the chairs proportions and the possibilities of the material.

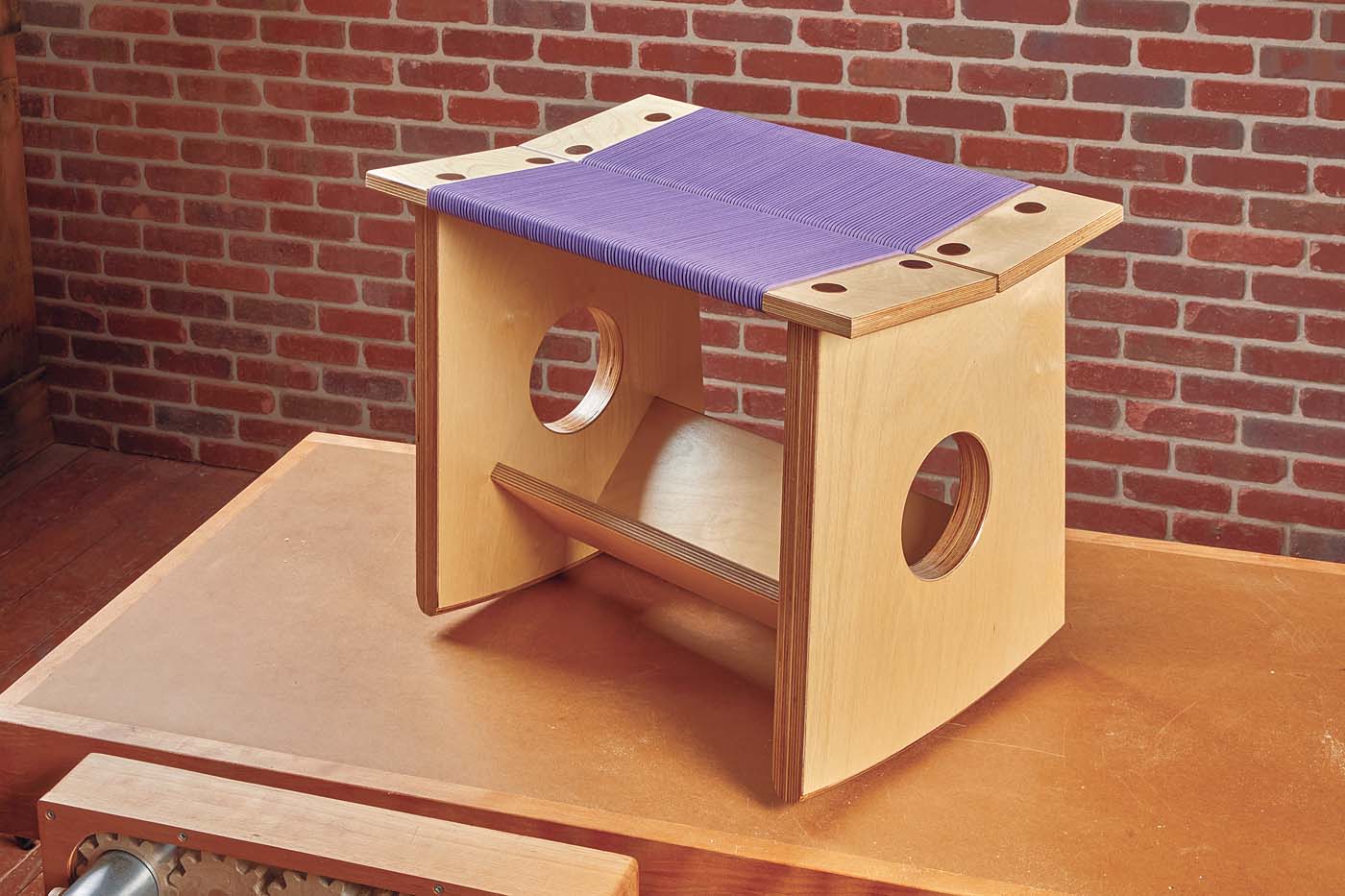

Furthermore, the contrast in the applied color against the inherent wood tones illuminates the aesthetic quality of the material’s composition. This is an approach I have attempted to explore and integrate into my own work. The photo on the previous spread is a version of a plywood chair I did for Popular Woodworking No. 258. This version, in many ways, embodies several of the physical characteristics of Judd’s Chair 84. Although, I wanted to take things a step further by using traditional exposed joinery in conjunction with modern sheet material. I found the concept of marrying these two elements ostensibly oxymoronic, but in a way that instigates the possibilities of plywood’s use in “fine” furniture.

|

| This stool takes full advantage of the materials from which it’s comprised. The interplay between |

Another process I have adopted is pairing birch plywood with hardwoods. The stool, shown above, is a project from Woodsmith No. 269. It consists of cherry hardwood and a manufactured product called BauBuche. This is a laminated sheet good comprised of layers of European beach.

This product has a high compression strength and an aesthetic resemblance to Baltic birch. You’ll notice the coloring of the plies accent the cherry, while the vertical orientation draws the eye up towards the halo-shaped form that makes up the seat. The union of these two materials provides an engaging visual juxtaposition as well as sense of strength and stability.

Going beyond the use of plywood as the main structural component of a piece, there is the option of further underscoring its composition through means of physical manipulation.

|

| A geometric, bismuth-type pattern is created using the cross sections of the plywood. The material’s physical composition then becomes the focal point. |

Take the spice cabinet in Woodsmith No. 262 as an example. Strips of plywood were cut (in various lengths) at a 45° angle and then reassembled to create the pattern you see here. The marshalling of these segments does two things: one, it creates a perceived surface quality — a sort of illusion of texture. And two, it generates a composition that becomes the cynosure of the piece.

Something else I enjoy experimenting with that helps redefine the perception of plywood is the treatment of this modern material in a conventional way. This can be done by means of using traditional joinery (exposed or concealed) more commonly seen in hardwood projects, or perhaps the introduction of a secondary material.

|

|

| Using modern materials and traditional techniques make for a unique and novel structure. Embracing the juxtaposition between the two deepens the connection between the past and future. | Introducing a bullnose profile to the rocking edge adds visual interest while minimizing friction using a single contact point. |

Take the example of the rocking stool you see above. Notice how the top registers with the base by way of over-sized walnut through dowels.

The contrast between the two materials is emphasized, visually, through the sheer size of the dowels. The construction method thus becomes a celebrated aesthetic component. You’ll also notice the woven paracord section that nests between the dowels. This continuous piece of static cord adds color while embracing its utility and compositional strength when applied as an upholstery.

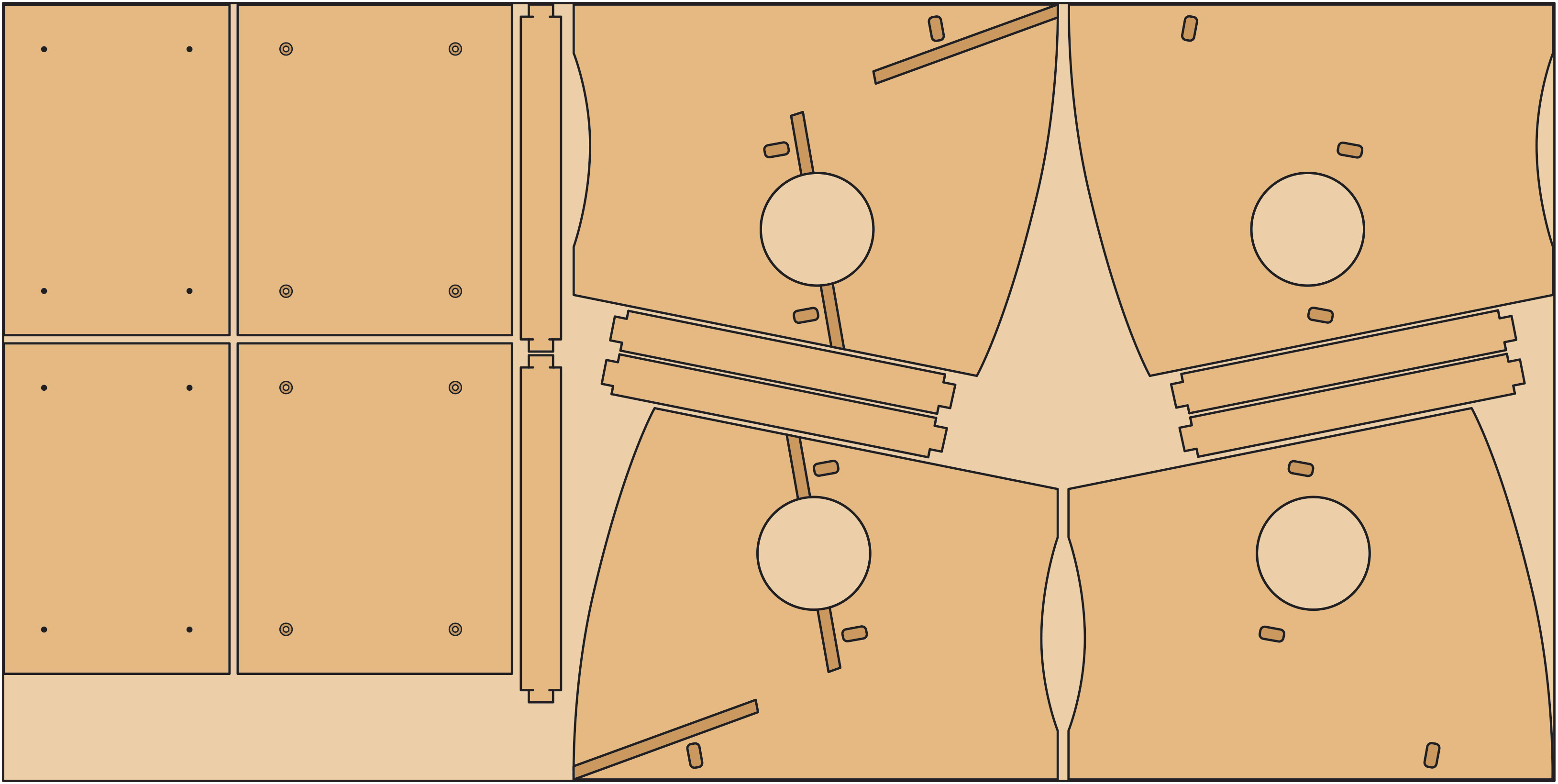

When thoughtfully combined, these materials and construction applications work in tandem to create a striking, well-balanced piece. What I have come to appreciate about this method of designing is the initial impression of a limiting condition — that being the area of a 4’x8’ sheet of plywood. However, when confronted, it impels one to take a more conscientious approach to the design process. The spatial parameters are preset: now, the challenge is yours to make the most of the space.

GETTING THE MOST FROM YOUR MATERIAL

An exercise I have adopted and put into practice through out the last few years is using a standard 4’x 8’ sheet of plywood as the catalyst for design. The objective being: utilize as much of the sheet as possible with minimal waste. One of the unique elements of this assignment is the nature of its framework, which forces one to design within the limits of spatial availability.

The chair, you see here (Popular Woodworking No. 258), is an example of this exercise. Working within these parameters influences one to be concscious of the whole. This begins with a process called “nesting” which aids in not only eliminating waste, but helps establish the procedure in which each piece is cut from the sheet of plywood. It’s like designing a giant jigsaw puzzle, but one you can sit in upon its completion.

|

|