Selecting and using Japanese Saws

When it comes to precise cuts and fine joinery, these razor-sharp saws can help you get the job done without breaking the bank.

For most woodworking tasks, I rely on power tools to do the heavy work. But when you only need to make a few quick cuts, setting up a table saw is more work than just cutting the part with a hand saw.

The trouble is, to make hand-tool work possible, you need to start with good-quality tools. And if you’ve shopped around recently for a good Western dovetail or tenon saw you’ll know that $100 doesn’t go very far. The good news is that there’s a great alternative. Japanese saws are readily available, and a good-quality saw will only set you back about $40.

WHAT’S THE DIFFERENCE?

You can tell just by looking that the Japanese and Western approaches to saw designs are, well, from opposite sides of the world. The first thing you’ll notice when you pick up a Japanese saw is how light it feels in your hand. That’s because the blade is so much thinner than its Western counterpart. On top of that, rather than a carved hard-wood handle a Japanese saw has a long, straight handle. This handle is made from a very light wood, usually Japanese cypress or cedar (not bamboo as is commonly thought), and wrapped in cane.

TEETH.

The next thing you’ll probably discover are the razor sharp teeth. Even on inexpensive mod-els, the teeth of a Japanese saw are extremely sharp. And when you take a closer look, you’ll see that they’re shaped very differently than those on a Western saw.

The drawings at the bottom of the page shows the differences between Western and Japanese crosscut teeth. Japanese crosscut teeth have three beveled edges rather than two. The third bevel near the tip of the tooth is ground at a very steep angle, making each tooth like the blade of a knife.

The rip teeth on a Japanese saw are very similar to Western teeth. The big difference here is, Japanese saws are designed specifically for either hard or softwood. Softwood teeth have a steeper cutting angle.

But the biggest difference in the Japanese teeth is that their cutting edge is pointed toward the handle, meaning the saw will cut on the pull stroke rather than the push stroke like a Western saw.

WHY A PULL CUT?

It may seem strange to pull a saw, but if you stop and think about it, it really makes a lot of sense. The thin metal used for saw blades works much better when the blade is in tension (as in a pull stroke) rather than compression (on a push stroke). This is why the Japanese blades can be so made much thinner than Western blades.

You may also find it easier to guide and control a cut by pulling rather than pushing a blade. Once you’ve learned some basic tech-niques, you’ll find the combination of super-sharp teeth, light weight, and pull-stroke cutting will have you making more accurate hand saw cuts than ever before.

QUALITY.

But that combination of features only works if the quality of the steel and manufacturing are pretty high. And the tradition of high quality tool making goes back hundreds of years in Japan. That tradition set the bar very high for even the factory-made tools commonly available in the U.S. today.

REPLACEABLE BLADES.

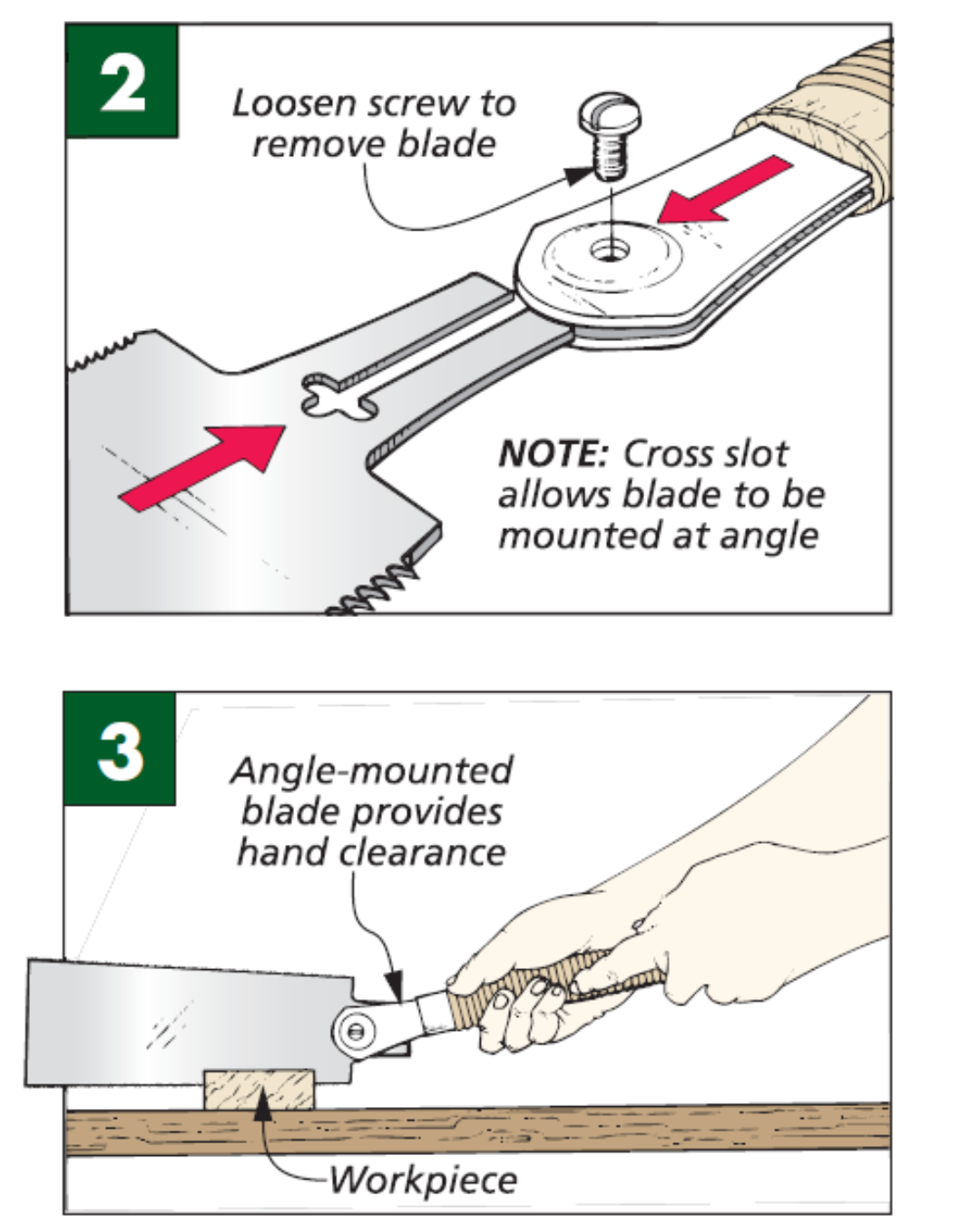

One of the nice features of today’s factory-made saws is the replaceable blade. You’ll appreciate this as you start to “unlearn” the push-stroke habit. A damaged or bent blade can be easily removed and replaced with a new one. On some saws, you can even adjust the blade angle, as shown Figures 2 and 3 below.

SAW TYPES.

There are many different types of Japanese saws. The four saws you see in the margin at right are the ones I use most often for joinery in my shop. We’ll take a look at each of these saws individually on the following pages.

Dozuki

If you’re ready to give Japanese saws a try, then a dozuki is the place to start. The stiff supporting spine over the blade (like that on a Western backsaw) makes it easier to cut with and a little more forgiving than some of the other saws.

Most dozuki have crosscut teeth since cutting tenon shoulders is the traditional use for a dozuki. (In fact, the word dozuki means shoulder.) But you can still use this saw for fine rip cuts like cutting dovetails.

DOZUKI CUTTING TECHNIQUE.

To get started with a dozuki, you’ll first need to lay out the cut. Then, begin the cut with the heel of the saw on the waste side of the line. Hold your thumb against the side of the blade to guide the cut. Now pull back slowly, without applying any downward pressure on the blade. Just let the teeth pull into the cut naturally.

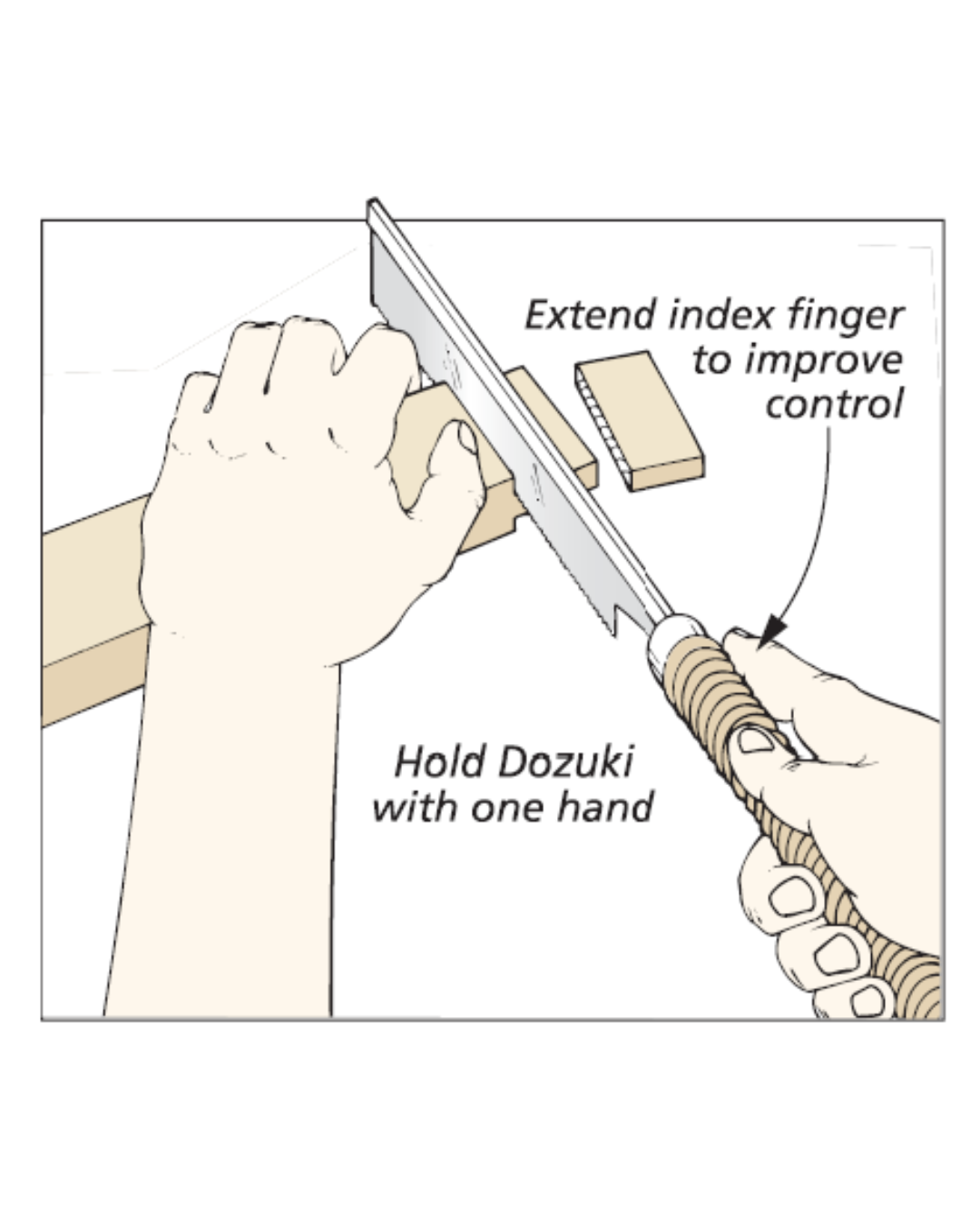

You may want to try pointing your index finger down the back or side of the saw to help track a straight line. To cut the shoulders for a tenon, see the box below. You’ll find the saw leaves a very smooth cut.

|

|

Ryoba

Ryoba means “double,” referring to the two cutting edges. (A single-edge saw is called a kataba.) A ryoba typically has rip teeth on one edge and crosscut teeth on the other. Ryoba saws are available in several sizes. The larger saws are used for construction, and the smaller ones for cabinetmaking.

The teeth on a ryoba are sized according to blade length — the smaller the saw, the more teeth per inch. For most general woodworking needs, look for a saw with a 7" to 9" blade. The combination of crosscut and rip teeth give the ryoba a versatility you’ll appreciate. Once you get used to using one, you’ll find yourself reaching for it often. The downside of cutting with a ryoba is that the teeth on the opposite edge can leave scratch marks when they enter the kerf of a deep cut.

CUTTING WITH A RYOBA.

The larger ryoba saws are usually used for cutting the joinery for timber-framed construction and are designed for two-handed use. Even with the smaller saws, you’ll find that a two-handed grip can be useful at times. The “golf-style” grip shown in the illustration at left can save your arms some fatigue if you’re making a lot of long cuts. With this grip, as with the dozuki, pointing your index fi nger forward helps keep the blade running true.

The larger ryoba saws are usually used for cutting the joinery for timber-framed construction and are designed for two-handed use. Even with the smaller saws, you’ll find that a two-handed grip can be useful at times. The “golf-style” grip shown in the illustration at left can save your arms some fatigue if you’re making a lot of long cuts. With this grip, as with the dozuki, pointing your index fi nger forward helps keep the blade running true.

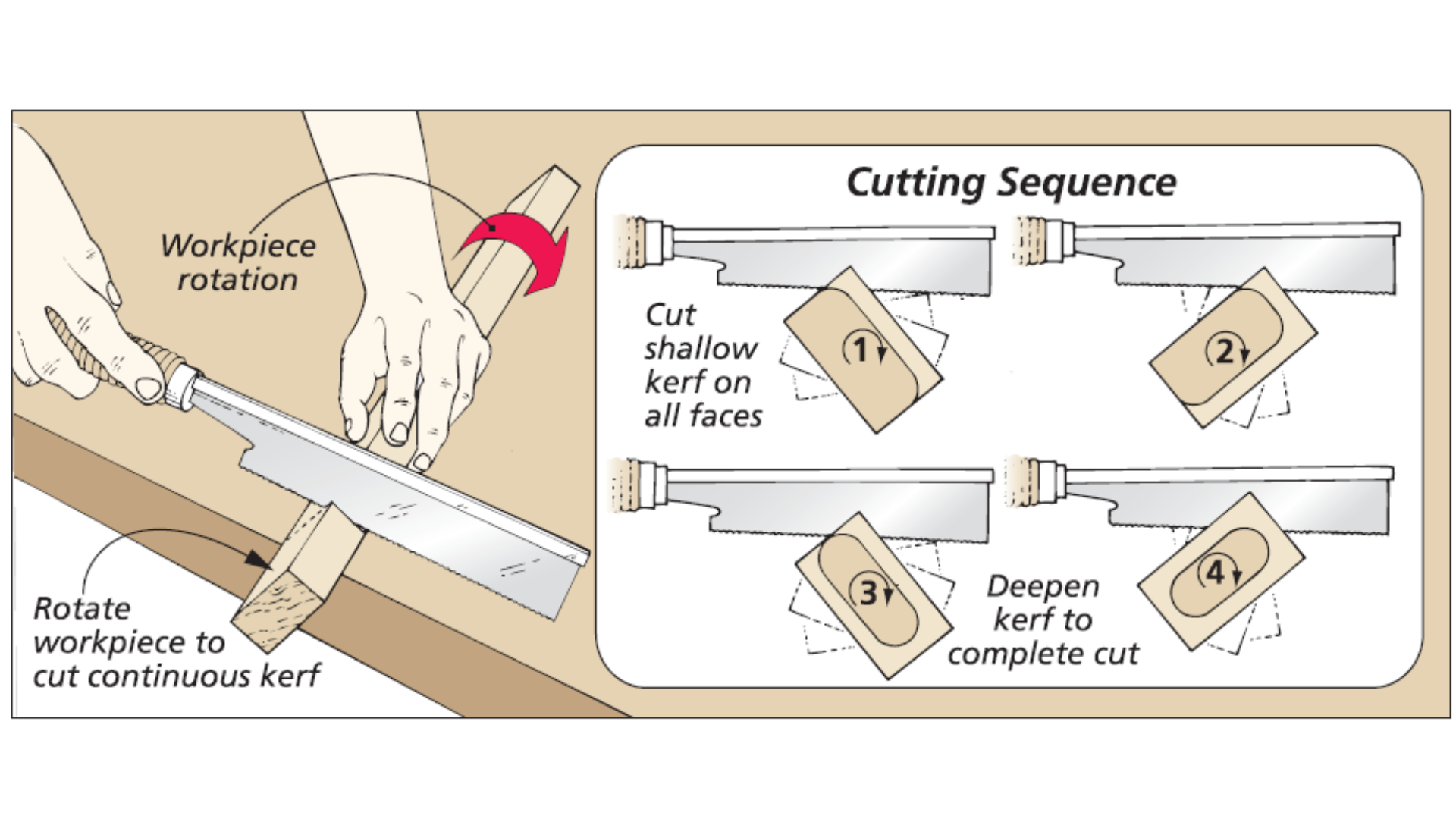

But using the saw with one hand usually works fine for joinery and other small work. In this case, you can hold the saw like a dozuki. The easiest way to get started is by slowly pulling the heel of the saw across the cut line. Then you can gradually lengthen the stroke as the cut deepens. The ryoba blade is thick enough to resist buckling as you push it back into the cut, but it’s still a good idea to take it slow.

Kugihiki

Even if you don’t do much handwork, you’ll probably want to check out a kugihiki. It makes short work of flush cutting a dowel, or a through tenon.

Kugihiki means “to cut nails,” referring to the bamboo spikes used in Japanese temple construction. But there are plenty of applications in Western-style woodworking. The great thing about this saw is that the crosscut teeth are not set (each alternating tooth bent outward). That allows you to lay the blade flat on a workpiece and make a cut without marring the surface.

USING THE KUGIHIKI.

Because the kugihiki blade is extremely thin (about .007" at the tip), it’s probably the toughest of the Japanese saws to use without bending the blade on the return (push-stroke) of a cut. The key here is to take it slow until you’re comfortable using it.

Because the kugihiki blade is extremely thin (about .007" at the tip), it’s probably the toughest of the Japanese saws to use without bending the blade on the return (push-stroke) of a cut. The key here is to take it slow until you’re comfortable using it.

You may be tempted to hold the thin blade flat with your other hand, but that only pushes the teeth into the surface. Instead, flex the blade (as in the photo), and it will automatically remain flat. Then just pull through the cut and you’ll be pleased with the results.

Azebiki

The azebiki is a double-edged saw with curved rip and crosscut blades. The azebiki is traditionally used for cutting mortises, grooves, and even sliding dovetail joints. The curve of the blade allows you to start a cut in the middle of a board. All you need to do is scribe a layout line and you’re ready to cut. The curved blades also help clear out the sawdust from the kerf of the cut.

|

| You might not use the azebiki, every day, but it’s great for those occasions when the task demands it. |

CUTTING TECHNIQUES.

To cut a mortise in the middle of the workpiece, start by making a series of light cuts on the layout line. Once you’ve established the kerf, apply a little more pressure using a rocking motion with your arm to deepen the cut. You’ll soon cut through the board. Clamping a straight board next to the line helps keep the cut on the mark and the saw vertical.

To cut a mortise in the middle of the workpiece, start by making a series of light cuts on the layout line. Once you’ve established the kerf, apply a little more pressure using a rocking motion with your arm to deepen the cut. You’ll soon cut through the board. Clamping a straight board next to the line helps keep the cut on the mark and the saw vertical.

A Modern Revision

Japanese saw-making techniques and traditions go back hundreds of years, but that doesn’t mean there hasn’t been a continual adaptation of the various designs. For instance, the saw in the photo below has a traditional dozuki blade. But instead of a spine, this saw has a steel bar fit into the handle. The bar holds two wing nuts that allow the position of the slotted blade to be adjusted. Sliding the blade up toward the bar limits the depth of cut. This makes it ideal for cutting dovetails.

Japanese saw-making techniques and traditions go back hundreds of years, but that doesn’t mean there hasn’t been a continual adaptation of the various designs. For instance, the saw in the photo below has a traditional dozuki blade. But instead of a spine, this saw has a steel bar fit into the handle. The bar holds two wing nuts that allow the position of the slotted blade to be adjusted. Sliding the blade up toward the bar limits the depth of cut. This makes it ideal for cutting dovetails.

Blade parts: Wing nut adjustment, Scale on end of blade aids in setting depth of cut, Long slot allows wide range of cutting depth.

Blade parts: Wing nut adjustment, Scale on end of blade aids in setting depth of cut, Long slot allows wide range of cutting depth.