Knock-down construction is certainly not a modern invention. Furniture and other utilitarian items designed to be disassembled have been built for centuries. As it still is today, this was often simply a matter of making large pieces easier to move from place to place.

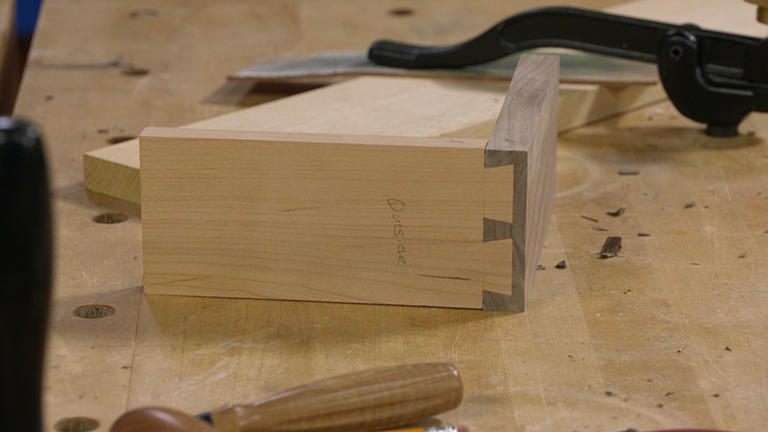

Traditionally, one of the common methods of building this type of practicality into a project was to incorporate loose-wedge mortise and tenon joints. The basic concept is pretty easy to understand. Rather than glue or pin the tenon into the mortise, the tenon is temporarily locked in place by inserting a large, removable wedge. You simply tap out the wedge, and the joint can easily be taken apart.

You’ll find that the connection formed by a loose-wedge mortise and tenon can be surprisingly sturdy and durable. It also offers the advantage of accommodating seasonal wood movement — a tap on the wedge tightens the joint. But possibly the best selling point is the interesting, almost puzzlelike, appearance of these joints. It’s guaranteed to create curiosity and draw attention.

The most recognizable take on this joint is the basic tusk tenon. It’s often seen as a design element of Craftsman-style furniture. However, there are a number of other interesting variations of this type of joint. And they’re just as useful today as in the past. To get you thinking, I’ll describe a few examples of different loose-wedge mortise and tenon joints.

BASIC TUSK TENON

As I mentioned, the drawings illustrates a basic tusk tenon joint. You start the joint by making a through mortise and tenon. The tenon (or tusk) is made extra-long to accommodate a beveled wedge mortise. This mortise is positioned so that when the wedge is inserted, the tenon shoulders are pulled snugly against the mortised piece.

There are a handful of fine points that I should mention. The wedge is usually oriented vertically to prevent it from working loose. And for maximum “draw,” the outer face of the wedge and wedge mortise should be beveled to a shallow angle of about 5°. The inner face of the wedge mortise extends slightly into the main mortise. This ensures that the joint will close up when the wedge is driven home.

The pressure exerted by the wedge on the outer face of the wedge mortise is how the work gets done. This means that you want the angle of the wedge and the mortise to be a perfect match. And to avoid splitting, be sure to leave adequate material beyond the wedge mortise at the end of the tenon — a minimum of 1 ⁄ 2 ".

DOUBLE-WEDGE TUSK TENON

A double-wedged tusk tenon works on the same principle as the basic tusk tenon, but the makeup of the joint is slightly different. As shown in the drawing below, this joint uses two wedges inserted into the wedge mortise from opposite sides to lock the tenon in place.

The difference is that the use of two opposing wedges with identical bevels means that the outer face of the wedge mortise can be left square. And for obvious practical reasons, a double-wedged tusk tenon works best if the wedges are oriented horizontally.

FORKED-WEDGE TUSK TENON

At first glance, a forked-wedge tusk tenon (shown in the drawing below) may seem more fantasy than useful woodworking joint. But once you put it to the test, you’ll find that although it’s a bit of a challenge to make, it works like a charm and looks great.

The twist is that the tusk tenon is not mortised for a wedge. Instead, a tapered wedge notch is cut along both cheeks of the tenon. A “forked” wedge fits over the tenon and bears against the tapered shoulders of the wedge notches, locking the pieces rigidly together. A big advantage is that maximum wedging force can be applied with virtually no chance of the tenon splitting.

The criteria for positioning the wedge notches and the bevel angle is the same as for a basic tusk tenon. The notches should be deep enough to provide good bearing surface for the wedge — at least 1 ⁄ 8 ".

The slot in the wedge is sized for an easy fit over the tenon and made long enough so that it doesn’t bottom out when inserted.

DOVETAILED AND WEDGED TENON

A dovetailed and wedged tenon joint has a bit of mystery to it. When assembled, it’s not completely obvious how it works. But when you look inside the joint, as in detail ‘a’ in the right drawing below, it makes perfect sense.

Like the others, the joint is based around a through mortise and tenon. But as you can see, the mortise is cut with ends that flare outward, like a dovetail socket. The lower edge of the tenon is cut to match the angle of the mortise ends. When a wedge is inserted along the upper edge of the tenon, the downward force pulls the tenon deeper into the mortise and locks the joint very securely.

When making the joint, the narrow end of the mortise has to be at least as wide as the widest part of the tenon. And a fairly steep angle of 10° or 12° will help maximize the wedging action.

The list of suitable uses for these joints is extensive. A couple of obvious examples are trestle tables and workbenches. But these joints can also be incorporated into casework, shelving, or bed frames.