Denmark & Sweden

Later this year, Logan and I are hosting a tour to Demark and Sweden. It's September 20-27, so we'll miss the crazy tourist season. In addition to the places we visit, there'll be plenty of time to enjoy the scenery and cities of these two countries. We'd love to have you along.

The Woodworking Witch

Last week, Nate, the podcast editor posed this question: If a woodworking witch forced you to choose one type of woodworking to do for the rest of your life, what would it be?

I pictured this witch from the Pixar film Brave ... cuz she's a woodcarver.

My answer: "Plank" woodworking. Projects and objects made from a single piece of wood. That may be a plank, a branch, and section of log.

Sure, you could say that about just about any project, but I'm focusing is down to items like: shrink pots, carved bowls & trays, sliding lid boxes, spoons & utensils. These are smallish items that place a high value on practicality and creativity.

I enjoy working with hand tools and when I make these kinds of projects, there's a strong emphasis on skill, closeness to the material, attention to grain direction, sharpness, and a work with my whole body.

I'd love to hear what you think.

Spoon Fix

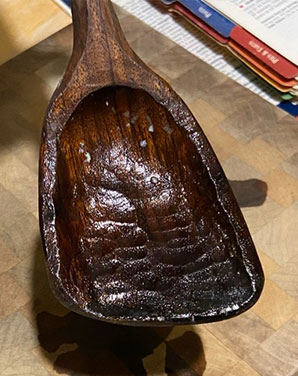

Several years ago, I carved a bunch of spoons for Christmas gifts. Along the way, I made a few for our kitchen. For the most part, they turned out pretty well. Like all woodworking, they reflect my skills and eyes at the time. The general-purpose cooking spoon and a spatula I made see near daily use.

Now that I know better, I wanted to see if the design could be improved. After chatting with Chris, he suggested soaking the spoons in water. What was supposed to be a couple hours turned into overnight soaking. It's all good.

The spoon bowls carved wonderfully. In addition to some curved blade knives, I used a palm gouge from Jason Lonon. Lovely tool. I thinned out the front of the spatula and deepened the scoop portion. On the cooking spoon, I improved the hollow and thinned out the rim. Well maybe too thin. One section is less than 1/16" and a little flexible. I feel it but you don't see it unless you look close.

The best part is I can always make a new one after these wear out.

Transcript

What we said, and how poorly we phrased it.

Phil Huber (00:03.439) Here we are again, everybody. It's the ShopNotes Podcast, episode number 260. On today's episode, we're gonna respond to some listener and viewer feedback, questions, comments, and smart remarks. It's also a very magical episode. We're gonna talk about some things that are going on here at Woodsmith and Popular Woodworking, and also just get some general shop updates.

This podcast is made possible by the folk that subscribe to Woodsmith and Popular Woodworking, as well as our membership programs, Popwood Plus and Woodsmith Unlimited. You want to check those out online, see all the details, great stuff you get with it. And we'll put a link to that in the show notes page. So for now, we'll get started with last week's episode and a few questions and comments from there.

Phil Huber (01:06.469) James Scottingham says, when we bought our house almost 35 years ago, we had a katulpa tree in the front yard right next to the street. It was large and pretty. It too had a large hole in the middle, but instead of cement, it had empty beer bottles. I don't think the tree grew them, although we don't know that for sure. The neighbors liked the caterpillars for fishing bait. Unfortunately, a logging truck hadn't tied down its load properly, hit the upper branches,

and split the tree in two. The tree died shortly thereafter. I missed the shade when I mowed the lawn. And yes, there are two species of katalpa, a southern one and a northern one.

of

Phil Huber (01:51.995) Boys says cold here too in upstate New York minus 40 wind chills and up to 24 inches of snow. I'm a little jealous for the snow part. Logan, can't you insulate the area above the frozen pipe where the air is leaking in or add insulation on top of the pipe to stop the downdraft? And then Phil, if you could be more specific on what auger bits you want, I'll check the used tool store where I volunteer to see if we have it.

All our tools are donated often from long time woodworkers who no longer use them. So Logan, you want to take the frozen pipes part?

Logan Wittmer (02:29.248) Yeah, I yeah, absolutely could. It was and that was my plan. I just was chasing down the areas is the biggest thing. I was just chasing down those areas where it was dropping down on top of the pipes. Actually, what I did is I went in and use that foil faced bubble wrap, I guess, for lack of better term. It's like foil face on both sides of the layer bubble wrap in the center comes on a roll.

And where my pipes were situated was right below where my T111 starts. So I cut that foil faced insulation, maybe a foot and a half long to fit in between the studs. And then I stapled it to the bottom of the T111 and then draped it around the pipe. So any air that would potentially fall down the wall would hit that and be directed behind the pipes.

The saga of the frozen pipes, I think has concluded. We had several days of negative temperatures and after doing work and insulating, haven't had a single problem since. So I did also bury in a resistor style pipe heater, which is just a Sony five foot roll of heating element. I wrapped that around the pipes the whole way.

and the pigtail is in my utilities room. So if for some reason they do freeze again, I can just plug it in and then I will know what the threshold is to plug it in and turn it on.

Phil Huber (04:06.095) Nice. All right. And then, yeah, I wasn't really looking for a specific auger bit. It's the auger bit extension. They have two lengths. One is a 24 inch one, which is way too much. And then an 18 inch one is the one that I'm looking for. And it's to accept the square shanked auger bits rather than like a hex shank bit extension. Like you can find, you know, Lowe's

Home Depot kind of place here. Bot Dad says, for gifts, I keep a running list of stuff that I want to get eventually on Amazon that my wife and daughter both have access to. That allows me to watch the list when it's not right before Christmas or my birthday to see if anything has a big discount, then I'll just buy it myself.

There you go. And Harold McDonald says, whatever happened to the last installment of Phil's shop tour? Last I knew John had it scheduled to go out within days. And that was weeks ago. Really dropped the ball there, John. Come on.

Logan Wittmer (05:15.95) It's I hope he said that right. That Phil. OK, good.

Phil Huber (05:20.025) Yeah, he did. Yeah.

John Doyle (05:23.352) Yep, it's scheduled as of right after this podcast, I guess. yeah, that's one of those things that fell through the cracks.

Logan Wittmer (05:26.926) Yeah

Phil Huber (05:32.304) Perfect.

John Doyle (05:40.086) I feel like Phil's been sitting on that comment just to read it. In a public forum. I feel bad. He's been patiently waiting to see the rest of this and just been holding it. All right.

Phil Huber (05:40.323) Phil Huber (05:43.619) Yeah, no, that one, right. That one was a new one, like just today, so.

Phil Huber (06:00.004) As always, questions, comments, and smart remarks, we appreciate those. You can send those in an email, woodsmith at woodsmith.com, or put them on the YouTube channel. We have a couple other ones here, one that I wanted to get to.

Mike Thomas says, I just wanted to get everyone's comments and input on double-sided tape. Has there ever been a study on how much tape to use? I was thinking about this while listening to your podcast and struggling to get my pattern separated from the finished routed part. Thanks for spending time doing the podcast.

John Doyle (06:45.004) Double-sided tape is one of those things that I struggled with early on. Because I've mentioned I have trust issues and like there's like no way that this tape is gonna hold on this template. I know it's gonna come off so I would put on way too much tape like cover the whole thing. Probably even use clamps on top of the tape. And yeah I had the same thing where I was like okay now I can't get this template off so I think I've

I've, it's earned my trust and I've, know, it's a couple of squares along the edges. Usually holds kind of depends on, um, like how smooth the surfaces are that you're connecting, how clean they are, um, how flat they are. So you kind of have to experiment a little bit.

Logan Wittmer (07:29.667) Yeah.

Logan Wittmer (07:36.748) Yeah, I am a I'm a ship ship guy. That's what I do. So like two ships. Yep. Yeah, I think that's about the perfect.

John Doyle (07:40.856) Two, two, two gyps should, should do it.

Phil Huber (07:48.902) I usually do like short strips of tape, probably about like two inches long, just periodically, maybe like every eight to 12 inches along the length. However, if there's something where there's like a really significant curve or something in the pattern, then I make sure that that section definitely gets a good amount of double-sided tape there.

just because I don't want the pattern shifting. Like if it's just a straight line that you're routing against, I feel like I'm not gonna be really pushing as hard against the bit on there. But when you get to those curves, like you wanna make sure you keep the bit engaged on that curve. Also, just the last couple of days, I was using some double-sided tape to hold a small workpiece down on the workbench so that I could use a hand plane on it because it was

a wacky shape and really thin. So it's not like you can use bench dogs or stops or anything. the for that then I'm using like it was like the whole length of that part, which was only like four or five inches long. So

Logan Wittmer (09:05.742) See, I prefer two continuous strips, probably full length of my part, depending on how big the part is, just because I don't want multiple littles, because I hate more than anything peeling the back off of it. Like, I'll just pull them off. I am a fan of a putty knife to get parts apart. Like you would think you can get your fingers under there and just pry it off and you can, but it's like 50-50 whether you break your hardboard pattern or not.

because sometimes that is sticky. But I agree with John's like it depends on how smooth the part is. The smoother the part, the less tape you need. But I've also found if you have a rough cut edge and there's let's call it a burr for lack of better term and you have a burr on the ends.

that can hold the surfaces apart enough that that tape won't grab, because that tape's really thin. Like the stuff we buy is super thin. You know, you can get thicker like carpet tape would be thicker. And a lot of people like to use carpet tape, you know, so you wouldn't maybe have that big an issue. But yeah, I I'm like, give me like a good couple of eight inch strips of tape. And usually that's plenty for whatever I'm doing.

Phil Huber (10:04.399) Yeah. Right.

Phil Huber (10:24.931) Yeah. Yeah.

John Doyle (10:26.722) Yeah, it's funny you're talking about taking off the backing of all that tape. And it reminds me of I ran into a guy in public. I don't know. This is probably 10 years ago. And we got to talking that I worked on the Woodsmiths shop TV show for some reason. And he loved the show. But he only had one comment. He's like, the only fun thing I find unbelievable is how easily you guys take the back off the double sided tape. It's like, it's just not believable.

Like that's where you lost me because we would always peel off a little corner so Don could like grab it and take it off and not struggle with it and But that was the one thing that he found unbelievable not that we built an entire project in 23 minutes on the TV show It was how easily we got the back off the double-sided tape so TV magic

Phil Huber (11:22.107) On a related one, Bill Weaver writes, I've been a subscriber of Woodsmith for 40 years.

One topic that I've either missed or forgotten is regarding the use of tape, specifically double-sided tape for duplicating pattern making. I see it referenced often. What kind of double-sided tape should I get? I most often run across the Scotch brand, which is cellophane tape with adhesive on both sides. Is there a better tape that should be used in working with wood? If so, what kinds are advisable and where should I be looking for them?

Phil Huber (12:02.059) And I found the roll that we had, and normally it has on the inside what it is, but where this one is cut does not have it. I think it's intertape, right? Or itape.com.

John Doyle (12:12.664) Yeah. Uh, I like enter tape group or cause it's like a three letter thing. I T G or

Logan Wittmer (12:14.894) I'm looking at my Amazon order real quick to see what I've ordered.

Phil Huber (12:21.881) Yeah, we'll put a link in the show notes page for the tape that we have. The stuff that we have here that looks like about a three quarter inch wide will vary rolls for what we get like three quarter, one inch or sometimes like a two inch wide roll and have those around. This isn't, it's more like masking tape.

Logan Wittmer (12:46.978) Mm-hmm.

Phil Huber (12:48.655) like old school masking tape, both in thickness and consistency. It just has like adhesive on both sides.

John Doyle (12:58.488) Intertape Polymer Group, IPG is the brand that we use. So it's been good, used it for years.

Phil Huber (13:02.585) There we go.

Logan Wittmer (13:09.196) Yeah, I actually have some that I order off Amazon that I really like. It's very similar to the IPG stuff. That stuff's a little bit more expensive, I think, and it was just easy that I could just order off Amazon. But it appears that that company doesn't sell it anymore on Amazon, which is kind of annoying. So.

John Doyle (13:31.042) Yeah, I think.

Logan Wittmer (13:31.208) But what you don't want to get is you don't want to get any of like the 3M stuff that is like a clear or a foam on the inside. That is not what you want. That is what they call permanent.

John Doyle (13:40.748) Yeah, the foam double sided tape, that's good for attaching false fronts on drawers. It has some grippy squish there and you can kind of still maneuver a little bit. yeah, once you get that stuck down, it's pretty permanent and messy to clean up. So I wouldn't use it on templates and stuff.

Logan Wittmer (13:49.964) Yes. Squish. Yeah.

Logan Wittmer (14:01.474) Yeah.

John Doyle (14:07.17) But think you can get the IPG tape off of Amazon. Maybe. least you could.

Logan Wittmer (14:11.214) I don't see any.

Phil Huber (14:14.821) We had it linked on with our store for a while.

John Doyle (14:16.812) Yeah, I'm looking right at my Amazon and I see it. So we can put a link.

Logan Wittmer (14:20.91) Well, if you you if you just Amazon like double sided tape, they do sell X fastened double sided woodworking tape. It's one inch wide, a three pack for twenty two bucks. And it has really good reviews.

Phil Huber (14:37.263) Yeah, I think Ben over at Fine Woodworking loves the X-Fast and stuff.

Logan Wittmer (14:43.266) Yeah, and I can have it here today between 5 and 10 p.m. in case you're wondering. Yep.

Phil Huber (14:48.089) Whoa.

John Doyle (14:49.496) Okay. Did they make a different tape for turners? Is that a thing? Turning, no? Okay.

Logan Wittmer (14:54.794) No, not really. The only time you would be really, think, trying to do that would be like if you're doing like a split turning, but then most people, the consensus is to glue heavy craft paper between what you're doing, because then you can split it.

Logan Wittmer (15:15.0) CA glue, CA glue is the Woodturners double sided tape.

Phil Huber (15:19.451) you

Phil Huber (15:23.897) You don't want to use the cloth-backed legit carpet tape, because that is kind of like welding your two pieces together.

Logan Wittmer (15:29.12) No, I used to.

Logan Wittmer (15:33.804) Yep, learned that very quickly.

Phil Huber (15:37.306) And at that point, your friend is mineral spirits to soften the adhesive to get that up. And don't be tricked by low odor mineral spirits. Low odor mineral spirits is just a scientific word that means never evaporates and leaves a greasy film.

Logan Wittmer (15:50.946) Yeah.

Logan Wittmer (16:00.609) Yep.

Phil Huber (16:05.763) Anyway, next segment that I want to talk about is an upcoming woodworking tour that Logan and I are doing to Denmark and Sweden in September, end of September 20th to the 27th. The email and the sign up site just went out this past week and

Logan Wittmer (16:16.258) Mm-hmm.

Phil Huber (16:34.617) We're both pretty jacked about it. Logan did the preview trip sort of over Christmas, seen a couple of the sites there, was in Sweden. And we have a pretty great lineup set up for what we're going to be seeing there. So yeah, run through it real quick.

Logan Wittmer (16:50.808) Should run through it? OK, so basically everybody is arriving September 20th at the Copenhagen airport, so you are responsible for your own flights. So if you want to fly premium comfort or first class or business class, you're welcome to do that. You are responsible for your airfare. Great way to use your Delta or American Express miles. Not sponsored, but should be. And we will be having a welcome dinner, so we'll meet everybody somewhere around Copenhagen.

to do a big group dinner, which would be super cool. So that's Sunday. That Monday, we are going to the Roskilde Museum of Tools, as well as the Viking Ship Museum in Copenhagen. So that is a working kind of a working boatyard where they are rebuilding Viking ships in like period historic manners. So the people will be hewing beams. They will be doing all that stuff. And I

Don't quote me on this, but I believe you can actually pick up an axe and hew a beam if you want. So which would be pretty sweet. So that's Monday that so there's two museums, there's the Viking Ship Museum and the tool museum that day. I'm guessing there will be a little bit of free time. I know those two are very close together, like they're kind of kitty corner of each other. So I think there will be time to go explore Copenhagen a little bit if you would like on your own.

On Tuesday, we are doing the Design Museum of Denmark and visiting the Møbler workshop. So kind of get to do some hyper fixation on the Danish modern design and some chair stuff, which will be super cool to see some of that. There is free time in Copenhagen that day as well. And then you're on your own for dinner. So if you want to go find something very Danish, you can.

Monday we will have a group dinner after the tool museum. And then we are Wednesday heading to the Sjöberg workshop where they build the work benches, which would be very cool. There will be driving so we will be heading, think that day we are heading from Denmark into Sweden.

Logan Wittmer (19:15.902) And we're going to visit the workshop. And then there is a another workshop. have to remember. It's been a while since I set this up. The. For yes, which is a handmade furniture workshop in Sweden. So that will be a working woodworking shop making furniture. So it'd be cool to have a tour of that. And then we have the dinner at the hotel when we get into Sweden.

Phil Huber (19:25.317) the Gemla fabricers.

Phil Huber (19:31.629) yeah.

Logan Wittmer (19:45.922) Thursday, we have a design and craft museum, the Rosca Museum of Design and Craft. And then this is one that I'm interested in is the Sätergläntan Museum or Institute for Craft. So this is a large craft school, which all this is all of this is available on the website where you can kind of go through, click through and see a lot of the stuff.

This is basically a Sloyd arts and crafts school. So a lot of kind of that historical Scandinavian type of work is taught here. So it would be very cool. Now, maybe my favorite day is going to be September 25th. That is Friday. We are visiting the Grantsworth Brooks forges where they are forging axes.

still a hundred years later. if I remember right, the, the Gränsfors Bruk Forges have been forging for hundreds of years. They started doing axes in the early 19 hundreds and they are still doing them all by hand. so this is where Logan will be bringing a suitcase full of death home because I will be stuffing the suitcase with as many Grands Forth Brooks axes as my wife will allow me to buy. So.

that will be very cool. and then we have a, I believe a sawmill tour that day as well. So that is. Yep. Which is going to be super cool. Like traditional Swedish sawmill. and we will be doing a dinner at the hotel with the group there. and then Saturday, we ended up in Stockholm, Stockholm, Sweden. so over this trip, we are driving, we're taking the tour bus.

Phil Huber (21:20.217) Yep. Headlands, timber. Yep.

Logan Wittmer (21:44.47) So there is a tour bus that is bringing everybody that's on this trip to these different locations. So we will be starting in Copenhagen doing our several days in Denmark, and then we'll be driving into Sweden and then up through Sweden. We are in Gothenburg and then we are driving across Sweden to Stockholm. Yep. Yep. Yep. To Slatergatan and then into Stockholm. When we get to Stockholm,

Phil Huber (22:06.373) Cedar Glen. Yeah.

Logan Wittmer (22:13.902) I don't know if we get into Stockholm on Friday or Saturday, but you do have on Friday. We have the Skansen Open Air Museum, which is more like a living history type museum. Yes, yes, exactly. And then we have free time in Stockholm and dinner at the hotel. then Sunday, the 27th is the departure day. So if you wanted

Phil Huber (22:26.681) Yeah, a little along the lines of like a Colonial Williamsburg kind of feel to it.

Logan Wittmer (22:44.184) There is absolutely nothing keeping somebody from staying a couple extra days in Sweden. I was, as Phil mentioned, I was just there with my wife and a couple of friends over the winter break between Christmas and New Year. And Sweden was the one place that we wish that we had spent more time. We were there for particular reasons and we were only there for a couple of days. Sweden is absolutely beautiful. So I am very excited for this trip.

And we're kind of rubbing it in the final woodworking guys faces because they're just going back to England, which also very cool trip. Yeah. Yep. So, no, it's going to be a very cool week long trip in Sweden. The only thing that you are responsible for as a traveler is to get your airfare.

Phil Huber (23:22.297) That was a super cool trip. I loved every minute of that one.

Logan Wittmer (23:43.052) And then there is, I think, maybe one day where you have dinner on your own and you have some free time in Stockholm and in Copenhagen. So come. Grab a grab a room. have the option to buy either a single occupancy or double occupancy room. So if you are a person that likes to just relax by yourself in your hotel room at night with nobody else around, you buy a single occupancy. If you don't mind bunking with somebody.

separate beds. You can double occupancy a room and everything's covered hotels. Most of the dinners, the tour bus. We have a guide. I don't know if we're bringing Kitty or who's going with us. Who the guide that we're going to have with us. But then Phil and I will be there. So which what more needs to be said?

Phil Huber (24:34.917) Yeah.

Right, that's what I'm saying is we had several people on the England tour last year who stayed a few extra days, did some traveling throughout. So if you want to extend your European vacation, totally do that. That's not a problem for that kind of thing. yeah, the England tour was great. We had a number of spouses along with us and I don't think a one of them

Logan Wittmer (25:02.124) Yeah.

Phil Huber (25:08.485) did not enjoy the trip, even though there was a lot of woodworking nerdery going on in looking at all the different museums and schools and businesses that we were looking at. It was just a super cool trip, lots to see. And then like Logan said, and this was something that I experienced on the England tour is just being able to see the country itself. We did quite a bit of driving.

Logan Wittmer (25:10.242) Yeah, for sure.

Phil Huber (25:37.549) on the England tour, we're going to do some driving here with the tour bus. And having the tour bus means that you can look out the windows and see the mountains and the coastline and the fields and forests and all of that sort of thing.

Logan Wittmer (25:46.476) Yeah.

Logan Wittmer (25:52.142) Yep. Yeah. The just some of the logistics. So if you anybody that is interested in reserving spot, because we do have I don't remember how many people were limiting this to, I think 30 is what we're limiting it to, because obviously we have a bus that are driving people around. We the deposit is due by June 19th, and then you have till the end of July for final payment. So.

that will at least reserve your spot. I think this is this is this is going to paint me in terribly sure. This is how I would sell this to my wife. Like, hey, we don't have to do anything other than go. But then as a woodworking nerd, I get to go see all the things I actually want to see that if I say, hey, let's go to Sweden. She's not going to let me go see all this woodworking stuff. Like she's not going to let me go to the Grantsworth, Brooke forges and watch them forge axes like. But guess what?

If we don't have to do anything other than show up, you should let me do it. So, yeah.

Phil Huber (26:53.019) Right. Yeah. Yeah. So there's several people that have asked us about this tour up until now and we haven't had a website to point them to. Ryan, looking at you. PuppyDoc, right there. There was a guy from our tour, the England tour last year, he's commented on our site. I can't remember his name off the top of my head and it's making me feel a little bad right now, but.

Logan Wittmer (27:05.55) Yep. Yep, there it is.

Logan Wittmer (27:16.706) I said we have sold. Yeah, we we've had the ticket sales up since we go up Sunday. Saturday over the weekend, and we've sold five of the spots, I think, so far. So I would be surprised if we don't fill out all the spots on this. So it'll be. It's going to be awesome. So.

Phil Huber (27:24.667) Over the weekend. Yeah, it was like Friday or something like that.

Phil Huber (27:39.663) Yeah. It was a lot of fun just hanging out with people and talking about woodworking, even as we're driving along, you know, it was kind of like a Q &A time where there was one part of the drive where it was just like rapid fire questions back and forth to Mike and I about stuff and so.

Logan Wittmer (27:47.245) Yeah.

Logan Wittmer (27:57.841) Yeah. Yep. And it will, yeah, it'll be very cool. I, I enjoy the ability to take a group of people to a location like this, where a lot of people would love to go see, like there are a lot of people are like, I would love to go see Sweden. I would love to go see Denmark.

But they're not necessarily going to go do that by themselves because there's a lot of like, well, what do I do? Do I have to figure out where to stay? You know, do there's language barrier stuff? Yep. We got you. We got you. So.

Phil Huber (28:26.939) How do you find these places?

Yeah. Yeah. And a lot of places where it's it's easier to get into them because we have a tour than it would be if you were going to try and do a tour on your own.

Logan Wittmer (28:37.986) Yes.

Logan Wittmer (28:41.462) Yeah, I don't think you can just go to the show, Berg's place and be like, Hey, I won't watch you guys make work benches. I think they're gonna look at you like you're sir. Do you need help? Yeah. Yeah. So it'll be cool.

Phil Huber (28:51.835) They'd like, no creeper, get out.

Phil Huber (29:00.441) All right. All right. The next part of podcast, next segment that I want to deal with. This is a question that our editor, podcast editor, Nate Gruca asked last week in the studio. John probably doesn't remember the question, but he might. Logan wasn't here while we were filming that day, so he won't know this is a surprise to him.

But if you've seen the Pixar movie film Brave, that was the one set in Scotland, in it was...

Logan Wittmer (29:37.474) Mm-hmm. Mm-hmm.

Phil Huber (29:46.084) a magical woodworker, some might call her a witch who did wood carving of bear themed accessories in there. So Nate's question was, say this witch woodcarver came up to you and said that you would be limited, you had to choose one type of woodworking to do for the rest of your life to the exclusion of all others.

What would it be?

Logan Wittmer (30:16.878) How are we defining type of woodworking? Like you're only building chairs?

Phil Huber (30:19.791) See, that's the thing. She's a witch, not a monster. it could be you get to answer, she's allowing you to answer that question.

John Doyle (30:21.4) you

Logan Wittmer (30:25.291) Okay.

John Doyle (30:30.434) Yeah. I do remember when he brought this up and I think I said casework would be my thing just because it seems like it's the most useful thing maybe in my life. I don't know. Casework. But then, yeah, as we were...

Logan Wittmer (30:38.082) Hmm.

Phil Huber (30:47.567) Okay, I like that.

John Doyle (30:51.832) We had mentioned this the other day, like last episode, we're like, I can't make, Logan was saying, I can make money doing, we could make money doing this. And I was like doubting, like I could not. And it's like, when I, every time I do, cause on this cart that we was doing for the, for the TV show, we had, you know, how to build a case and then all these drawers and then fitting all of the, the false fronts on them and getting them all evened and.

It's like, I think I could do that as my lifetime thing, is like figuring out how to, because it always goes together like a puzzle. Like where do you start? How do I attach the drawers? Get them all even, even gaps, adjusting and fitting and it's like.

Phil Huber (31:35.696) Well, and that's what we were talking about is in between like trying to figure out what segments of that cart we were gonna show and when, especially with the false fronts, I was like, well, let's start with here. And John's like, no, I wanna start at the bottom and work the way up and because one, two, three reasons. And I was like, okay, well, that totally makes sense. So yeah, I can see that.

John Doyle (31:59.82) Yeah, it's a fun, it's always a fun problem solving exercise of like how you're gonna do that and make it look good. yeah.

Phil Huber (32:09.017) Okay. All right. So casework. Logan.

Logan Wittmer (32:12.686) I want to say world class. I'm only going to do world class woodworking. But but we know like that's not the case. No, I I think. So I'm going to take this the same same route that John is going like, like if I was going to do something to make a living, I really like the idea of being a production woodturner. But not not like the. Like

Phil Huber (32:15.555) Wow. Yep. Yep. Yep.

John Doyle (32:16.344) You're already living the dream. You're living the dream right now. You're doing it.

Phil Huber (32:37.765) Okay.

Logan Wittmer (32:42.342) Steve Jones is a a woodturner out of England. His his YouTube and Facebook group is the Woodturners. But he's doing a lot of he does a lot of spindle work. So he's doing a lot of like balusters and, you know, stuff like that. And like, that's not what I want to do. I want to do spindle work. Like I'm thinking more of like a Glenn Lucas style or a Mike Mahoney style where you're a production bull turner. Like you're just you're turning bowls. Like I really enjoy. The idea.

So so Glenn Lucas is a a woodturner out of Ireland. He kind of made his career doing production with turning, just turning bowls and platters and stuff like that. He's evolved that into teaching, opened up a woodturning school in County Carlo, maybe, and is doing that now. But he also still still keeps up with his production turning.

And he has started to release a series on YouTube called Life of a Woodturner, something like that. And episode five just dropped last night. They're like 35, 40 minute episodes. And it's just kind of like, what's he doing during the day over a three or four day period as a production woodturner? And he is, you know, one of the episodes he was going and picking up a bunch of logs that a tree surgeon had had felled and had stashed for him. And he went and picked those up the next day. The next episode was him.

saw milling on his log of soul sawmill a bunch of that stuff into blanks and how he is he has the mentality of like a production Turner so he's sawing this material for himself to use he's not cutting this for sale he's cutting this for him as a Turner to make the most money out of so he's he is keeping stuff that I wouldn't keep because he's like I can cut these into you know egg cup blanks so I can make egg cups stuff like that I like that mentality

And yeah, just the I like the repetition of it. It's it's different enough because every every time you're turning something, it's slightly different than the one before you. have I mean, you have standard. I'm cutting this this tree into four and a half inch by 16 diameter bulb lengths. Cutting this one into five by 20s like you have that. But every shape is just a little bit different. All the woods just a little bit different.

Logan Wittmer (35:08.012) you know, every finished piece is just a little bit different. And I like that mentality. So I think that's where I go with it.

And it's what I enjoy. Like I really enjoy it.

Phil Huber (35:18.671) Right. Well, and I think having watched you turn sometimes multiple pieces here for something like...

There's definitely a

There's definitely like a big steps progression in your education. But even once you start doing multiples, it's like, okay, I need, I know what I need to do in order to get to this part of the form super quick. Like this is the body motion. This is where the tool needs to be, where the tool rest needs to be speed, all that kind of stuff that yeah. Okay.

Logan Wittmer (35:54.498) Yeah. And the closest, I think the closest that I've gotten to that in my woodworking, like I love doing bowls, love doing bowls, love doing vessels. I'm looking at a bunch of them that sit on top of my bookcase right now.

The closest I get is when I'm doing like a run of like shaker knobs for like the work bench or for the vanity or something like that. Like I might only be making, you know, a dozen at a time for a set of six drawers or maybe five drawers and a set of cabinet doors. But very quickly you're like, all right, maximum diameter length, minimum diameter, cove round over done. And like you get into that like steps, you know, again, I don't, I,

I very much admire Steve Jones and how he does his stuff as a production. I'm going to call Steve a production spindle turner. That's probably, think that's a majority of what he does. And I've never seen somebody better with his skew chisel, like unbelievable. And he's turning like the, like pine and stuff like that with the skew chisel. And it is just absolutely flawless.

But yeah, I like the steps of like, do I, how do I make this efficient? How do I, how do I eke out four more bowls a day versus, you know, maybe if I, do I have three bowl gouges sharpened or do I have two, two finishing bowl gouges and one roughing bowl gouge sharpened? And those are just, they're ready to go. And I can just quickly switch between them as I'm doing this. You know, I just like that.

Phil Huber (37:32.187) Yeah, that's cool. I can see that.

think what's interesting for me is how I would answer that differently. Like say five years, I would have a very different answer from what I have now. And who knows, five years from now, I might have a different answer again. there is that. The way I would describe it right now for me, I think I would...

I would call it plank woodworking. Is making something from like a single piece or a single chunk of wood. So, you know, like over Christmas I did several shrink pots as a Christmas gift project. We had a tree fall in our neighborhood last fall. So I have three shrink pots from that. you know, so like shrink pots or kitchen utensils.

or sculpted and carved bowls and trays, plates kind of a thing. All of that kind of stuff would be kind of cool for me to do. I like the...

Phil Huber (38:47.259) There's plenty of work that you could do with power tools on it, but being able to engage with the work piece with hand tools is really fun for me. Just feeling how, like using a T-handle auger bit to drill into the end of a branch to create a shrink pot is just a, there's just a fun.

sense of connection that I have in the woodworking with that. think I've added carving to my skill set a little bit over the last few years, and that's a fun element.

in the same way for like, John, that it's just a creative expression and also problem solving, like figure, you know, because when you're working with gouges on a piece of wood, like all of a sudden the grain shifts, you know, it's like, now what do I need to do? Like, come at it from that way or go across the grain to kind of create a trough or a hollow or how can I make this tray look different or like a take a

solid block of wood and create a box with a sliding lid on it so it's just a single piece, you know, where the grain continues to run all the way through it has just a fun, fun element in it. A good amount of challenge and physical exertion and creativity, I think would be would be cool for me. In the past, I would have probably answered it like John doing like tables or

like chests, you know, whether it's like a blanket chest or, you know, like that sugar chest that Chris designed a few years ago. So that, you know, there's all kinds of different ways to look at it. So anyway, I would love to hear what you think as listeners. If the witch from Brave came up to you and gave you the choice, what is your woodworking that you would do for the rest of your life? To be fair,

Phil Huber (40:53.827) I would miss a bunch of other types of woodworking, but that's how I would answer that. To wrap things up, I wanted to share...

along the same lines as a few years ago, I did Christmas presents for family where I did a bunch of kitchen utensils. It was a lot. I think it was I ended up doing like 28 or 30 different types of spoons. So I did a set for myself too. And I had kind of like a spatula looking one and then like a cooking spoon was the idea for it. And back then, I don't remember if it was like

tool limitations or skill limitations or whatever. I wasn't entirely happy with how some of them turned out. I wanted to kind of refine my skills and practice a little bit. So I took two of them, the spatula and then this cooking spoon. I'll put photos on the show notes page. And basically what it was is that they were just a little too chunky, just too thick in places.

Just, that's how you learn. So what I wanted to do, like with the spoon, is to hollow out the bowl a little bit more, thin it out, make it look a little bit more like a spoon. And then the spatula, just the bottom part of it was just way too thick. I made them out of walnut and like I said, wanted to refine those rather than just stick with it with the dried out.

walnut that it was. I put these in a saucepan in some hot water and soaked them for a couple, was about an hour, hour and a half, and then kept them wet overnight. And then this morning worked on them with some crooked knives that I have. It was a project that we did for Woodsmith Chris designed the knives. So they have curved blades on it. And just by soaking the wood for that amount of time,

Phil Huber (42:59.887) the wood fibers were softened and really rather easy to carve. And I was able to quickly refine the shapes into something that I am very, it's a significant improvement, let's put it that way, in the skills. So, last tool that I used was at the last hand works, Jason Lonnen was there.

He's a blacksmith tool maker and he has these little palm gouges, just these wee little guys, kind of like a spoon bent gouge, but with a really short handle on them. And I was able to use that and they're just great tools, exciting to do. not every project you can go back and make it better, but these, these I was able to. So there you go.

Logan Wittmer (43:54.68) Yeah, that is that is one of the things I also really enjoy turning. And that would be in my world of production, bull turning. That would probably be the one spindle thing I would do. I love turning spatulas. I mean, you you can definitely turn spoons and scoops and stuff like that. But I've done several. I have an entire drawer in my kitchen full of wooden spatulas that I've turned.

Phil Huber (44:09.719) yeah.

Logan Wittmer (44:21.518) Um, Richard Graffin, like you cut basically wedges, like wedges of the worst off cuts you've ever seen off the bandsaw. But you're like, yeah, yeah, I turned that into a spatula and you just chuck it in the jaws and go to town with this skew chisel. And it's like, turn it as fast as you can 3000 RPM because you're hitting and missing the whole time. And you just go to town with the skew chisel. love it. That's great. And they're like, they're useful.

Like everything you mentioned, like carving bowls and shrink pots, like it's all useful stuff. It's not like it is, I'm not saying things we build in woodworking aren't useful. It's just, are utilitarian everyday things like shrink pot, perfect little sugar container for the counter or coffee bean container. You know what I mean? Like everyday items, love it.

Phil Huber (45:11.087) Yeah. All right. There you go. That wraps up another episode of the ShopNotes podcast. We want to hear from you. You can send us an email, woodsmith at woodsmith.com or subscribe on the Shop Notes podcast YouTube channel. Like, subscribe, ring the bell, all the little things. And wherever you listen to the podcast, especially if you're driving, you're listening to it from some platform, please rate and review the podcast there. That helps.

us to get the word out to more people with more comments where we could talk about more things and make even more subtle digs at Shopsmith.

We'll see you next week, everybody. Bye.