Among the many modern adhesives available to woodworkers, cyanoacrylate stands alone in its wide range of applications. Often called “super” glue, cyanoacrylate can tackle some woodworking chores that other, more conventional adhesives simply can’t touch.

WHAT IS IT?

href="https://www.amazon.com/gp/product/B0000DD1QQ/ref=as_li_qf_asin_il_tl?ie=UTF8&tag=activeinterest-woodsmith-20&creative=9325&linkCode=as2&creativeASIN=B0000DD1QQ&linkId=a863112641f330667247f09547a3dae6">Cyanoacrylate is very different from the PVA glues used for most woodworking projects. In fact, chemically it’s closer to an automotive body filler (like

Bondo

) than any [woodworking glue](https://www.woodsmith.com/review/best-glue-for-wood/). It’s categorized as an acrylic resin. But unlike most two-part resin glues, it doesn’t need a separate hardener. Instead, water acts as the hardener. It requires moisture to set up properly. But it also has a few other properties that make it an indispensable glue for woodworkers.

QUICK ADHESION. Cyanoacrylate bonds almost instantly, so it’s perfect for quick repairs or situations where it would be awkward to apply clamps. Unfortunately, this means it’s also tenacious if you get it on your fingers.

BONDS DIFFERENT MATERIALS. Another nice thing about cyanoacrylate is its ability to bond a wide range of materials, like the pewter insert and the wooden box in the main photo. This can be especially useful for inlay work, allowing you to use exotic materials like shell and stone as inlay material.

It’s also helpful for making jigs in the shop, attaching wood and plastic (like Plexiglas ) with a reliably strong bond. If you run into a situation where the glue doesn’t seem to be sticking, you can add moisture by exhaling on one surface, like you would if you were cleaning your glasses.

DIFFERENT VISCOSITIES. With thin, medium, and thick formulations available from most manufacturers, cyanoacrylate is easily the most versatile glue on the market. The thin formula flows almost like water. Its wicking action is a great help for filling in small cracks. Once inside, it seals the crack quickly and permanently. The medium and thick viscosities of glue are more suitable for larger repairs and inlays.

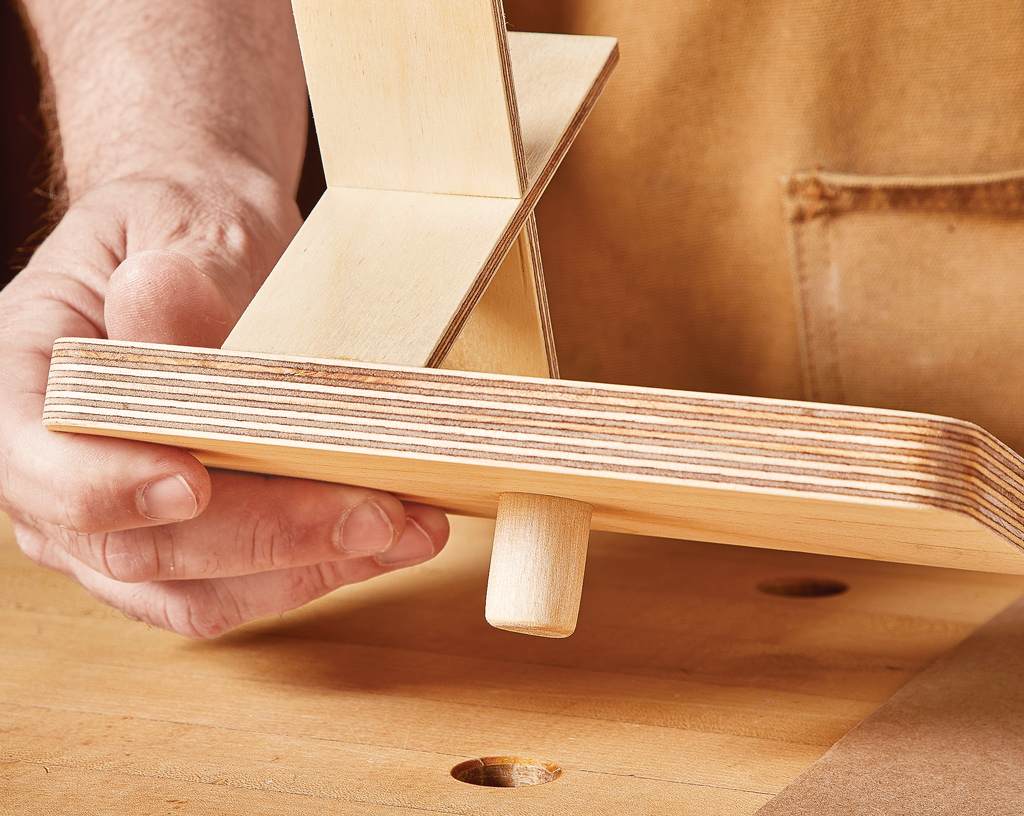

SHEARING STRENGTH. Another unique property of cyanoacrylate is its relatively low shear strength (force parallel to the joint line). This can be used to good effect, however, when you need a temporary bond. While it’s nearly impossible to pull apart two glued surfaces, you can tap one of the pieces from the side and crack the bond.

This characteristic means it’s perfect for positioning hardware while you lay out and drill screw holes. It also makes cyanoacrylate useful in woodturning. For example, you can attach a small block to a blank to turn a tenon for gripping the blank in a chuck. When you’re done, you simply tap the joint from the side to release the bond.

FINISH. You wouldn’t consider most glues suitable for use as a finish, but cyanoacrylate actually works very well on small turnings. It provides a hard, glossy finish with plenty of protection for the wood. It’s especially useful on woods that are too oily to take a conventional finish. You can see this in the photo at right.

REPAIR WORK. The uses for cyanoacrylate I’ve cited so far easily earn it a place in the shop. But when you learn to do small repairs by mixing it with sanding dust, you’ll have a great way to save a workpiece that might have otherwise ended up in the scrap pile. All you need to do is scoop up some of the dust and you can make a repair in minutes. For the highest-quality results, I usually sand a piece of matching scrap to collect the fine dust to mix in with the glue.

With so many useful applications, I consider cyanoacrylate a must-have item in the shop.

Must Haves: De-Bonders & Accelerators

In addition to a few different types of cyanoacrylate, there are two accompanying products you’ll want to keep on hand. The first is a de-bonder. Although you can sometimes clean up cyanoacrylate with acetone, it’s never completely effective. A de-bonder dissolves the glue quickly. I’ll confess I seldom use a de-bonder on projects. But when you’ve accidentally glued a finger to a project part, or worse still, to another finger, you’ll be glad you have a bottle around.

The other handy product is an accelerator. Like the name implies, a quick misting of a project part makes the cyanoacrylate bond instantly and permanently. You’ll want to use some caution, however, since there’s no adjusting the pieces afterwards.