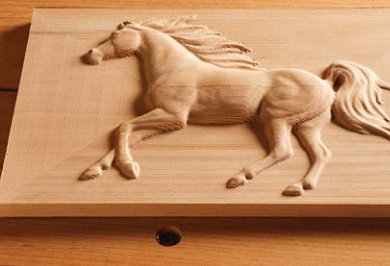

Creating stunning carvings in wood or acrylic plastic has never been easier than when using your CNC router. Think of all the creative possibilities for carvings: door panels, box lids, frieze boards, emblems, awards, artwork, signs or having your signature carved into the back of a project. Not only can the CNC router add beauty and interest to your work, but it’s a blast to watch as the machine dances along the workpiece methodically and precisely, revealing a beautiful carving.

So how do we start creating carvings with our CNC router? First, we need a digital image. You can create your own or find one online. To create a 3- dimensional image suitable for a carving requires specialized software. Vectric Aspire, Rhino and 3D Systems Geomagic Freeform are some of many examples of software capable of creating 3d models suitable for carving. A simpler solution for those of us who want to incorporate CNC carvings without mastering the software is to use 3d clip art available online. There is an amazing variety of 3d clip art ready for you to download, so plan on spending several hours online being awed by all the choices.

So how do we start creating carvings with our CNC router? First, we need a digital image. You can create your own or find one online. To create a 3- dimensional image suitable for a carving requires specialized software. Vectric Aspire, Rhino and 3D Systems Geomagic Freeform are some of many examples of software capable of creating 3d models suitable for carving. A simpler solution for those of us who want to incorporate CNC carvings without mastering the software is to use 3d clip art available online. There is an amazing variety of 3d clip art ready for you to download, so plan on spending several hours online being awed by all the choices.

There are many sources to purchase CNC router ready clip art. Here are a few:

• www.designandmake.com

• www.3dcncmodels.com

• www.sl-model.com

• www.3dwave.org

Web searches may reveal free clip art, provided it suits your needs. Just make sure that the file type is compatible with your software.

Creating cut files for carving requires CAM software capable of working with a 3d digital image. If you have CAM software limited to 2d projects you may want to consider using clip art from www.designandmake.com which offers free downloadable software for use with their 3d images. Once you have found a 3d image file and have downloaded it into your CAM program, the model can be scaled larger or smaller, deeper or shallower, narrower or wider, taller or shorter to fit your application.

CNC router carving is typically of the high relief style. The carved area can be set below the surrounding surface in a pocket or dish, or it can be cut to sit proud of the surrounding surface. Another option is to create carvings cut out from their parent stock, which can then be affixed to panels, architectural elements and so forth.

The final step before cutting is setting the tooling parameters and generating the instructions (G-code) for your CNC router.

Milling a 3D carving is typically done in two stages. The first is a roughing cut in which the bulk of the material is removed, leaving a recognizable but low-resolution image. A straight spiral upcut bit is the right choice for this operation because it efficiently cuts and clears away debris.

Milling a 3D carving is typically done in two stages. The first is a roughing cut in which the bulk of the material is removed, leaving a recognizable but low-resolution image. A straight spiral upcut bit is the right choice for this operation because it efficiently cuts and clears away debris.

The second step is a finishing cut in which a ball nosed bit is used because of its ability to make smooth, precise cuts. Depending on the size and detail level of the carving, combinations such as a ¼” roughing bit and a 1/8” ball nose finishing bit or ¼” roughing bit and 1/16” tapered ball nose finishing bit are common. For smaller work, a 1/8” roughing bit may be best with a 1/32” ball nosed bit for the final cut.

The second step is a finishing cut in which a ball nosed bit is used because of its ability to make smooth, precise cuts. Depending on the size and detail level of the carving, combinations such as a ¼” roughing bit and a 1/8” ball nose finishing bit or ¼” roughing bit and 1/16” tapered ball nose finishing bit are common. For smaller work, a 1/8” roughing bit may be best with a 1/32” ball nosed bit for the final cut.

There’s more here than just selecting a bit combination. The difference between a stellar cut and a so-so cut comes down to managing the stepover and lateral velocity when setting up the cutting files. Stepover is the sideways distance the bit moves once it completes a cutting circuit. The larger the stepover the faster the cutting process, but with less resolution. A smaller step means a longer process time but higher resolution. Generally, the roughing cut can be managed for speed using the maximum stepover and lateral velocity. The finishing cut, however, requires a bit of judgement to balance the level of detail wanted and production time needed to complete the project. A piece of advice: when you change from the roughing bit to the finishing bit do remember to re-zero the z-axis height!

Acrylic plastic and wood both require the same steps, however, you will achieve the best results in acrylic by using bits specifically made to cut plastic.

Using a CNC router allows you to easily create carvings with an incredible level of detail. There's a vast array of possibilities, and once you've gotten down the right set-up, you're only limited by what images you can find or create. Requiring only a few bits and a little know-how, CNC router carvings can be a fantastic addition to your next project.

Special Offer