My Desk Project

I don't really need another desk. We have four in our house already. But when I saw Seigfried Farnon's desk on All Creatures Great and Small, I knew I was going to build one. The desk is unique in that above the drop front worksurface is a short bookcase with a pair of doors. Most desks that I see in that style have either nothing or a monumental tower of a case.

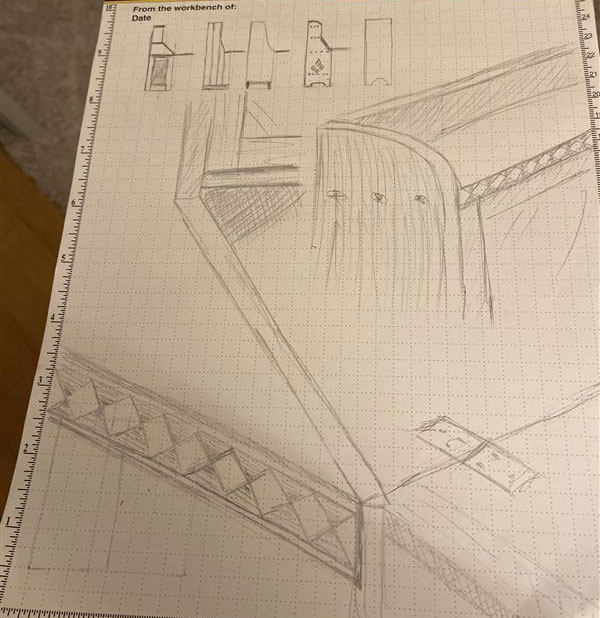

However, I don't want to make a straight up copy. As I thought and sketched this project, I found a few details that I'd like to incorporate: I'd like to add a cutout to the side, similar to a wall shelf we did on the TV show. Above the bookcase, I want a gallery-style shelf that acknowledges that stuff will get set up here. Finally, I like the diamond carving that I saw a lot of in England this past fall. I used it on a picture frame a few years ago. The diamond molding will coming handy as a way to conceal the whorl of knots in the pine I plan to use for this desk.

Here are a few images and sketches that shows where I'm at right now.Kind of a mood board, of sorts.

Logan's Candle Table

In the conversation about mockups, Logan mentioned the candle table he's building for a church. Here's how it looks now.

Saw Till We had a question about the Saw till lurking in the background of a recent cover of Popular Woodworking. The project was featured on the Woodsmith Shop.

Transcript

So you can make your own ShopNotes Podcast graphic novel.

Phil (03:24.138) The Shop NotesPodcast is up to episode number 252 everybody. I'm Phil Huber joined by John Doyle and Logan Wittmer. Here to continue in another great conversation of woodworking, frankly nonsense a lot of times is what it is. thanks for listening. If you want to get in touch with us, you can do that. woodsmith at woodsmith.com or leave a comment on the shop notes podcast YouTube channel. If you want to watch it or listen to it on YouTube, which I feel like a lot of people are doing that now. So check it out. Shop notes podcast over on YouTube, like subscribe, ring the bell. So we'll kick things off with a pay the bills moment with a word from our sponsor.

This episode of the Shop Notes podcast is brought to you by Gorilla Glue. When you're working on a project in the shop, you're putting in hours of effort. And the last thing you want is for it to come apart because the glue didn't hold. That's why you should keep a bottle of Gorilla Wood Glue on the bench. It's non-foaming, cleans up with water, and dries a natural color. And of course, there's the reliable Gorilla strength you can always trust. Also check out Gorilla Wood Filler for strong, durable repairs.

Gorilla is strong enough for the pro and easy enough for the beginner. Built by you, backed by Gorilla.

All right, let's kick things off here with some commentary from previous episode.

Phil (06:06.922) Jacob Schenker writes, hey, what's the status of Phil's final shop tour episode? I'm in the middle of not right now currently filming it, but I'm filming it over this week. So got a couple of segments in already. Then it's up to Nate to get that edited and out the door. So that's where we are on that.

John Doyle (06:29.177) I was kind of worried there that you had a shop tour final episode. Like this is it. This is the final episode. Goodbye everybody.

Phil (06:33.428) Right.

Yeah.

Phil (06:40.362) SS Frank says, voted in the Grizzly Makers Challenge. There were many great projects and it was overwhelming to choose. Then I saw a kid with a wooden knife. His smile said, look what I made, not say cheese. I knew he couldn't win, but a vote could boost his interest or confidence. Enjoy the episode.

Logan Wittmer (07:04.041) and it made me feel really good about myself. Thank you.

Phil (07:10.186) Stiegs writes, Logan has pop wood done an article on the saw till hanging on the wall behind the shaker bench on the cover of 286.

Logan Wittmer (07:20.947) Yes, we have. I'm gonna leave it there because I don't remember what issue off the top of my head.

John Doyle (07:28.165) I'll do you one better. We did that on the TV show. They can go to woodsmithshop.com and get the planets for free. Right? last last season.

Phil (07:37.16) Right. Yeah, that's the one. That's the one we did. Yep. Season 19. Yeah.

Logan Wittmer (07:38.974) Yes?

Logan Wittmer (07:44.682) It was project 2405. I don't know what the hell that means. Maybe 2024 month five, April.

John Doyle (07:44.685) And somebody.

Phil (07:59.487) Maybe?

John Doyle (08:00.197) Sure.

Logan Wittmer (08:00.425) April 24 issue.

John Doyle (08:05.539) Not only that, somebody came to our open house for woodworking in America here in the studio and took that saw till that we built a TV show home with them. They loaded it up in their convertible, the back of their convertible. Yep. Drove off with it.

Logan Wittmer (08:19.592) Like straight up, like, Verbal Mustang.

Phil (08:26.909) That's really why people need to come to the open house for woodworking in America, because you just never know what's going to happen. It's a wild card event.

Logan Wittmer (08:39.656) It was, it was April, 2024 issue number 277. It has a beautiful photo on the front cover of a ring neck pheasant carved by Jennifer Felton, world champion bird carver. I don't have that issue. It might be in my cabinet, but yep, it's on there or go to woodsmithshop.com. The plans are available there.

Phil (09:08.872) John Doyle (09:10.853) How do you become a world champion bird carver?

Logan Wittmer (09:13.999) You have to enter the World Championship Bird Carving Contest and win.

John Doyle (09:21.699) I mean, is it done on site or you just enter a carving?

Logan Wittmer (09:24.042) It is. No, it is. It's a big thing. there is... Okay, so I'm gonna go down a rabbit hole for a second. I learned all this when I was up shooting with Jennifer. There's bird carving as a entity, but then there's subdivisions. So there are decoys, there are game birds, there are raptors, there are sun birds. Like there's all of these subdivisions. In each subdivision...

John Doyle (09:30.777) Okay.

Logan Wittmer (09:53.45) there are different tiers. So there are, there's amateur, there's pro, there's like master. Um, so like you have to win, like, don't remember how this goes, so I'm going to get this wrong. It's like, you have to win like three times to be promoted to the next tier. Right? So when you start looking at all these world champion bird carvers, Jennifer is, think the,

Anomaly a she's a fairly young woman But the the big anomaly is that she's young because I think a lot of these like World champion carvers are like in their 90s because it took them that many years of winning to be promoted to master so but like Phenomenal absolutely phenomenal you would you and you guys have been to the state fair you guys have seen the the type of carving these people do it's like It's hard to tell on a well done

John Doyle (10:36.931) Yeah.

Logan Wittmer (10:52.211) bird carving, is that a mount or is that a bird? A wood carved bird, like crazy, absolutely crazy.

Phil (10:57.826) yeah.

Yeah. Especially when it's not just the bird, but it's the setting that they're in that is also carved. So it's not like a carved bird on a branch that they found outside in the timber. It's a carved branch.

Logan Wittmer (11:08.967) Yeah.

Logan Wittmer (11:19.75) Yes. Yes.

Phil (11:21.245) that is then painted to look like a real branch.

Logan Wittmer (11:25.597) Yep, yep. Some of the things I saw when I was with Jennifer, she lives up in Storm Lake, Iowa, so a couple of hours north of us. Her studio's beautiful little shop on her property. Lots of big windows, a lot of light comes in. She kind of has, I'm not going to call it a showroom, but it's kind of her working area. It's just a big room, has a desk, has a large work table that she does a lot of her work at. But then around the room, she has a few of her birds that are finished.

There was a period during the COVID times where the world championship for carving was not going on. So she had built up this kind of inventory of birds that were going to the championship. But a few of them were on display there. And it's like she had a giant eagle. It was actually, I think it was a half size eagle. So it was a half size eagle perched on a rock.

in the middle of water with a trout in its talons. And I'm like, this trout is good enough to, this dead trout that is a subsection of this bird carving is good enough to win the fish carving championship. ridiculous, absolutely ridiculous. But the rock that the bird was on, the eagle was on was a giant like walnut burl that she had sculpted and stuff.

They're a different breed.

Phil (13:00.777) All right, I don't know if I lost connection there for a second or.

John Doyle (13:03.951) Yeah, I don't know. Yeah, I'll, you two froze. So does that mean I froze? I don't know.

Logan Wittmer (13:05.649) I everybody flash.

Phil (13:07.113) Yeah.

Phil (13:12.317) Yeah. All right, let's see. We have a...

Phil (13:19.817) Bony board wood shop says John says he has no issues with shop Smith but his face while Phil read the shop Smith email said otherwise. Although at least he stayed, Logan just got up and left.

John Doyle (13:30.949) Yeah, look it's not the first time my face has got me in trouble, okay?

Logan Wittmer (13:40.193) Hehehehehe!

Phil (13:40.359) Hahaha!

Logan Wittmer (13:44.069) It's funny because I tell my wife that all the time. I'm like, you're saying one thing, but your face is telling me something completely different. That leads down a Logan gets in trouble rabbit hole quite often.

John Doyle (13:57.104) Yeah. Yeah. Look into my eyes. I had do not have any problem with shop Smith. There.

Phil (13:59.69) Michael Thompson.

Phil (14:09.747) Michael Thompson says, a cart is just a state of mind, deep thoughts by John Doyle. And that was, that one was.

Phil (14:19.087) philosophical. He also writes, think episode 252 should be a Socratic style discussion of the cartness of the cart. We might, in order for that to happen well, we might have to postpone that till from this episode.

John Doyle (14:36.857) Yeah. Is cart a spectrum? Cartness? You know, there's level of cartness. I don't know. Rather than a go, no go on the cart.

Logan Wittmer (14:39.723) Yep.

Yes.

Phil (14:47.877) I would, yes, because I think you could do like the wheelbarrow style carts where they really only have two wheels and then two legs. And then you just pick up one end and move it around. And then I think you get into the arrangement of the casters and type of casters. And then that's where you.

John Doyle (15:04.581) Like the non-swivel casters that are just one directional and then you bring in swivel locking versus non-locking.

Phil (15:10.525) Right.

Phil (15:14.087) Yeah. And then you do the ones where it's like two fixed casters in the middle and then single ones mounted on the ends centered so that you could do like the spinny cart style.

Logan Wittmer (15:27.918) like the panel carts at Menards.

Phil (15:30.065) Yes. Yeah.

Phil (15:34.973) Yeah, there's a lot that's going on there. He also says, also Logan invest in an infrared thermometer pointed at the stove, pull the trigger and display the surface temperature of your stove.

Logan Wittmer (15:47.928) You make the mistake of thinking I don't have seven of

John Doyle (15:51.301) you

Logan Wittmer (15:53.222) Do I know where they're at is the question.

Phil (15:59.144) Right, which speaking of philosophic questions like if you have something but don't know where it is, do you really have it?

Logan Wittmer (16:07.587) Yeah, I do that with cock guns. Like, every time I'm at Menards and I buy a tube of silicone, I'm like, yeah, I don't know where my cock gun is. Buy one, use it, throw it in the bin with the other 12 cock guns.

Phil (16:10.599) you

Phil (16:24.241) It's like the paint or finish can openers that we have in the finish room. I swear I go in there and I can't find a one of them. John was helping me move something in there this morning and right where I wanted to put my work piece, six of them on that one cart.

John Doyle (16:40.677) They're like cockroaches. turn the lights on and they just scatter.

Phil (16:49.673) All right, there you go.

yeah. So continue to send us in questions and comments on podcast episodes and topics. It's really fun for us to be able to read through those and keep up with people. Now, in the last issue of Woodsmith, I had posed a question on, in the editor's letter, which to be honest, I write those knowing that most people don't read them.

And I know Logan has to do the same thing at Popular Woodworking.

Logan Wittmer (17:28.016) Yeah. I'm always surprised when somebody does read them. I'm like, yeah, like somebody's actually reading that crap.

Phil (17:32.167) Right, and then responds to it, ho!

Phil (17:37.832) Now what? So I had several people write in for that and I just wanted to share a few of those. Tom from Montana writes, great job as always on the magazine, TV show and all you guys do for woodworking. As a high school shop teacher, intro to woodworking, carpentry and cabinet making, and a carpenter during the summer, it's rare I have a day without sawdust flying in some way, shape or form. Even though I'm constantly constructing something,

or instructing the construction of something professionally. In the spare time I do have, I enjoy creating in the shop. Usually the goal is to build gifts for Christmas or special occasions along with developing my own skills and try techniques I have not used before, along with designing new project ideas for students. I keep myself challenged with new shop objectives, always kept my personal shop time fresh, keep up the good work.

So first of all, thanks for writing in and reading that. Second of all, thank you also, Tom, for being a high school shop teacher, because I can imagine that that's not an easy task.

Phil (18:49.001) John Wilson writes, that's a good question you posed in the from the editor sawdust section in the last issue. Why is it we do woodworking in our spare time when we also do it for work? Simply put, at least for myself, I can't help it. I'm a custom cabinet builder, having run our shop for over 20 years, designing, building and installing our cabinetry in the high end custom homes we build. I do consider it a tremendous privilege

to love what I do for work enough to do it outside of work and largely unpaid. That being said, I specialize in making furniture at home, prioritizing hand tools and visible joinery. This particular genre I don't get to do at work hardly ever, so it's a departure from the daily norm.

And the last one from Larry, who writes, first, let me tell you, I'm pushing 80, raised as a farm kid, so got exposed to woodworking from the get go. I've had a small shop in various basements and garages since my late 20s, and I've built everything from birdhouses to coffins. For Halloween, not the real deal. I'm a communications engineer by trade and a woodworker for many reasons. One, I like to work with my hands. Two, it's a creative outlet.

Three, solitude. Four, I use mostly repurposed wood, so there's the satisfaction of not wasting a resource. Five, the freedom to do what I want when I want. Many of my projects are whimsy, whirligig, odd-shaped boxes, toys for the grandkids, et cetera. And then finally, the pure satisfaction of looking at a finished project and being able to say, I did that. And in the case of furniture, everyday use.

Phil (20:36.585) There you go.

Phil (20:41.757) Thanks again to everybody who wrote in for that on the editor's letter from the current issue of Woodsmith that you can check out. That's number 282 currently out in people's homes and on the newsstand. So you can check that out.

Phil (20:59.081) Let's see, because we had that comment and you were fighting with fumes and smoke, how has your wood stove settled in?

Logan Wittmer (21:11.555) Uh, fantastically. I will say, um, and you know, obviously I know this,

Phil (21:13.714) Yeah.

Logan Wittmer (21:21.2) Scraps from the shop don't last very long. Just because there's lots of surface area there and they burn quickly. I think that if you want a good long burn, need, you know, dry bigger pieces of, you know, long burning hardwoods like oaks, you know, whatever.

So like the last, when was that? Saturday, Friday, Saturday last week, it got cold. Like it got down into, it got blow freezing. So I was like, oh, perfect time. You know, so I started getting the stove going and really like burning scrap out of the shop. After that last burn, I think probably when we were podcasting, got it up hot enough that it took everything off.

Yeah, no smell, no smoke. Works great. So love it. It'll be interesting to see. It's very easy to get the shop up to like 78 degrees, which is pretty warm. Which we're at the time of the year where I'm kind of reveling in that heat. It's like, oh, this is really nice.

Phil (22:34.088) Right.

Logan Wittmer (22:46.306) I won't obviously keep it that warm as a kind of standard practice. I think what I will probably do is try just to keep it mid-60s in here. I put a blower on it. I got a ceiling fan, so everything's on. Remote control used turn on. Yeah, it's working great.

Phil (24:13.361) We'll have to remember to let Mark know to start keeping scrap again in the shop too.

Logan Wittmer (24:21.659) I told him. Yep, told him. Yep. Yep. So I mean, I have, you know, all the sawmill scrap I have, like I have a ton of it. It's just not dry. So it's like it's like you can burn it, but you're creosoting up your your chimney and you don't want to do that. You know, honestly, luckily, my chimney is a very, very straight run. It is straight up.

There is no bends, are no kinks, are no elbows, nothing. So is it the end of the world to creosote up the chimney if I clean it every year? Probably not that big a deal, but I don't want, you you're losing a lot of efficiency by converting water to steam. So gonna try to avoid that.

Phil (25:08.455) Yeah. Yeah. All right. I would imagine on some of the sawmill waste too, like that's going to be the same problem with scrap is that they're going to be, there is the potential for being relatively small pieces, right? Or.

Logan Wittmer (25:24.009) Yeah, that stuff usually stays in the parking lot here. And then it gets scooped up by the skid loader. So it's like, you know, one thing that this might make me do is as I'm sawmilling, ignore the cat running around doing parkour if you guys see him. What this might make me do is the opening cut on a log or the wasting cuts on logs. I might be a little more tempted to make a bigger cut than I would in the past.

John Doyle (25:27.621) you

Phil (25:31.069) There you go.

Phil (25:53.203) be a little bit more generous, like this one's for me.

Logan Wittmer (25:53.441) You know, yeah, yep, So, but we'll see. Yeah.

John Doyle (25:59.888) Do you typically not burn something with a lot of bark on it? Like, does that burn? Or you can? Yeah.

Logan Wittmer (26:06.279) You can it just is ashy Yeah, yeah, actually I had so I It's interesting and anybody that grew up on a farm or anybody that grew up burning wood or anybody that does burn wood will know this There are certain woods that are ashy compared to other woods My my grandpa was told me he's like at Elm he's like I love burning it cuz it's it's really He said it sparks. That's the only bad thing. He said it sparks, but he's like

there's no ash when it's done. And I'm like, okay, like I get that. The mahogany that I have been working with for this table, it leaves this fluffy white ash that looks like marshmallows. It's very weird. Yeah, it's just interesting because there's different ash that's left over from various different woods. I burned through

Yeah, it's pretty cool because you can tell the denser woods like oaks like when I throw oaks in there, you know all the flooring I cut out of the bathroom in here and burned that all up. That stuff burns great. Like I could load up the stove, you know 10 o'clock at night and the next morning I saw the hotbed of coals I just throw wood right on. So yeah, so. It's pretty cool. I think I think I'm going to really enjoy having it in here.

Phil (27:22.597) okay.

Phil (27:29.075) Sure, I can see that.

Logan Wittmer (27:34.954) So I bought a water humidifier, a cast iron stovetop humidifier. It's literally like a crock pot with a perforated lid on it. That's cast iron. It's amazing how fast you will boil off a gallon of water. three hours it boils it off. Doesn't seem to do anything for my humidity in the shop.

Phil (27:50.076) Okay.

Phil (27:56.1) I'm sure.

Logan Wittmer (28:05.159) Absolutely nothing.

Phil (28:07.547) Yeah, I would imagine you have a lot of places for that humidity to go run and hide before it's going to make a big deal in the shop environment.

Logan Wittmer (28:18.004) Yeah, well, and having the perforated steel roof. I think it can probably go right out the perforated steel into the attic space.

Phil (28:23.943) Phil (28:33.129) All right.

Logan Wittmer (28:33.405) that's not really a moisture barrier. So yeah, I think in farm town we call that pissing in the wind.

Phil (28:35.689) That's true.

Logan Wittmer (28:48.123) isn't gonna do anything. You do it all you want.

John Doyle (28:53.145) Well, depends which direction the wind's blowing.

Logan Wittmer (28:55.007) That's true.

Phil (29:01.597) All right then.

I've been working on the tool chest project with my son again, and that was what John helped me bring in was the top of that was just shy of two inches thick and like 26 by 53. So it's a goodly sized glued up panel and put some finish on it. I'll put a picture in the show notes page.

John Doyle (29:27.845) It was a hunk of beef.

Phil (29:34.237) I used tongue oil from Old Masters that I thinned out with some turpentine just to make it a little... especially at this time of year, tongue oil tends to be a little syrupy putting it on.

Logan Wittmer (29:48.329) just to make it smell disgusting.

hate turpentine smell. Least favorite solvent. Well, low odor neural spirits is probably above that.

Phil (29:52.553) Thanks.

Phil (30:04.958) I like the smell of turpentine. I'm on record saying that. Anyway, so I put that on and it's amazing. Never ceases to amaze me putting on the first coat of finish on something to see how the color transforms and being able to see the very subtle differences in color and grain from piece to piece and even within a board. So it's really, really cool to see that.

Phil (30:34.814) Then I have a question for the both of you. The case of this toolbox is getting a hammered paint finish. And we bought from Menards the stuff in a can so we could roll it on instead of using like 9,000 spray cans. And like this week here in Iowa,

The weather is gonna be like in the 60s, hit 70s. What are the temperature ranges in your experience of using a paint like that that I can apply that on?

John Doyle (31:17.153) Usually like lows in the 60s and 50s seems like kind of my threshold.

Logan Wittmer (31:20.88) I'd 50 is where I would go,

Phil (31:24.938) Yeah, it's kind of what I was thinking. I kind of want to make some hay on applying that.

see if I can get that taken care of.

John Doyle (31:35.141) Yeah, it's probably too big to bring in here, I'm guessing.

Phil (31:40.732) Yeah, it wouldn't really fit in my car and it's pretty heavy at this point too.

Logan Wittmer (31:48.21) That hammer paint uses my favorite solvent, which is xylene.

John Doyle (31:55.777) Mm-hmm.

Logan Wittmer (31:58.333) Full ethanol.

Phil (31:59.955) Yeah. Because if that one doesn't say cancer, nothing does.

John Doyle (32:00.152) you

Logan Wittmer (32:04.509) That's right, my favorite flavor.

Phil (32:09.512) Yeah, which is kind of what I was waiting for you to say when you were talking about how you disliked turpentine. And then I was like, and then I'm like, I give you xylene.

Logan Wittmer (32:19.851) Yup.

Logan Wittmer (32:25.059) only second to blanket wash from the print shop.

Phil (32:28.908) yep.

Logan Wittmer (32:30.617) yeah.

Phil (32:32.606) Yep, I remember having a couple of jugs of that laying around.

Logan Wittmer (32:36.681) yes.

Here, baby Phil, go nighty night.

Phil (32:42.058) Smells like sleepy.

Phil (32:48.712) Although it is funny, because I remember as a kid helping out a neighbor across the street, I don't even remember what we were doing. And then the bunch of us ended up with a bunch of just junk on our hands. So he's like, here, let's clean that off. And he goes and grabs the gasoline for the mower. And then we were like scrubbing our hands with gasoline thinking like, this is the coolest day of my life.

Logan Wittmer (33:05.393) Mm-hmm.

John Doyle (33:12.581) you

Logan Wittmer (33:14.653) My grandpa used to do acetone when we were painting fishing jigs. I was like, why is this so cold? Well, it's because it's evaporating like immediately.

Phil (33:19.966) Okay.

Phil (33:31.952) All the fun stuff.

Phil (33:37.578) All right, John, what's going on with you?

John Doyle (33:39.941) Sounds like we're back in full production mode for the TV show next week. So I feel like we're getting a little Tom Sawyer on this because we're building a vanity for Logan's bathroom shop bathroom right out of the gate.

Logan Wittmer (33:57.691) Heck yes!

Phil (33:59.017) That thought had crossed my mind, yes.

John Doyle (34:01.347) But I think people don't realize that half the projects we do on the TV show are because that we want them. It's like, I'm to take that home with me. They're for us.

Phil (34:16.884) Well, which to be fair is how a lot of projects get selected, I think for probably both of our magazines, Woodsmith and Popular Woodworking, where it's like, I need a blankety blank. And then it's like, that's a project.

John Doyle (34:23.823) Yeah.

Logan Wittmer (34:24.697) yeah.

John Doyle (34:31.439) Yep. Yeah, back to the one guy that wrote in about doing woodworking in our spare time or whatever. And it's like, nah, we just suckered people into paying us for doing woodworking in our spare time. don't tell anybody though.

Logan Wittmer (34:31.58) Mm-hmm.

Logan Wittmer (34:44.7) That's right.

Phil (34:45.213) you

Phil (34:49.428) I'll put a photo of the plan, but for people watching on the YouTube, was originally from the now defunct Workbench magazine that was part of our family of titles. This one was originally built in cherry, the shaker style cherry vanity, had a vessel bowl on it, and was designed by Kent Welsh, I believe.

He had a fondness for the shaker style.

Phil (35:26.974) But we're not building ours out of cherry, though.

Logan Wittmer (35:31.002) Mm-mm.

Phil (35:32.894) We're using Logan's favorite workbench wood, which is ash.

Logan Wittmer (35:37.181) Swamp Ash!

Phil (35:42.558) So that was stuff that you had milled, right?

Logan Wittmer (35:44.868) Yeah, this is one of the few trees that I milled and I don't remember milling. Like that doesn't happen very often. Like I think it's a little bit of my little bit my, my tism ability is that I can remember almost every like any of the lumber that's in my storage and there's lots of it. I remember milling most of it.

It's like Phil being able to recall what issue something was in from 37 years ago. I'll be starting to remember, I know two of these boards have nails in them. I remember hitting them. I had these pieces of ash and I would think I would remember it because whenever I saw ash, I cut it at two inches thick or three inches thick because it goes to Las Vegas. It goes down to Jimmy for turning. That's just what I saw the ash for.

These ones, are they five quarters, John?

John Doyle (36:47.145) Yeah, they're at an inch and a quarter, yeah.

Logan Wittmer (36:49.18) Yeah, so they're they're thicker and I'm like, I don't know why I would have sawed them like that. I mean, I remember stacking them in the garage, but I don't remember sawing them. I had them stood up along the wall in the garage and I remember standing them up over there saying, these are really nice ash boards, like pretty straight grain, not a whole lot of knots. There are some knots on them, but not a whole lot. And so I'm going to stick these over here because I'm finding it like there's enough here for a good project. And that's.

what we're doing now. So, yeah.

Phil (37:22.888) It's also nice because it has a good color to it, because I feel like a lot of ash can have a.

Phil (37:31.72) I don't know, it's a pale colored wood to begin with, but some of it has that kind of yellow, yellow green kind of weird color that makes it tough to do anything with other than like stain it heavily.

Logan Wittmer (37:34.383) To Yellowwood, yeah.

Logan Wittmer (37:47.152) Mm-hmm.

Logan Wittmer (37:50.607) Yeah. So I started sorting through them to that sorting through them. I brought everything that was standing there in. But I started loading them into the truck to bring them in. And I'm like, what is crunching under my fingers as I'm like loading them up? And I realized that, we are in stink bug season here in central Iowa. And there was lots of them. They were like.

John Doyle (38:07.749) you

Logan Wittmer (38:19.855) They were because all these boards are standing on end, you know, so there's space in between the boards a little bit and they're all like in these little warm nests of stink bugs. And there was lots. Yeah. John John mentioned that he was finding squished squished bugs. So maybe that's where the swampy smells coming from.

John Doyle (38:30.991) Yep, I'm finding them.

John Doyle (38:38.243) Maybe, I bet.

Phil (38:44.638) Although we had those cold days, so maybe that helped ice this current generation of them.

John Doyle (38:51.277) Yeah, I don't know. Do they just like hibernate or does that kill them? I don't know.

Logan Wittmer (38:52.366) See.

Logan Wittmer (38:56.162) I don't

Think bugs are dicks.

John Doyle (39:02.073) Yeah.

Logan Wittmer (39:05.306) Can't get rid of them. Cannot get rid of them.

John Doyle (39:05.413) Nope. And they're impervious to salt blasts. They're armor plated. Yeah.

Logan Wittmer (39:11.546) Yeah, you need armor piercing. Yeah. Yep.

Phil (39:17.908) Yeah, the bug assault, think for the most part, especially here in the studio, because when we have nice days out, the studio room has no windows in it. So it feels a little bit like a cave sometimes. So if it's nice out, I'll leave the door open. And then in fall, the stink bugs discovered that the door is open. And there was one day where all around by that opening, there were probably 30 or 40. So I kind of went to town with the bug assault.

which I realized really only stunned them a little bit. So if I could get them to fall down from the ceilings and walls, then they got stomped on, but.

John Doyle (40:00.678) Double tap.

Logan Wittmer (40:02.425) Yeah.

Phil (40:02.632) Yeah, it's either a double tap or you got to get them flipped upside down on the soft underbelly because they're like the armadillos of insects.

John Doyle (40:06.445) Mm-hmm. Yep.

Logan Wittmer (40:09.366) It's...

Phil (40:15.092) So, yeah.

Phil (40:19.102) All right. One last thing before we wrap things up here is I'm working on building a desk for myself. I'd like it to be in my house. I think I've mentioned this before, but we have like five desks already at our house. I don't know that we need more, but this desk project is something that's latched hold of my psyche in some sort of way and will not let go.

Phil (40:46.41) And I've been, whenever we get plywood deliveries, Liberty usually sandwiches the plywood in four by eight sheets of corrugated cardboard, which is delightful for many reasons. But we also have almost a full bay in the shop that's just corrugated cardboard. So I took one of those and I drew out.

Logan Wittmer (41:02.073) Hmm.

Phil (41:12.586) the profile, the side profile of what I think the desk should be, just so that I could kind of get sizing proportions right on it. Because I can sketch stuff on graph paper all day long and then you build it full size and it's like, ah!

John Doyle (41:29.477) real.

Phil (41:29.982) That's not what I thought.

Phil (41:34.419) So, and then I'm gonna make it out of white pine. This could, should come as no surprise to anybody. But the white pine that I got from Logan, very generously, has, as white pine does, rows of knots periodically, depending on how good of a growthier it was for that tree. Warrels.

Logan Wittmer (41:35.353) Yeah.

Phil (42:03.814) is the technical word there. And the desk that I want is going to be like a drop front desk, but with a small bookcase at the very top of it. I'd like to do it all in single pieces, the sides, glued up panels. But where the whorls are, I don't really want that knotty pine look to it, because it's definitely not a country bench or a country desk.

And I was going over these boards six ways to Sunday trying to figure out like, what if I cut here and then glued up here? And considering that I'm the kind of person that will glue up plywood, went kind of bananas trying to figure out how I could do this. And then the thought came to me because of some of the other detailing that I want to do is I'm going to position that row of knots.

just below where the desktop is going to be. So where it goes like the maximum depth of the case, and then it tapers back for like that slant front of the desk. So just below that, that's where the knots are going to be. But then I'm going to route a shallow channel and then put in like some diamond banding or diamond carved molding to cover that up.

So it adds a little textural detail, covers it up without it being like, look, I'm covering up knot holes, kind of a thing. So we had done that diamond molding profile on a toolbox or tool cabinet years ago in Woodsmith. And then I had carved some for a picture frame that I have in here. And it's kind of a fun motif, relatively easy to do with a chisel.

and is also something that's really common in like the Cotswold School of English arts and crafts furniture.

Phil (44:16.66) felt like it was a good way to rescue those pieces. And with that, I have plenty of length now to be able to break up those boards. So I'm looking forward to that.

John Doyle (44:29.167) War of the worlds, am I right?

Phil (44:31.249) Yes.

which I'm sure is what Nate is gonna make the title of this episode now.

John Doyle (44:35.653) I hope so. I think I get a bonus for that.

Phil (44:42.76) Yeah. It's two times the cover bonus.

Logan Wittmer (44:44.268) You guys are getting paid?

John Doyle (44:46.085) Yeah.

you

Phil (44:52.884) That's how that works, I believe.

Phil (44:58.634) Alright, so those are my projects. Oh, one other thing is I was working on, I've talked about making some shrink boxes out of some fallen maple and I had cut those and put the bottom in, I don't know, two weeks ago maybe. And last week when we were recording the podcast episode, I had gone out to check on them and the boxes had shrunk a little bit, but you could still see gaps in different places around it and if I

kind of jiggled the box, you could hear him kind of rattle around. But like Logan said earlier, we had temperatures drop down into the 20s. Well, actually, it was lower than that. I think it was almost in the teens or something at night, which here in middle America sucks all of the moisture out of the air. All of it just rings it right out.

Logan Wittmer (45:46.187) Mm-hmm.

Phil (45:51.371) It's like a cold Arrakis. Anyway, so I checked on those on Sunday when it was still relatively cool out and the shrink boxes had shrunk all the way down on to the bottoms. No gaps, no light showing around them. And when you tap on the bottom, you can feel like, like it's just solid. It's kind of tight as a drum down there. So just a really

Logan Wittmer (46:17.399) Thanks.

Phil (46:21.278) That part is one of the fun parts of woodworking is just playing around with what wood does on its own.

Logan Wittmer (46:33.59) Yeah, it's funny you were mentioning sketching out stuff full-sized. I'm working on this candle table for the church, right? And I'm like, okay, standard table height's 29 to 30 inches. Like that's pretty standard table height. Now I'm questioning whether that's tall enough, but I'm kind of, at this point, it's full send.

Like, I don't have a good way to make it taller necessarily. Like, it's full send, so we're rolling with it. It's just one of those things like, hmm, maybe should've sketched that out. I was looking at my, I was like, okay, if somebody's putting candles in this thing, like, counter height is pretty good. Counter height's like four inches taller than when I made this thing. I'm like, shoot. So, I don't know.

We're going with it. It is what it is. We're going with it.

Phil (47:34.975) Okay.

John Doyle (47:35.169) a really really thick top.

Phil (47:37.674) There you go.

Logan Wittmer (47:38.134) Well, so it's actually a two layer top, if that makes sense. So it's like you got the frame and panel base, then you have a top on that. And then there is a five inch tall, let's call it a riser, for lack of better term, that will have a little corbels on it and stuff. And then another like little bit larger top that goes around it. So basically what that's doing is creating a recess for this stainless steel tray to sit inside of.

Phil (48:05.46) Okay.

Logan Wittmer (48:06.272) So like the entire thing is a little bit taller. Or it's double layer. So right now I'm looking at this frame and panel assembly and it's only like 22, 24 inches tall, maybe 24 inches tall. I'm like, this is such a squatty little thing. It's like a little bench. Well, it's because it gets an extra layer of tops added onto it. But at end of the day, I'm like, mm, I kind of wish I would have made it just a hair top.

We'll see though. I can extend from the first top to the next top, I guess, the frame. I can extend that. The initial plan was to make that five inches, that'd be a five inch deep tray. I can make that seven inches if I want and then add two inch blocking underneath the tray. So like I have ways to do it. It's whether or not it will look correct proportionally.

Phil (48:56.528) yeah.

Logan Wittmer (49:03.807) The other thing I was thinking of is maybe doing some, I have to look at the styling and see if I can make it look right. I could add some molding risers, you know, if you did like molding that was rabid that sits between the top and the case, you you can build that up pretty far doing that if you wanted. So we'll see, I'm gonna glue up the top, put that on there, see what it looks like. Some of this, some of,

Phil (49:22.751) sure. Yeah.

Logan Wittmer (49:32.745) Some of what we do for the magazine stuff is woodworking by eye in real time. It's like, okay, that didn't look right. Let's cut it down a little bit.

Phil (49:40.468) Yep. No, I'm quite familiar with that, which is why I bring it up on my desk because I don't normally draw stuff up full scale and I don't normally do like mockups or prototypes or whatever. But for this desk, it just was one of those things where I wanted to get as, get it as close to right as possible before I start.

Logan Wittmer (49:55.529) Mm-hmm.

Phil (50:09.032) like get halfway through and be like, dang it.

Phil (50:15.796) So, all right, we'll see how it goes. That's it for the Shop Notes podcast. Don't forget to like and subscribe on our dedicated Shop Notes podcast page over on YouTube. Otherwise, over at your local podcastery, check us out. If you give us a rating and a review that helps other woodworkers find the show and be able to contribute to even more questions.

even more comments and all the smart remarks that we can get.

Thanks for listening, everybody. We'll see you next time.