Within woodworking, there are—as the macabre saying goes—plenty of ways to skin a cat. In this issue’s Great Gear, we’ll be looking at a few products that offer alternatives to your usual ways of working. We’ll start in the world of CNC work, followed by options for sanding and applying finish, and I think you’ll find these tools merit taking a look at, or even a place in your shop.

CNC WORKHOLDING KIT

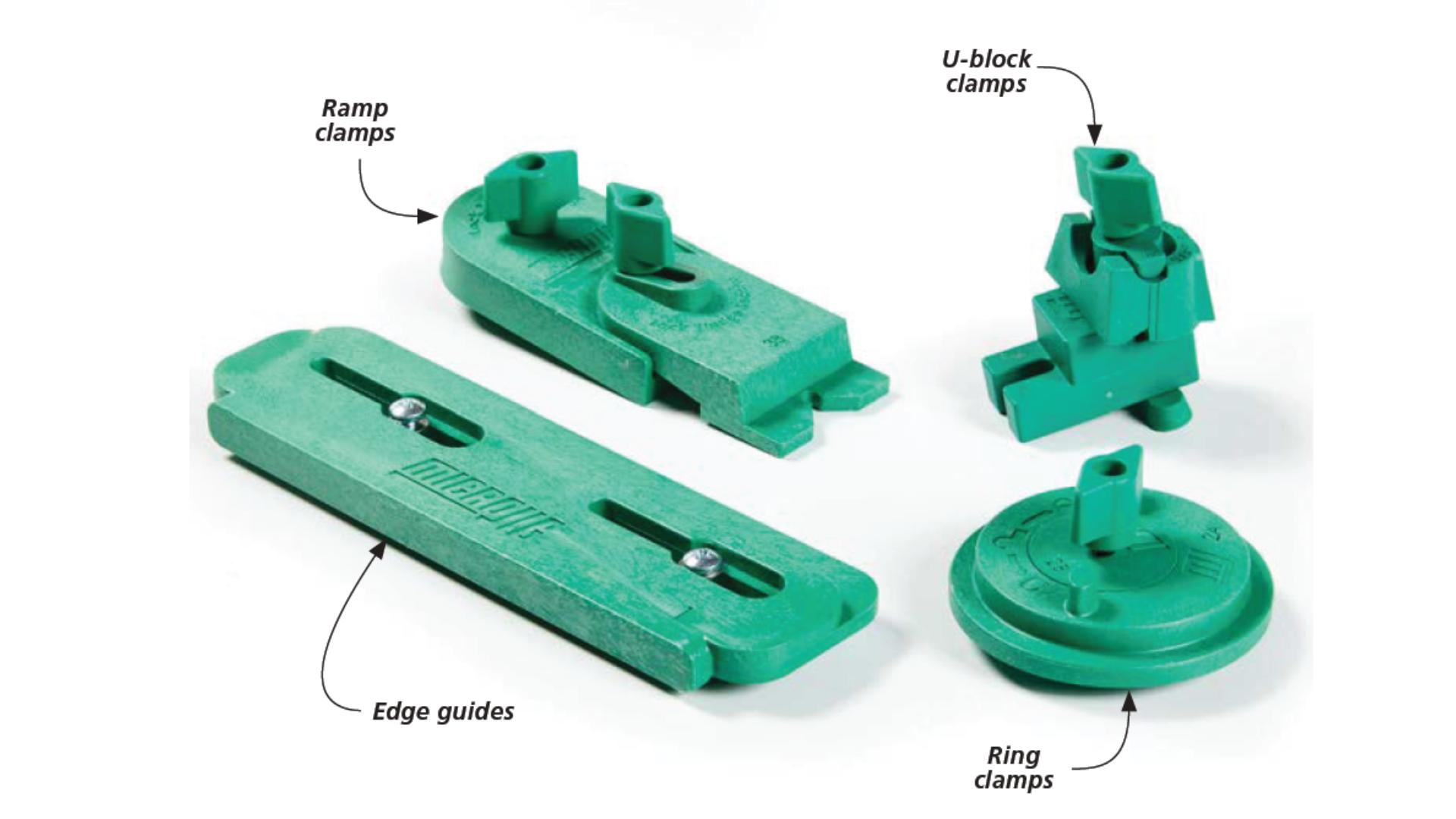

The CNC Workholding Kit is from MicroJig’s MatchFit line of products, which all revolve around the use of dovetail tracks. In past Great Gears, we’ve looked at a few options for clamps and hold-downs, but in this issue, we’re checking out a series of holders designed for CNC projects.

EDGE GUIDES.

|

| The edge guides are designed to work in conjunction with the ring and ramp clamps. The low profile provides clearance for cuts along the edge. |

There are four kinds of holders here, and we’ll start with the edge guides (shown in the left photo above). These parts have cleats that hold them straight to the edge of the spoilboard. They’re designed to brace the workpiece while using the ramp or ring clamps.

RAMP CLAMPS.

|

| The rear knob locks the clamp assembly in place. Meanwhile, tightening the front knob wedges the clamp against the workpiece, holding it in place. |

For most flat-edged workpieces, the ramp clamps will be your go-tos. These consist of two ramped halves that each screw down. The rear knob tightens down first to lock the clamp in place. Tightening the front knob causes the ramped parts to slide down, pressing into the workpiece. This function is great for working with multiple pieces, as the clamp can stay locked in place while loosening the front and switching between pieces.

RING CLAMPS.

|

| Twisting the ring on these clamps cams against the workpiece to lock it in place. Like the ramp clamps, these can be left in position when exchanging parts. |

The ring clamps are designed to be used with curved workpieces, such as the corbel shown in the lower left photo. These have a similar function to the ramp clamps, though a different execution. After locating them, the central knob locks the base in place. The base is ellipical, allowing the ring around it to cam into the workpiece as it rotates in order to hold it in place.

U-BLOCK CLAMPS.

|

| The U-block clamps are sturdy holders for more demanding cuts. The clamps themselves pivot off of the U-blocks, applying pressure to the corners to prevent the workpiece from moving laterally or vertically. |

The previous three holders apply pressure to the workpiece from the side, which is fine for operations where the force is mostly lateral. However, when the force is being applied mostly upward — as it would be when using a spiral upcut bit — a holder that clamps from above as well is needed. That’s where the U-block clamps come in.

You can see how these clamps work in the right photo below. The clamp itself pivots off the U-block, applying pressure to the corners of the workpiece. The four of these that come with the kit are more than sufficient for nearly all CNC projects.

These holders are a welcome addition to my CNC arsenal. Of course, they do need dovetail tracks to work as intended, but MicroJig also offers a solution for that, which you’ll see soon.