England Tour

In the middle of September 2025, I was on our first Woodworking Tour. We travelled to several sites in England over 8 days. The trip was a delight. Every time I go back over my photos, I remember something different.

During this episode, I talked about the experience we had with Joel Raymond. He's an oboe player and boxwood instrument afficianado. While thunder rumbled outside our 12th century church setting, Joel talked about history of the instruments he plays and makes. There were side discussions about the woodland management of box and the material's cultural history. His enthusiam was infectious.

I'm inspired by a wide range of woodworking projects, styles, and techniques. However, in the last few years, I've been taken by the idea of working primarily with softwoods. "Vegan woodworking" we joke on the podcast. These wood species are usually thought of as construction lumber or, at best, secondary materials on a project.

I'd argue that they deserve special treatment. So the last number of projects I've made have been from white pine mostly. And now after thinking about Joel's presentation, I may dive deeper into the cultural history and management of eastern white pine.

Several of my projects have been turned into courses. My workbench is made from white fir. The same goes for a small bookcase I built. The desk is my effort to take white pine to a refined level.

Listener Feedback

In a recent episode, we talked about woodworkers benefiting from metalworking skills and tools. Logan and I discussed small vertical mills. While vintage machines are lovely, Logan pointed out those made by Grizzly and Precision Matthews and worthy of consideration.

I have a narrow belt sander in my shop that I forgot about as a metalworking tool. Naturally, mine is a shop-made version we did on the TV show.

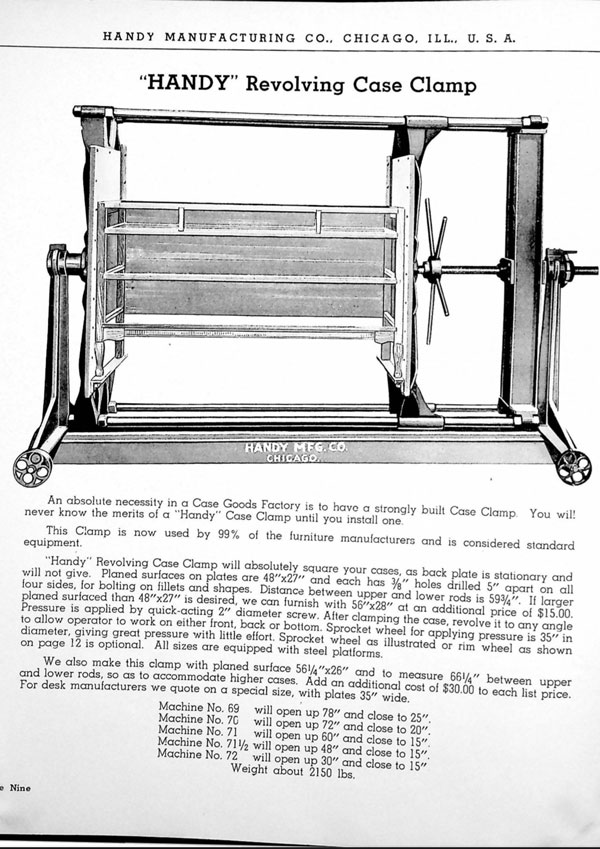

Vintage Tools: Case Clamp

Fresh off his success with his Moak jointer, Logan found a new old tool to love. This one is much simpler. It's a cast iron case clamp. Yeah, It's enormous.

Right now, the plan is to clean it up, use it for awhile and then maybe move it along to a maker who could put its impressive capacity to good use.

Transcript

In this transcript, you can see that a conversation converted to text is not the same as writing. Not by a long shot.

Phil (00:12.046) Hey everybody, it is the ShopNotes podcast. That's right, your favorite weekly woodworking podcast. Dropping a whole new episode. I'm your host Phil Huber joined by Logan Wittmer today. We've sent John on assignment. So we'll catch up with him on another episode. This is episode number 245. On today's episode, we're gonna be talking about some updates on some trips that Logan and I have been on. We'll get some viewer and listener feedback from comments and respond to those. We're also going to talk about when it's time as a woodworker to reach out and ask for help about problems that you have in acquiring tools. All that and more on this week's episode. A special shout out to our sponsor,

Phil (01:24.866) Now I'm gonna jump in here with some comments from the last episode. We were, we talked about a lot of stuff, talked about some metalworking tools and having, based on your shop experience, like you have a space where you can have a significant metalworking work area.

Phil (01:49.996) And I think it's important in any shop that you can have something where you can kind of dedicate a little corner at least to metalworking.

Logan Wittmer (02:01.303) Yeah. Or even a flex space. Like, doesn't have to be mail-working, but even a flex space where it's like, hey, this is the part of my shop that I fixed my chainsaw or my weed eater or whatever.

Phil (02:11.564) Yeah, yeah. Right. And because we've talked about in the past, having dedicated spaces, you know, that your woodworking area, if it's something that's special to you, that it doesn't turn into also the bike storage area and also the snowblower goes here in the off months. You know, you want to have that space carved out to be something that's for woodworking. But that said, you know, having a flex area to do

some of those, I don't know, gunkier jobs as they can be. Gabriel Webb says, I concur with the metal workers toolkit discussed on the podcast. I have the good fortune of separate spaces for my metal and wood shops. The wood shop is the nicer building, a detached one car garage. The blacksmith shop is across the driveway in an open front shed.

Depending on the resources available, a very basic setup for blacksmithing is a powerful addition to the wood shop. The proliferation of amateur knife makers has made entry level blacksmithing equipment easily available. Yeah. I mean, that's definitely metal working. I think that veers off a little bit, but yeah, you know, if you have a place where you can work metal hot is also its own.

Because you've even talked about that.

Logan Wittmer (03:39.533) Oh yeah, like I got the crap here to do it, just don't have the forge yet. Still looking for a forge, if anybody's coming to WIA and has one. Gotta get my shameless plug in there.

Phil (03:52.003) Right. Driftless Joinery says, late to the party again, metalworking toolkit I would add, a Palmgren drill press vice, the two and a half inch guy, specifically one that isn't complete Swiss cheese. Drill bits, fractions, numbers, and alphabet. Good countersinks and a couple of different size spot drills or center drills come in clutch too.

I have several manual and CNC mills I can use where I teach, but with a good vice and careful setup, I get about 90 % of my stuff done at home on a not so great old craftsman drill press with a long piece of aluminum extrusion I use as a fence. The biggest issue I run into is fixturing everything, but then having to raise or lower the table and losing position. There are some old gigantic drill presses with dovetail ways on the quill and table that solve this.

but they don't show up for sale very often. We have an old AV drill press like this at school that I'm still searching for a similar one for home. Some folks like to use blue or red Dicom to scribe. Blue Sharpie works well, dries faster and doesn't make my shop smell like a nail salon.

which is all, I think that's pretty solid. I mean, you even noticed that on your radial arm drill press that.

you know, there's the frustration of getting it all set and then realizing like, crap, this bill, this short little bit isn't going to come down far enough.

Okay, so riddle me this then, because I've seen like you have your vertical mill, sometimes called a called a knee mill. And then you have a drill press, which are

Phil (05:52.725) related, but not not super related. But then you also have something called a mill drill, which I think is kind of a hybrid, right?

Logan Wittmer (06:01.554) I believe so. I have never done much of in the way of like mill drills. I think most of the time those don't actually have like a Jacobs chuck. They have a Morris taper that you'd put a tapered bit in.

Phil (06:14.286) yeah, yeah, like a vertical mill.

Logan Wittmer (06:17.767) And yes, and to be fair, I did have one of those at one point, and it got sent along its way. Because it was huge and ridiculous.

Yeah, it's all about the side load. It's all about the side load because Jacob's trucks and even like even now that I've said that, Morris tapers are not meant for side load. So like, maybe that's not the maybe it's more of like a draw bar situation where you have a Morris taper with a draw bar and that's what's holding the cutter in. I don't know. But but yeah, like one would.

Logan Wittmer (07:00.587) could argue and one would not be wrong that everything I could do on my drill press I could do on my vertical.

You don't have the speeds per se, although I've never really put the belts in the gearbox into the high-speed situation on that thing to see how fast they could go. But that would be a decent argument that's like, you don't need both. And that would sure free up a space for a wood stove that we've been talking about.

Phil (07:10.062) That's true.

Logan Wittmer (07:38.846) But I don't know that we're ready to rip that bandaid off yet.

Phil (07:43.651) Yeah. Chris has a small, grisly mill, vertical mill, that is like drill press sized, but beefed out to be more of a mill. And it would be interesting to know, cause I've seen small little mills where it's like, yeah, you know, if I'm building model airplanes or drones or something like that, that's, that'll work. But I,

Phil (08:13.442) I feel like if you're going to have a small mill in your wood shop to do some decent sort of metal milling, like you'd want it to be solid. where...

Phil (08:29.548) And I'm throwing this out there for anybody. Where's the drawing? Where's the line? Either manufacturers and models or sizes where it's like, this is a toy making mill and this is like a mill that you can do stuff with.

Logan Wittmer (08:42.324) Yeah. So I know that, like that grizzly one, I haven't used it, but it seems like it's pretty good little unit for the price. Like it seems like it's a solid little dude. I think it has one horse. It's either one horse or a three-core horse. There is a company, God, the name's gonna slip my mind, that makes hobbyist-sized machines.

this is, it's on the tip of my tongue. That's frustrating. anyways, but they make like hobbyist little lathes and mills and they are super cool. They're not precision Matthews. Thank you brain. precision Matthews makes these little mills that I don't think that anybody would claim they are super precision. Like it's not a

you know, super precision, but it's definitely good enough to do anything you want to do at home. So, and they're kind of in that, they're kind of in that family of tools that you buy it and you know that there's a few small upgrades that you can do and add onto it immediately that just make it that much better. You know, it's not like the, you know, the old thing in in the machinist world was like, you go by the Harbor freight.

Logan Wittmer (10:11.506) little metal lathe, but here's the entire rebuild manual for fixing it and getting it to actually functional. It's not like that. It's more like, you you buy the precision Matthews little benchtop vertical mill, which might be, I don't know, 300 pounds. So it's still a hefty piece of equipment. But it's not like you are, you know, pulling it apart.

re-scraping the ways and doing all that stuff. It's more like, buy it, throw away these hand wheels that come with it, the DRO and the power feed and call it good.

But I think it's one of those things that.

It's almost with metalworking stuff.

quality of machine overtakes size in most regards, I think. At least for anything I would be doing. If I was an old farmer that was like, I need to rebuild this tractor tire and then they put on my vertical mill, which I don't know why you do that, that's not the, that's not what I'm talking about. I'm talking about more like most of us, what are we doing with it?

Phil (11:29.464) Right, that's true. I mean, and I think it plays out in the sense of, you know, like a vintage self-bend metal lathe. They made some pretty small ones, but those are robust tools.

Logan Wittmer (11:43.239) Yeah, yeah, they got some heft to them.

Phil (11:49.197) Yeah. ijwtbotdad says, I'm somewhat of a noob and have aspirations to reface our kitchen. After really thinking about and checking out a lot of videos, the drawers will need to wait until I feel like I won't spend a month on each drawer. And for how much drawer slides are, they should perfectly install themselves.

Logan Wittmer (12:13.691) You aren't getting there, because you're not buying the cheap vinyl ones.

Right. Yeah. Master Ranger says, Disney Imagineering has to have woodworkers. A woodworkers tour and camp may be a thing that could be arranged if you all have the contacts. He also says, drawers are the absolute worst. I feel seen after all this. Yeah. There's a lot of...

Phil (12:46.38) ways that people describe a project where they get all wrapped up in the casework of it or some other decorative detail and then you get to the end and it's like now add drawers and doors and depending on what you're doing that's valid but that's also like you're missing a big part of it.

The pragmatic luthier says, I'm a firm believer that if you want to be a better woodworker, of the things you can do to become at one thing you can do is to become at least an entry level machinist. Having at least a hobby milling machine, like we're talking about, and a small lathe in your wood shop expands your ability to make any number of jigs, fixtures, patterns. These machines, along with the peripheral measuring equipment and a small surface plate,

allow you to do very precise work and the skills used to operate them are transferable to your woodworking. Machinery, particularly with respects to measuring and setup. Besides, the answer to the question, how many machines do you need is one more.

Phil (13:57.817) So yeah, one other tool that I had thought about in this is for metalworking is a little narrow belt sander.

Logan Wittmer (14:08.248) Yes, and actually I saw it, I forgot that the one we built on the TV show, that you have that in your shop. is, mean yeah, like that, anything that can remove material quickly from metal is well worth the space in my opinion. Cause trying to hand file it, no way, nope.

Phil (14:35.756) Yeah, because I have a decent set of files and I'm okay with it, but it's really easy for that to turn into a super long process or you can kind of dork up a piece in a way that you don't really want to. yeah, having a, yeah, some kind of a way to remove metal quickly or to refine a a cut metal surface is critical.

Phil (15:03.894) I I think you could do double duty with a narrow belt sander that you could use that on small wood pieces as well. Yeah. And finally, last but not least, Harold McDonald says, now that the harvest is over, I'm ready to return to my sauna sessions and my heckling duties. Prepare yourself.

Logan Wittmer (15:24.402) Yes, thank God. I was wondering. Well now, but now, yeah, now I feel like all of our like long session podcasts have been in vain because we always say perfectly timed for a sauna session. Harold's been in the field. He hasn't been in the sauna.

Phil (15:28.332) Yeah. Welcome back, Harold.

Phil (15:53.177) Right. He's ready to go. As always, we want to hear your questions, comments and smart remarks. You can email them to us. woodsmith at woodsmith.com. Just put the podcast in the title of your message and then it'll get to me. Or you can leave it as a comment on our YouTube channel for the shop notes podcast. Check it out youtube.com slash shop notes podcast.

We welcome any and all feedback and we'll read it on the air.

Logan Wittmer (16:27.247) You're warned.

Phil (16:29.026) Yeah. Speaking of YouTube, just this past week launched the second installment of my shop tour. Several people who have been listening, listening to the podcast have brought that up. That one dropped just, just a few days ago from the time that we were recording this episode. So I'll put a link to it in the show notes page. You can check that out. We're looking at what I would call like the middle section of my workshop.

where all of my machines are. So thanks to everybody who's listened, watched that already in the comments that you have on there. Really appreciate that. So.

Next segment that I want to talk about is to kind of review some of our travels as we're winding down the summer travel season.

Phil (17:24.982) Logan, you were at the Texas Woodworking Festival.

Logan Wittmer (17:29.315) was yeah we did a one of our ad directors and myself did a trip quick to central Ohio just to visit a couple people and then we jumped on a plane and headed down to Austin Texas and if anybody knows me Texas is my favorite state in the Union not a huge fan of Texas for no reason in particular other than it's just a hot dry state

in the places I've been. know it can be sticky and humid in others. But yeah, the Texas Woodworking Festival was very cool. I've never been. That is put on by a gentleman who is a contributing writer of Popwood, Austin. And it happens to also be in Austin. So it was very cool to see. Definitely much more hour speed than something like IWF or AWFS.

has a lot more of our audience there. I've talked to a lot of people, a lot of people stopped by our booth that we have because we did have an active interest media booth myself and Amanda from Fine Woodworking and I believe Will is the new editor of Fine, or one of the editors of Fine Woodworking. He was there as well. So I got to meet him. That was pretty cool. And we got to see a lot of people. It was definitely, as I said, much more aligned with

our audience. a lot of the stuff that's there are companies that most of us are familiar with. You know, it's not the big CNC automated type of stuff. This is more of like, you know, shapers there. Felder was there. Mullet tools. I mean, there was, there was a bunch of them, a bunch of people that you would walk into Rockler or would craft and you'd find their products. So,

Lee Nielsen had a booth, Bad Axe Toolworks had a booth. Yeah, lots of them around, so it was pretty cool. Some I haven't heard of before. There was some epoxy companies. There was one based in Texas that was there. Our guys from Walters Oil, who are sponsoring Woodworking in America, were there. So yeah, was a good trip. It was a fast trip, which...

Logan Wittmer (19:53.476) is how any trip to Texas should be. I'm rage poking all the Texans right now. I think Alex and I landed in Texas at like 6 p.m. local time and we were back on the plane at 3 p.m. the next day. So it was a fast turn to burn, which was, know, honestly, just for like popping in saying hi to

Logan Wittmer (20:22.323) the vendors we wanted to say hi to was perfect. You know, it would have been cool to like hang out and talk to people because I talked to lot of people that unfortunately listen to this podcast and they've seen our TV show and stuff like that. And I would have loved to hang out for the weekend and tongue in cheek. Downtown Austin is actually pretty cool, so it would have been kind of fun to hang out there.

I saw some of the Waymo driverless taxis, which is very odd. And it's also very odd when somebody's sitting in there trying to get out of the, at the hotel, but the taxi doesn't think it's there yet. has to move another four inches ahead and it won't open the doors until it's landed in the spot. So yeah, there was like.

Logan Wittmer (21:16.726) Yeah, there's like three ladies in this Waymo trying to get out of the Waymo at the hotel, but it didn't think it was there yet. It was waiting for a car in front of it to move. it literally like they rolled down the windows like we can't like the doors won't unlock. We can't get out. And then the car pulled away. The Waymo moved three inches and then parked and unlocked the doors. I'm like, that's annoying. That's annoying. But yeah.

Phil (21:46.435) Yeah, it is a little disconcerting to see those for the first time, especially when there's nobody in it, like no writers either. That, cause when we were there in June, I saw that. And then to see, you know, a few of them kind of moving together. That was, yeah.

Logan Wittmer (21:59.939) Yeah, yeah, like they're in packs. I talked to the Uber driver on the way to the airport. And I was like, what do think about these these way modes? And he's like, oh, man, he's like, they do stupid stuff. I was like, what do you mean? He's like, look at this. And there was one that was like trying to turn in front of traffic, but it was like half turned and it was waiting for everything to pass, but nothing could pass because it was half in their lane. So just not there yet. no, it was cool. If you are in Texas, or if you are in a surrounding state of Texas, I think that that is a worthwhile show to go to and walk around.

Phil (22:48.28) All right, while you were in Texas, I was in England with our first ever woodworking tour, along with Mike Peckovich from Fine Woodworking. And it was not nearly as hot in England as it was in Texas. No, it was, we had transitioned to sweater weather already over there. So that was, that was delightful, frankly. Spent a couple of days in London.

Phil (23:17.326) seeing a few sites and then a few days in the Cotswold region seeing a few other woodworking sites and it was it was a blast hanging out with 24 other people on the tour riding around in a tour bus. I think that was one of the sneaky benefits of being part of a tour is

I kind of hate driving to a new place because I want to see everything, but then I also need to kind of keep my eyes on the road too and not die.

Logan Wittmer (23:48.61) Yeah, overrated. If you had Waymo.

Phil (23:50.637) Yeah. Right. Yeah. That could have worked as well. But that was a lot of fun. It was, I know we kind of talk about it a lot, but there is something to be said for seeing furniture in real life rather than just simply by photos. Because with a photo,

whatever is important to the photographer is what you're going to see and that might not be the same as what's important to you.

Phil (24:33.836) We were part of the Cotswolds is the like the Cotswolds school of architecture and furniture building like the Gimmsons and Barnsley's and whatever. And they have a very distinct furniture style. And one detail that I have never seen explained and didn't really know existed was that a lot of the case pieces, not just by the Barnsley's, but by another guy.

Phil (25:03.106) Gordon Russell was the case pieces were joined with finger joints.

and then like every fourth joint, but that could be variable, was a dovetail.

Phil (25:21.43) So it was like this finger joint dovetail motif that, and again, it was on pieces that I've seen in books all over and just, it's never brought up.

Phil (25:37.955) Yeah. I also want to know how, because they were, the dovetails were spaced in the same kind of increment as the finger joints. And sometimes the dovetails were the same size as the finger joint. And then sometimes it was kind of like a houndstooth where the dovetail was much bigger than the finger joint was. Yeah.

Phil (26:19.544) Here's something else. In the age of the smartphone, it's really easy to go to a, you know, like a historic house or museum or something like that and see cool stuff. And then you just take a bajillion photos of it, of the things. Which I think there's some value to, but one of the places that we were really excited about seeing as we were walking in the door, they're like, BTW, can't take photos, can't touch any of pieces.

Phil (27:09.71) How do you, yeah, how do you take in what you see, that you came to see? it was basically like the English arts and crafts version of the gamble house. Architect designed the same place and then his or a very related firm, the Gimsons and Barnsley's did all the furniture on the inside. So really wanted to see this place, but now you can't take photos of it. So what do you do?

Phil (27:42.816) appreciate it. Because there's so much there. It's not like you can just do like the thing that you tell your kids to do like take a picture with your eyes.

Logan Wittmer (28:02.069) Well, yeah, I don't know. See, that's not one of those things that I would have thought about. I mean, I've been to several museums and stuff like that. And most of the time, yeah, you can take pictures. Sometimes it's no flash photography, which is pretty common. And that's fine. That is what it is. But I would have fully expected that you would have been able to take photos.

Phil (28:29.762) Yeah. Yeah. So I had a notebook with me and I sketched out a few details that I wanted to see and think about stuff that stood out to me. You can't use a sketchbook in the same way that you can use your smartphone to just blast away at everything. But then maybe it makes you focus on some of the details a little bit more or looking at them in a little more of a holistic way. It definitely helped being there with another group of woodworkers where you could talk through a piece, you know, where it was like an examination. You just walk up to this piece and it's like, what are you seeing? And you know, if you or I were to do that, you would see stuff that I wouldn't see first go around and vice versa.

Phil (29:26.604) And that could lead to some really cool conversations about, you know, what's going on in a piece of furniture.

Phil (29:41.706) Also interesting to me what the British do with the Chamfer. They love their Chamfers.

Logan Wittmer (29:49.001) I do too.

Phil (29:50.463) not just in the Cotswolds furniture, but we were at several places, you know, through the Victoria and Albert Museum in London, all across time of British furniture is this very deliberate and artistic use of chamfers that I think is kind of amazing when you consider how bland a chamfer can be sometimes.

Phil (30:23.896) just really cool different angles, the way one chamfer blends one surface into another. How do you terminate chamfers? All of that.

Phil (30:38.392) Lots of fun stuff. Then I thought of you while I was there, Logan. We had a guy who did a demo on boxwood wind instruments. He's a professional oboe player, specifically Baroque style oboes. And then he nerded out so much that he makes his own out of boxwood, English boxwood.

These were a delight to see and to, and to, he passed around a couple of them and that just, you know this, when you turn boxwood well, it takes on this like satiny surface that.

Logan Wittmer (31:33.724) Yeah, it's almost like plastic in the best way.Were they three-piece oboes for the most part? Yeah.

Phil (31:48.749) Yeah, he actually had several different types because he had made some flutes, not the like side playing flutes, but the he had a couple of very, I hate to say primitive because they were well done, but early styles of flutes. He had, he actually did have a recorder too, because apparently that's a real instrument, not just a fourth grade music class instrument. And then several styles of oboe.

Logan Wittmer (32:04.166) Almost like a recorder.

Phil (32:18.146) that he made, all with different sounds. then so he talked about how he's got connected to a guy who we were supposed to meet originally and do a tour of the boxwood plantation. But the guy Hugh Crompton had recently had surgery, so he was unable to attend. We had a thunderstorm that day, so just made it a little problematic to be tromping through the woods, even though that would have been cool. But this guy

Phil (32:48.168) Joel, I'll put a link to him on the show notes page, was super nerdy about Boxwood in a way that was contagious and enthusiastic.

Phil (33:03.362) And I know that not long ago, you had acquired some boxwood from an auction.

Logan Wittmer (33:14.553) I have like 40 boxwood logs laying in the shop. I don't think I'm supposed to import it, but I did.

Phil (33:24.844) All right. But it's a really cool material. It was. Yeah. Did you do one of your miter planes in boxwood? Okay.

Logan Wittmer (33:28.902) God, it's so great. Yeah.

Uh-uh. No, No, I have a build... Both my build card or planes are boxwood. No, I did the miner planes in pear and apple. Yeah, no, the boxwood is just... It's unbelievable. Like, it turns so nice. I've done... This is one of my favorite things I've ever turned.

Logan Wittmer (34:01.455) It's this little threaded Box, that's all it is. A little threaded boxwood box with a grain match on the seam. It just, it turns so nice. It's so dense. It takes forever to grow. Now, to be very clear, I have never had good boxwood. The boxwood that I have gotten a hold of are in log form and when logs dry, they crack. So it's very hard to get a...big piece out of what might be a four and a half inch diameter log at most, you might get like, you're gonna be hard pressed to get a two by two square out of it. So like what Hugh has, mean, he's purposefully sawing these boxwood into blanks. So he's actually able to get good material out of them. Where a lot what I have is it's like,

A tree surgeon in the UK was taking down a boxwood hedge and somebody threw it in their trunk and carried it away and that's what I have.

So yeah, it's a little different. But yeah, it is a wonderful, wonderful material.

Phil (35:27.022) So yeah, it was really cool to see that. And then we had a turning demo by a guy named Paul Hannaby, and he had a little threaded boxwood container as well. And I've done some stuff with making threads in wood in maple and got it where it's like, yeah, this feels really good. But threads in boxwood, they're like really nice.

Phil (36:12.974) So that part was really cool. then speaking of turning, because I've watched you do several turning demos, you know what this is like just from any kind of teaching, is he did a two hour demo on making a goblet that had like a twist in the stem.

And it's one thing to be able to turn a goblet in two hours and add a twist in the stem. It's another thing to do that before a live studio audience. And it's a whole separate thing if you're also going to take questions. Because that's not two hours. That's something that this dude has practiced and done multiple times to be able to have that confidence and competence to be able to do it well and be engaging about it.

Although I think his pro level move was renting out a pub in the town that we were in. So he was like in the social hall part of the pub where he did his turning demo so that when we came in, a bunch of Americans and a coach, when the people on the tour realized that we were in a pub, they're like, I'll go into the bar and grab like a pint and come back and sit down and enjoy a beverage of their choice while watching a turning demo.

And that was really cool. And I realized he was doing a goblet, but you know, there's end grain hollowing on there. And I sent a picture to you because he had this little wee little Vickmark lathe that just worked a treat on that.

Logan Wittmer (38:10.811) Yep. there was one of those. So Vickermark makes a VM 100, they make 240 and then they make a 300. And the 100 is the little, the little bitty guy. And there was one recently, like within the last year for sale. And I feel like it was like a two hour drive to get it. And it was like the guy had stripped it, repainted it. It didn't have a motor, but

The guy was asking Harley anything for it and I kind of am kicking myself for not getting it because they're just a nicely made little

Phil (38:49.326) Yeah, and he had it on a folding base and it just was a smooth running quiet machine just did a really great job.

Phil (39:03.022) So yeah, one woodworking tour in the bag. I think it was a huge success. And I mean, I know you, me and Mike are on the committee for what's going to happen next year. So I would say chances are high that there's going to be for sure one next year. And then we're just got to sort out destinations and whatever to go with it.

Logan Wittmer (44:52.529) Yeah. So like talking next year about potential trips, we are strongly considering one of them being to Japan. So I'll be interested to hear from people on what their opinions are on that. Because when, when Phil and Mike and I were talking about this trip and what potential next trips are, I, I'm,

I'm conflicted because Japan to us in the States is a pretty exotic country. You don't speak the language, probably. And it's one of those things that I can see it going either way on whether people would be really interested in going as a group or if somebody's more interested in going to, let's say, England, where everybody speaks English, like you can just go.

In the free time, you can go screw around on your own. Or if there's more interest to going somewhere like Japan, where it's like, you you are with a group. So it's not just you not speaking the language. It's 30 other people. you guys, you know, there will be a guide. There will be all that stuff and a translator and stuff. But I'm interested to hear what people's feedback is on it. You know, to me, it seems like it's one of those places that has a really rich woodworking history and a very long woodworking history. So I think there's a lot to see. And I've started working on an itinerary for there, and there's a lot of stuff to do.

Phil (46:34.38) Okay. Yeah, I think so. And for the fact of, you know, for most folks,you know, there's a lot of cross-cultural pollination, but culturally, Japan is very different from the way we live here. And I think that has a lot of value in terms of being able to see that too.

Logan Wittmer (46:57.638) Well, and I feel like that those cultural differences, the way they approach everyday life, having visited there, I think translates and is reflected on and in their woodworking and in their style of woodworking and how they work. And I think there's some value that a lot of people could take from that. So it's pretty interesting to me.

Phil (47:51.343) All right, final segment of today's show has to do with a series of photos that Logan sent out on one of our group chats here at work. We use Microsoft Teams for better or for worse for a messaging program. And Logan, you sent out what can only be described as a cry for help last night.

Logan Wittmer (48:16.45) So that's what I was trying to clarify with you. Because I sent pictures of something that was for sale in the local Des Moines area. Nope, a 30 minute drive from the trailer rental place. How do I know that? Because I went and did that this morning. And I said I was gonna go pick it up and Phil's first thing was congratulations. And I said, Phil, I don't know if this was a congratulations or a cry for help, like a cry for an intervention.

What I bought was not a machine. It is from the Handy Manufacturing Company. And it was on Facebook Marketplace described as a furniture clamp.

Or a furniture press. They called it a furniture press. And when I saw the photos, I'm like, that looks like the biggest ass veneer press I have ever seen.

And then it's not of an ear press. So I Googled, by Google I mean go to my second favorite website in the world, vintagemachinery.org, and I pull up the manufacturer page for the handy manufacturing company out of Chicago, Illinois. And sure enough, their catalog from 1937 shows this thing as a furniture press.

Logan Wittmer (50:06.811) The best way to describe this thing is an eight foot long cast iron veneer press with a 35 inch hand wheel to move one of the four foot by three foot plattons in and out. So this thing is meant so you could put an entire furniture case inside of it, spin the wheel and it clamps the entire thing end to end. like instead of like, yep, squeeze. Like so instead of like eight clamps, You just need this big one that's 2,000 pounds. For my mansplaining this. I'm practicing this for when I get inside to explain this to my wife in a little bit.

You do not see these things often in Iowa. Iowa does not have a history of furniture manufacturers or woodworking studios. What we have are corn and soybeans and pigs and chickens.

Phil (51:19.214) Yeah. Historically, some of the river towns like Dubuque used to be like the top manufacturer of millwork.

Logan Wittmer (51:30.363) Yes, Burlington, Iowa, I believe was the lumber capital of the United States for a long time because logs would float down the river. But that's the other side of the state. That's like a different country. Okay.

Phil (51:45.078) And it's also totally different woodworking, because it's just long sticks.

Logan Wittmer (51:59.782) The lady was asking a hundred bucks for this thing.

And I'm like, you know what? I just spent $100 on coffee for the shop here yesterday. Like this is way cooler than that and Nate can't drink at all. like, I'm like for a hundred bucks, I have this, like there is $400 in scrap in this thing if it's busted, right? Because the, the, and

Logan Wittmer (52:33.766) Phil has the page I sent him out of the thing. It says approximate weight is 2150 pounds. So this thing weighs a ton. That's like 350 bucks in scrap.

Phil (52:53.718) Yeah, because it's old enough where the industrial design on it, like the castings on the hand wheel and on the platens themselves, it's just pretty.

Logan Wittmer (53:07.063) It is very cool. Yeah. One of our other guys, Ben, messaged me something this morning and I said, well, I'm going be out this morning. I'm picking something absolutely unnecessary up. And I sent him the pictures and he's like, hold on that catalog page. The very first line says this is an absolutely necessary item to have. And it does like, dang it. So like.

Logan Wittmer (53:34.841) There are the only thing wrong with this thing. Everything moves on it and it rotates. yeah, and it rotates. like the entire thing, instead of standing like where you put like a case in legs down, you can clamp it, but then you can flip the entire thing upside down to work on the bottom or work on the top. So it was like one of those things like you had a craftsman in a furniture company, let's say in Grand Rapids, Michigan building desks.

Logan Wittmer (54:04.975) they clamped it up and they had to start working on the feet, they would just squeeze the wheel, pull the lever and swing the whole thing up and lock it in place. And then they all of a have the feet facing them, which to me is like the coolest thing in the world. The hub that rides on the shaft that that locking lever goes into is broken half. Half of it's missing, which is fine.

Logan Wittmer (54:32.129) I have a vertical mill and I have a metal lathe. I can make a new one. So there's that and it is missing two of the four cast iron wheels on it. I can replace those easily though. So...

Phil (54:35.19) Hahaha

Phil (54:46.254) Yeah.

Logan Wittmer (54:48.645) It's still a lot of rust and painting, but it's a pretty, like, I found a guy today, he messaged me a price, 250 bucks to sandblast the whole thing.

Phil (55:00.758) yeah, that's not bad.

Logan Wittmer (55:03.14) Like, come on, what am I going to do with this when it's done? I don't know. I had no idea. But it's cool. And it's one of those things, like the guy and the lady I got this from, had, they were up by Huxley, so Ames, about 40 minutes north of Des Moines. And they had, he had a sawmill, had a Wood-Mizer LT40 sitting there, bunch of buildings, bunch of big machinery.

He's like, I don't know what this thing is. My brother got it from Missouri. We've been calling it a furniture press. I'm like, that's 100 % what it is. They had a bunch of other rusty stuff that I tried. I walked by like this, like as I was walking towards this thing, because I didn't want to be tempted. And they just had it sitting outside as like decoration, because it is, it's very cool looking. So they just had it sitting outside as decoration.

Phil (55:44.984) Yeah.

Logan Wittmer (56:00.548) I couldn't let it just sit there.

Logan Wittmer (56:05.709) So I was afraid that my skid loader would not pick it up.

Phil (56:12.19) really?

Logan Wittmer (56:13.06) because we put it into the poor little U-Haul trailer. U-Haul, if you're listening, I did not put this in your U-Haul trailer. And she went low.

Logan Wittmer (56:28.26) The U-Haul trailer said it had a 1600 pound capacity. I have to assume that they buffer that because they know people are gonna overload it. So I just was taking into account the overloading weight. But yeah, it's super cool. If I can put some wheels on it, the problem is the wheels are fixed. So they're all for fixed in the same direction.

Phil (56:38.412) overload it. Yeah.

Phil (56:44.034) right

Phil (56:58.878) so it's not like it.

Logan Wittmer (56:59.555) So it's like, how do you spin it?

I don't know. But if I get it where I can roll it in and out of the shop, it would just be cool to just use it. You know, I don't know. Or what I thought was really cool and what makes this interesting. And it's not just a squeezer. mean, it is a squeezer, but handy when they manufactured this. So the patent date on it is March of 1920. When they made this thing, the platens are

Phil (57:10.416) yeah. Yeah.

Logan Wittmer (57:33.603) pre-drilled with a bunch of holes for attaching fixtures to.

Phil (57:38.126) okay.

Logan Wittmer (57:39.812) So I, when I was kind of trying to decide, when I was trying to talk myself out of buying this thing via Googling other people that have them, which there are not many around, which did not help the case, I found a couple that were up for auction from furniture companies that were going out of business and stuff, and they all had fixtures attached to them. So like people were like clamping chair parts or they were doing bent lamination or they were using it for steam bending where they put a male and female mold in and just

Frank that's not out of it. I know so that's where I'm like, okay. I can't let this thing not Come home with me for a hundred bucks. Come

Phil (58:17.068) Right. Yeah.

Phil (58:21.784) Yeah, well, mean, because.

Phil (58:26.562) Right.

Logan Wittmer (58:28.29) I mean it is big. There's no two ways about it. This thing is bigger than a jointer I just got rid of.

Phil (58:37.838) but there's definitely a...

there's definitely a visual appeal to it. And like you said,

Logan Wittmer (58:44.853) yeah.

Phil (58:47.682) You know, it's not just a

It's not just a clamp. Like if you can fixture it up and you were doing it for stuff that you were doing repeats of.

Logan Wittmer (58:54.742) Yeah.

Logan Wittmer (58:58.083) Yeah. maybe that's where, you know, I don't want to be in the production furniture business. That's where the thing really would be awesome. like, I see it like trying to be a realist. I see myself maybe getting this thing fixed up, painted, use it a couple of times, and then sell it in some way that would actually do production furniture where they're like, you know, I'm making 30 chairs at a time or something like that.

Phil (59:06.093) No.

Logan Wittmer (59:27.447) That's what I... I guess there's just a need in me to save some of this stuff. Where it's like, would rather not have this thing just sit outside and rust away. Because it's super cool. Nobody makes those anymore, right? Like, can you go buy something that will clamp together an entire workbench base at once? I don't think so.

Phil (59:46.637) No, no, because a lot of times when you see those, they're like panel clamps or, you know, like a sash clamp or something like that, but not like a, not a carcass clamp. So, and I, and that's why I didn't really ding you too much on it because I'm very much of that same kind of person where it's like, I would like to think that when I'm old, somebody can still find use for me. And then it's like, you know, there's just because it's old doesn't mean that it's not useful. And

Logan Wittmer (59:53.836) Yep. Yeah.

Logan Wittmer (01:00:09.334) Yeah, yeah.

Phil (01:00:16.374) Yeah, you just there's also a playful element of it. What's like

Logan Wittmer (01:00:20.827) yeah.

Phil (01:00:24.034) Let's be honest, a hundred bucks to some people is a lot, to other people it's not much. For a lot of us in this day and age, we've all spent a hundred dollars dumber.

Logan Wittmer (01:00:35.47) yeah, yeah. So yeah, mean, and that's one of those things where it's it's worth like a hundred bucks is me taking my family to the movies twice.

Phil (01:00:38.22) than this.

Phil (01:00:49.952) you

Logan Wittmer (01:00:51.521) I'm gonna get way more enjoyment out of this thing than taking my family to the movies. no, it's just one of those things that's like, okay, I have a feeling that we paint and picture me being a hoarder. That's, don't think the case, but I also like, I don't know. It's just, I like my rustables. I like that term that John used earlier.

Phil (01:01:15.82) No, think. Yeah.

Logan Wittmer (01:01:20.853) You

Phil (01:01:21.592) Yeah. I like that because I think one of the things that attracts me to woodworking is the spirit of curiosity or experimentation or playfulness. know, like I build a lot of kind of shop made tools or jigs or whatever where those lines kind of blur simply for the fact where it's like, this seems kind of cool.

And if I can do that myself, like now I've learned something about this, about myself, how I want to work with it. Do I necessarily keep all of those things? No, a lot of times I'll give them away to somebody else who can find a use for it or whatever. But I think, yeah, like you definitely not a hoarder because you've gotten stuff in, found some enjoyment out of it or realized like that's just not your deal. And then you just.

Logan Wittmer (01:01:51.966) YEAH!

Logan Wittmer (01:02:16.33) Yep, it's gone.

Phil (01:02:19.338) send it back out into the universe for somebody else to enjoy, probably in much better shape than what you found it in.

Logan Wittmer (01:02:25.259) Hopefully, yeah, hopefully. Yeah. And like, to be very like, to be honest, a portion of my thought last night, as I was looking at this thing was, okay, I don't really need another project. It's not a huge one though. I pay somebody to come out and sandblast it for 250 bucks and all I have to do is spray coat of paint on it, I can spray coat of paint in a day.

But in reality, what I was looking at is those platens are freaking huge in their cast iron. even if, like, I didn't know what type of shape this was in. I didn't know if anything moved. I didn't know if it was missing parts. All I saw was one or two photos of it. What I'm looking at is those plans are huge. They make really cool, like a welding table or something. If it's broke, you know what I mean? There's

big eye beams on it, like the entire construction of this thing is made of like an eight inch square eye beam. I can always find a use for that. And the thread, the acme thread that moves the platen in and out is a two inch diameter acme thread. Like, it's huge. And I'm like, I can find something to do with that. So at that point, I was almost buying it for parts, but it's...

Phil (01:03:40.803) Whoa.

Logan Wittmer (01:03:51.232) cool enough that I'm like I'm not gonna part this thing out, gonna sandblast this MF or paint it. So, and then I have to at least glue one thing up with it before it goes back into the wild. So, right now it is sitting in the healing weeds outside, so hopefully the healing weeds do their business and fix some of the things on it that are missing, which aren't many. So, yeah.

Phil (01:04:14.232) Yep. Yeah. But like you said, like there's no motor that you have to tear apart. There's no big cutter head that you have to replace. know, it's, yeah, this is all pretty simple stuff. So.

Logan Wittmer (01:04:21.332) now.

Logan Wittmer (01:04:24.787) There's no bearings. Yep.

Logan Wittmer (01:04:29.524) Yeah, honestly, the way it sits, I could go throw something in it and squeeze it together if I want to do. Like, it's usable. It is a little...

Phil (01:04:35.947) yeah.

Logan Wittmer (01:04:43.423) Some of this early industrial stuff, you're like, this was before OSHA really cared. Because this thing weighs 2000 pounds. It is eight foot long. I read a nine foot trailer and it barely fit. But width wise, the cross section is only like 18 inches. And it's very, and it's very top heavy. Well, I take that back.

Phil (01:05:06.021) really, it's that narrow?

Logan Wittmer (01:05:10.973) The platens are 36 inches, but the base is maybe 24. So I'm like, there's not a real big base on this thing. It looks like the base needs to be twice as wide as it is. And I think it's meant so it can roll next to other. If you had a fleet of these things that you were gluing up cases at once, all at once, you could get them tight together and stuff. But I'm like, man, I hope my kids don't go play on this thing, because it looks like it could tip over pretty easily.

Phil (01:05:15.824) yeah.

Phil (01:05:44.716) Yeah. Super cool.

All right, so there's a question. What is your weakness when it comes to tools? Vintage tools, hand tools, the unusual and weird wild kind of stuff. Let me know. You can send that to woodsmith at woodsmith.com. Leave it in the comment section on youtube.com slash shop notes podcast. Special thanks to Harvey Woodworking for sponsoring today's episode and we will see you next time everybody. Peace out.