Joinery is at the heart of any successful woodworking project. Your CNC router offers many options of different types of joints, often resembling traditional joinery that you are probably already familiar with. The challenge of CNC joinery is that the router bit cannot cut a sharp 90° corner – it will always leave a radius equal to that of the bit. Additionally, CNC routers can only cut from the top of the workpiece, or the bottom if you index and flip the part, but not from the sides, ends or at an angle. However with a few tricks and a little thought you will find a wide range of ways to connect parts that are strong, attractive and easy to make. Some joints can be cut exclusively on your CNC router while some are made with a little help from a palm router, here are a few example to help get you started:

Joints cut only with a CNC router:

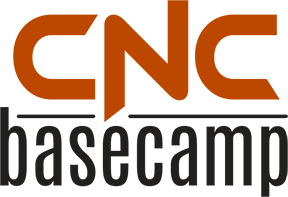

• Tongue and groove - an easy to make joint with many applications. In order to accurately size the tongue, it is best to zero the Z-axis off of the spoilboard and not the top of the material.

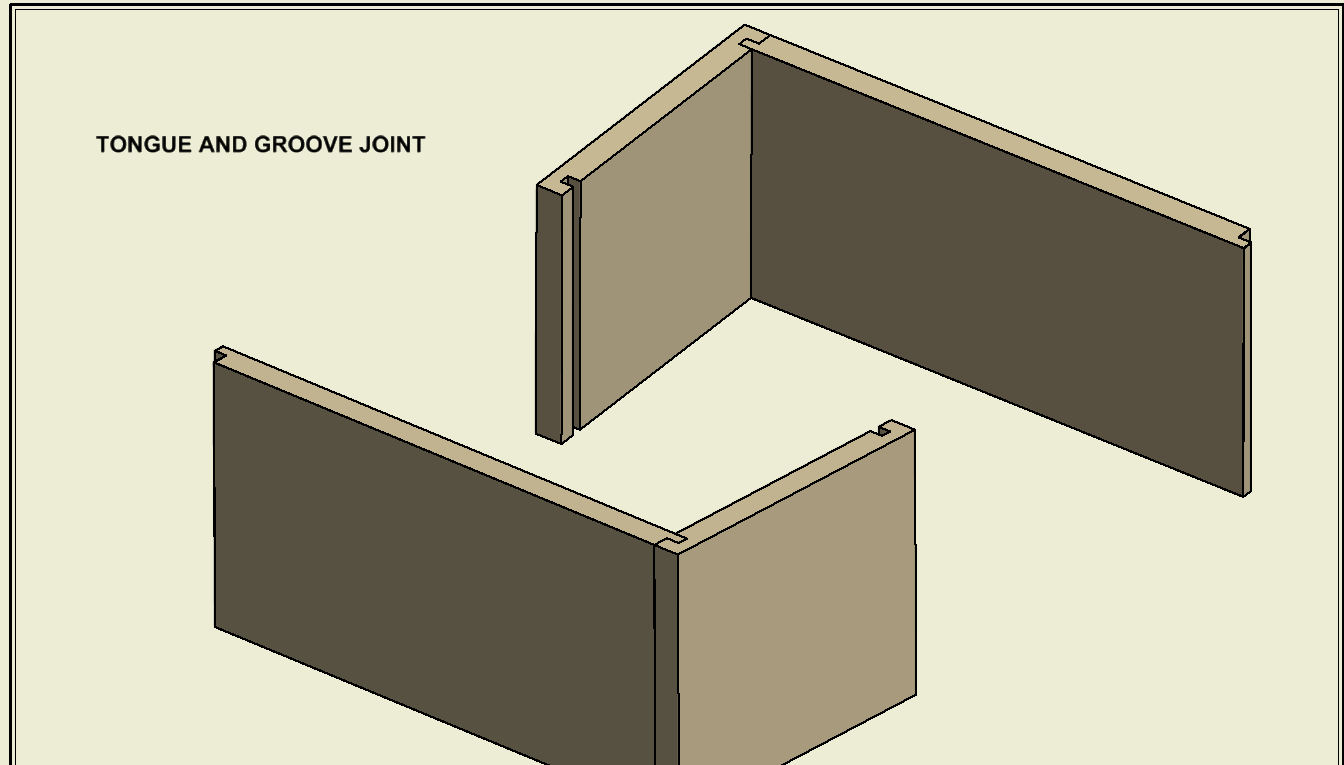

• Box joint with dogbone - strong and versatile, the box joint is a workhorse in CNC joinery. The dogbone provides clearance in the corners, however the clearance cut is visible from both the outside and inside of the joint, so it’s a busy look.

• Box joint with dogbone - strong and versatile, the box joint is a workhorse in CNC joinery. The dogbone provides clearance in the corners, however the clearance cut is visible from both the outside and inside of the joint, so it’s a busy look.

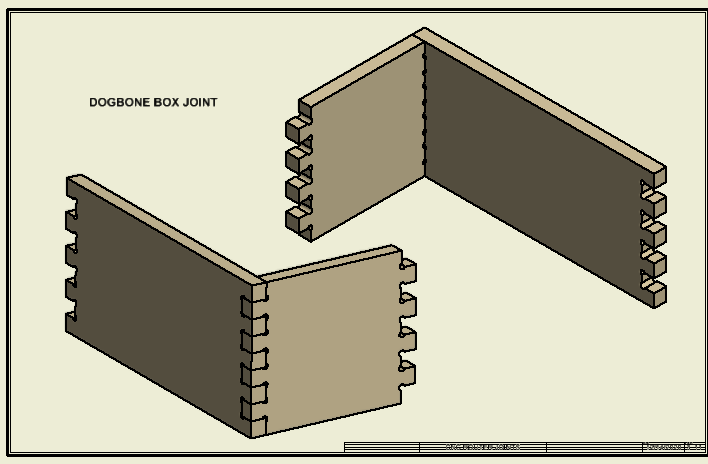

• Box joint with t-bone - a variation of the box joint with dogbone, the t-bone looks about the same from the outside but offers a clean interior corner.

• Box joint with t-bone - a variation of the box joint with dogbone, the t-bone looks about the same from the outside but offers a clean interior corner.

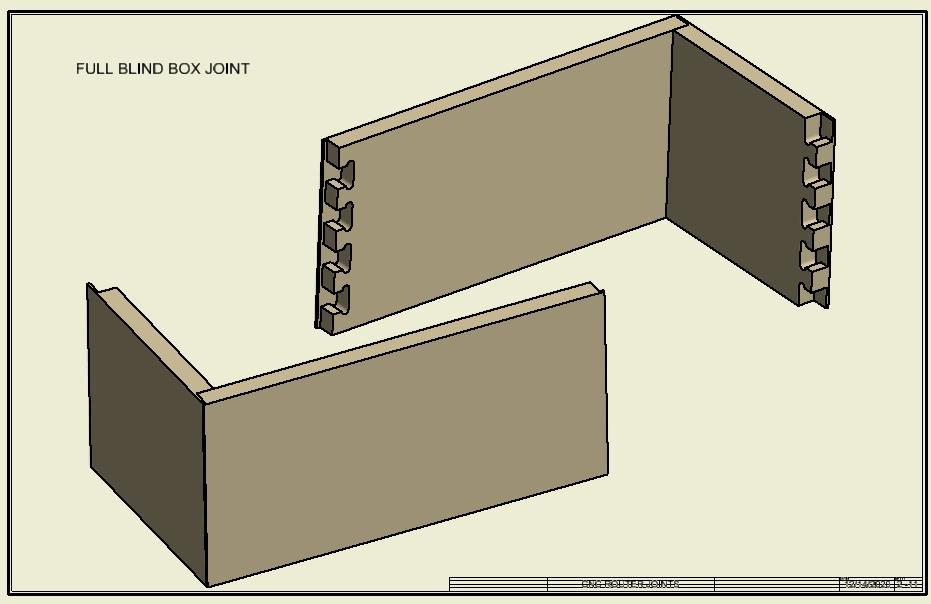

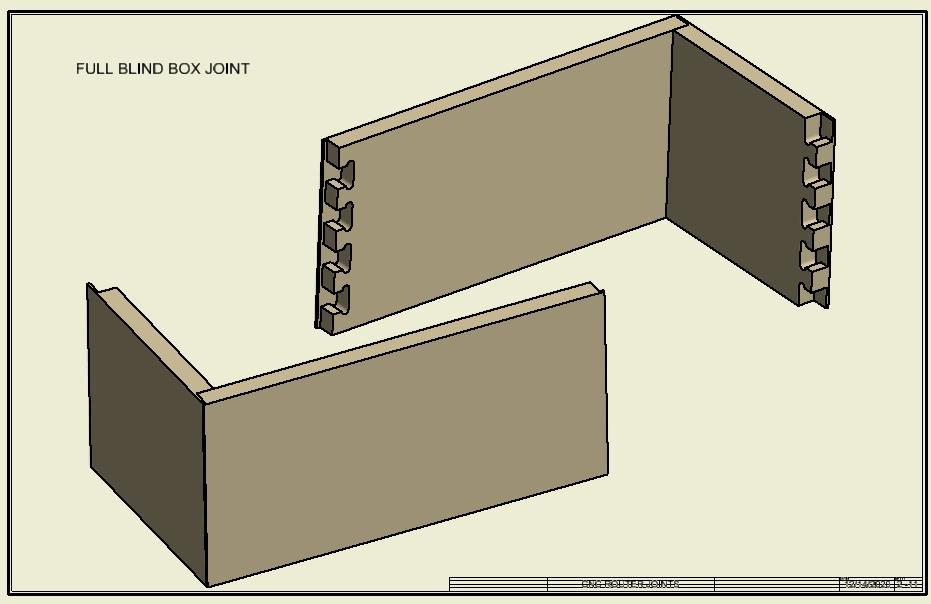

• Blind box joint - clean looking and super strong, the blind box joint hides the clearance cuts and the box joint fingers.

• Blind box joint - clean looking and super strong, the blind box joint hides the clearance cuts and the box joint fingers.

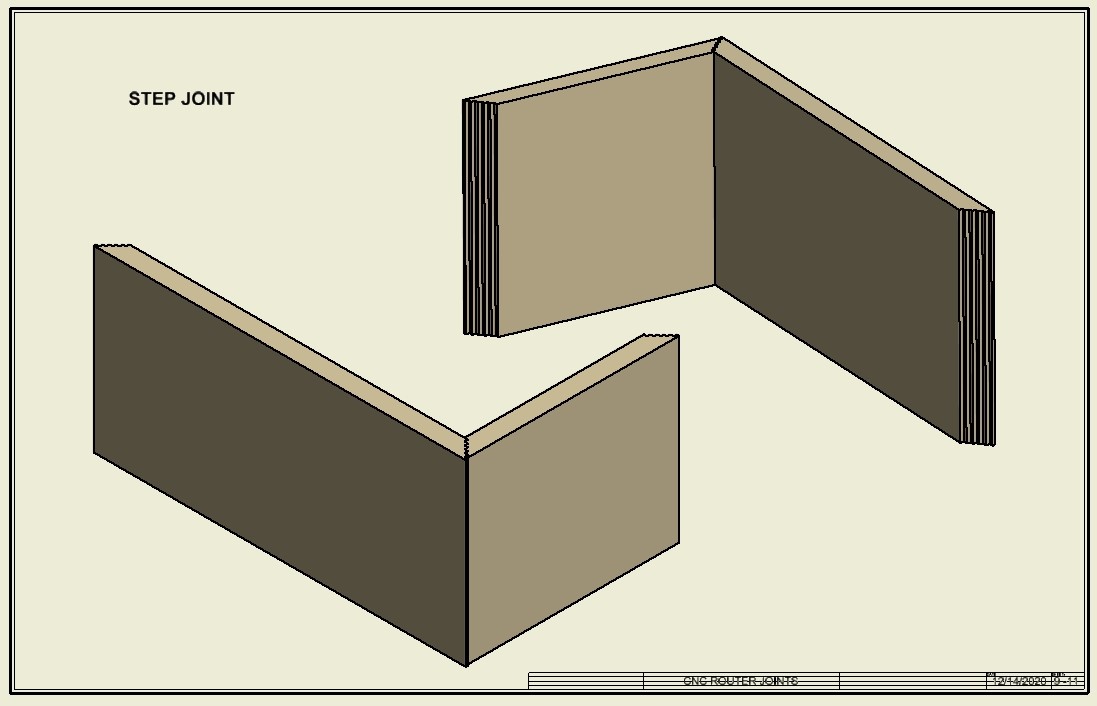

• Step joint - a simple joint with 35% more glue area than a simple miter. The steps make for a positive registration during glueups.

• Step joint - a simple joint with 35% more glue area than a simple miter. The steps make for a positive registration during glueups.

• Blind mortice and tenon a great drawer making joint, the blind mortice and tenon offers strength and simplicity.

• Blind mortice and tenon a great drawer making joint, the blind mortice and tenon offers strength and simplicity.

Joints using a CNC router teamed up with a handheld router:

Using a router with a solid pilot roundover bit opens many new possibilities for joinery with a CNC router. The small pilot (usually about 3/32”) can get into tight corners, rounding over edges so that they fit the radiused corners left by the CNC’s router bit.

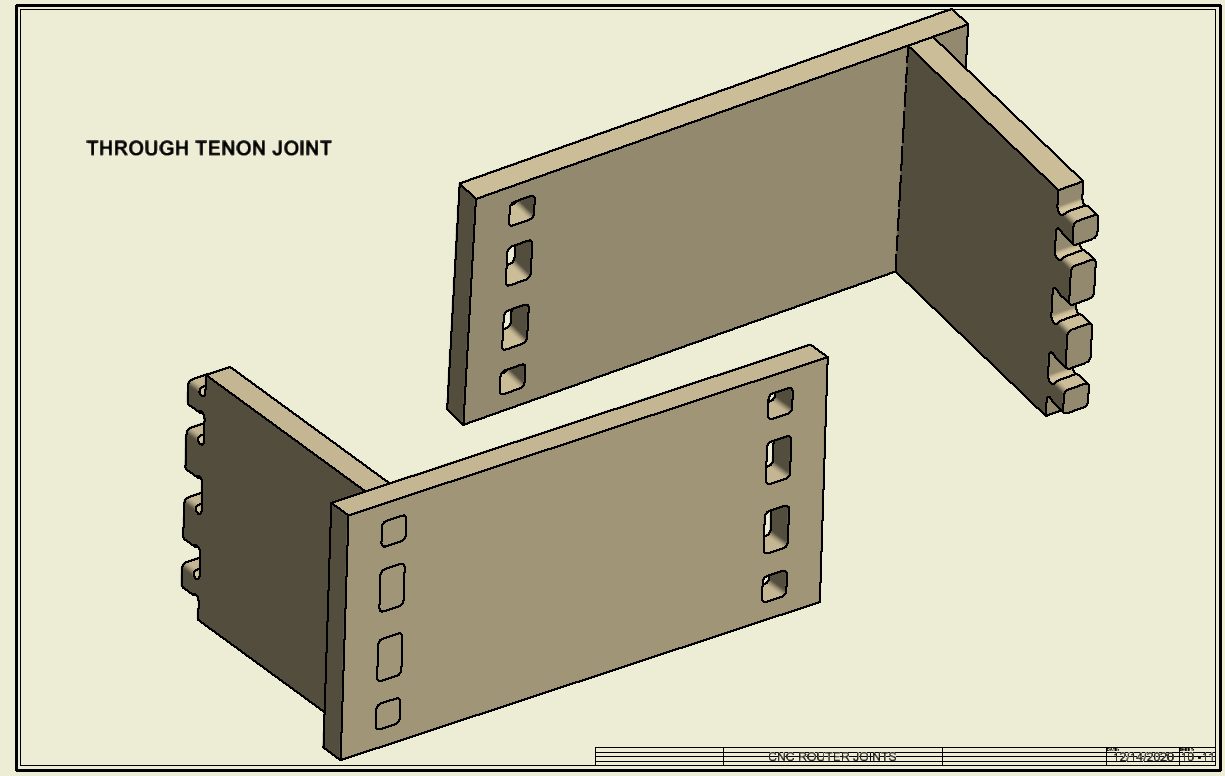

• Through mortice and tenon - a simple joint with visual appeal.

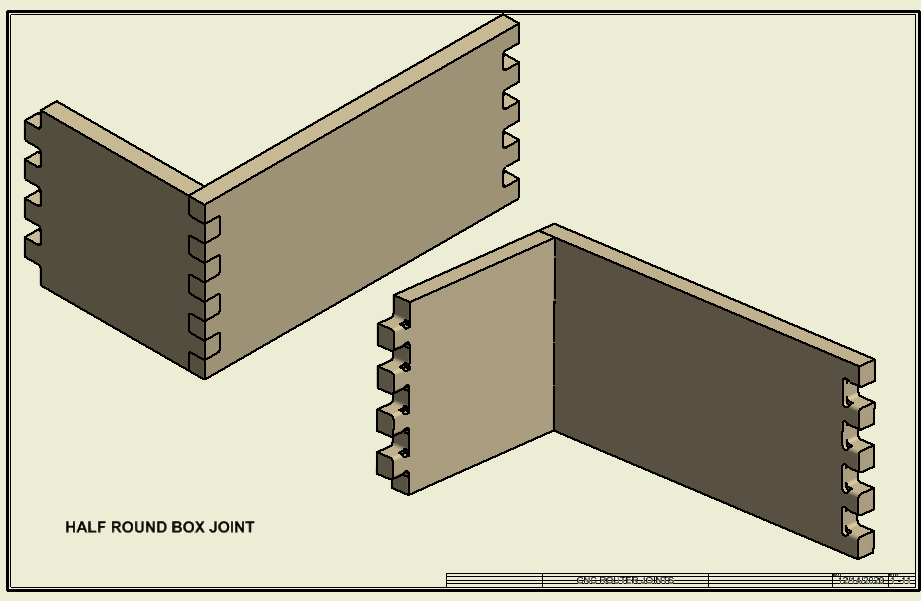

• Box joint ½ round - a version of the box joint in which the inside edges are rounded over for a good fitting and attractive joint.

• Box joint ½ round - a version of the box joint in which the inside edges are rounded over for a good fitting and attractive joint.

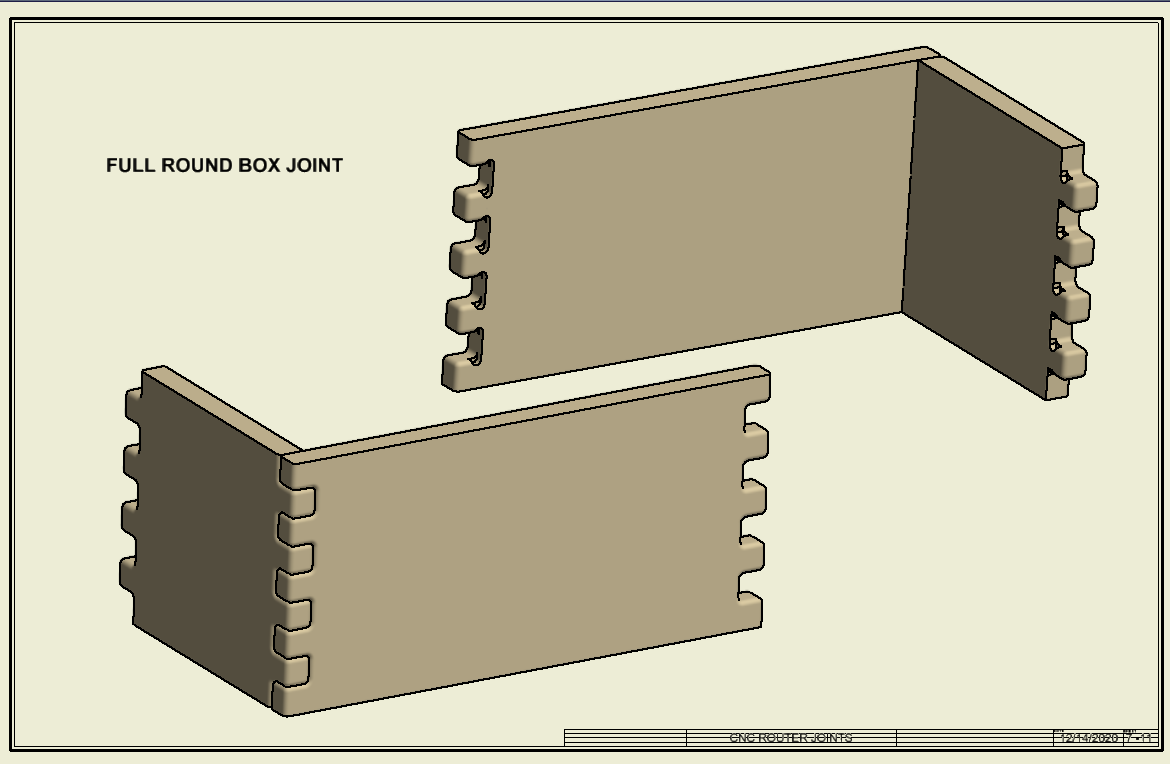

• Box joint full round - this box joint variety has interesting visual texture that turns a simple corner into a design element.

• Box joint full round - this box joint variety has interesting visual texture that turns a simple corner into a design element.

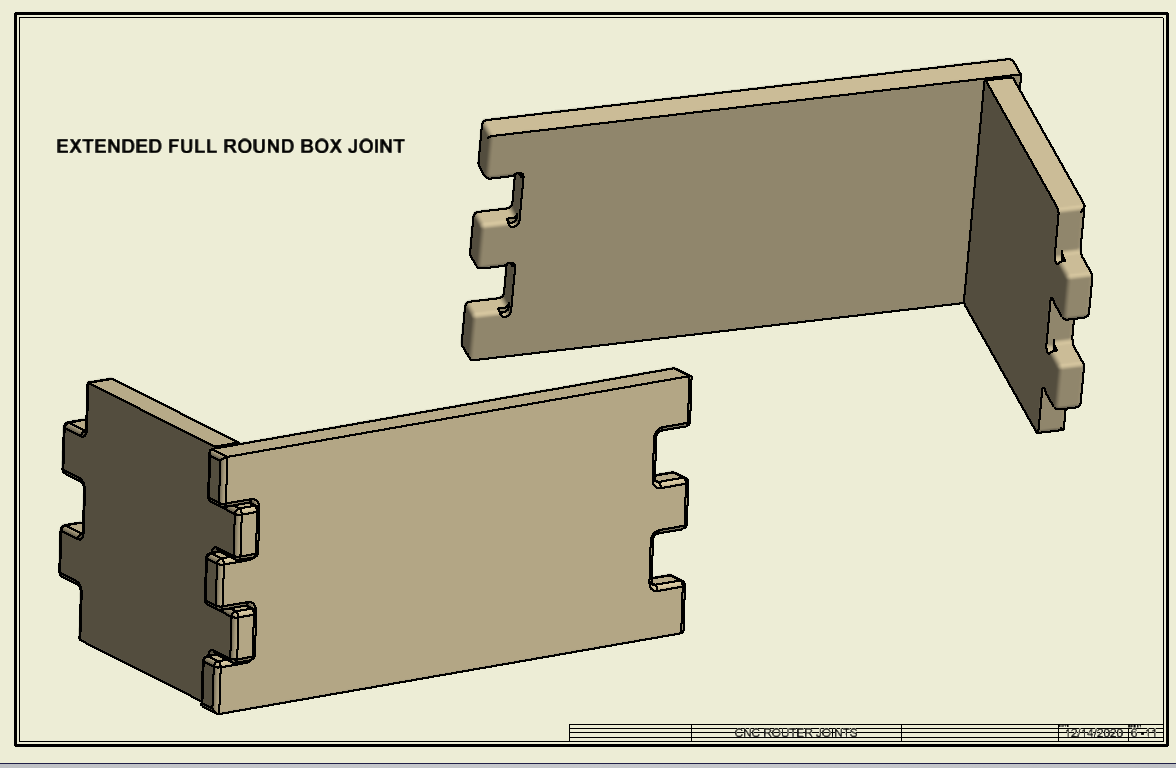

• Box joint extended half or full round - another variation which lets the fingers of the joint run long.

• Box joint extended half or full round - another variation which lets the fingers of the joint run long.

Box joints cut with your CNC router can be set to vary the width of the fingers for different combinations. A favorite look of mine is to have the fingers narrow at the center of the joint and then grow progressively wider toward the outer edges.

Box joints cut with your CNC router can be set to vary the width of the fingers for different combinations. A favorite look of mine is to have the fingers narrow at the center of the joint and then grow progressively wider toward the outer edges.

Your CNC router offers many different joinery options, from exposed and visceral to clean and concealed. Consider how you can combine tools such as a handheld router to open up new possibilities. There are many more joints waiting to be discovered, so start thinking!