Woodworking can be pretty flexible. There’s usually more than one tool and technique you can use to perform a particular task. But, there are some woodworking operations that can best be accomplished in a particular way. Adding a decorative edge profile to a glued-up panel falls into this category. Routing the profile is the number one option for this task. Assuming the size of the panel allows it, I always rout edge profiles at the router table. The setup is easier and the large surface of the table provides good support for the panel. And although the operation may seem pretty foolproof, there are always a few tips and techniques that can be used to help produce a smooth, crisp, attractive profile.

The router table has to be smooth, flat, and “catch-free.” If the table isn’t flat, you may have trouble routing a consistent, full-depth profile along an entire edge. A table with a very minor “hump” is workable, but it’s difficult to get good results with a concave surface. The center of the panel will ride up as it passes over the bit and you may not be able to press it flat against the table. If you use an insert in the table, it should be perfectly flush with the surrounding surface. This will eliminate the chance of the panel catching, bumping, or dipping as it passes over the edge of the insert, resulting in a “hiccup” in the profile.

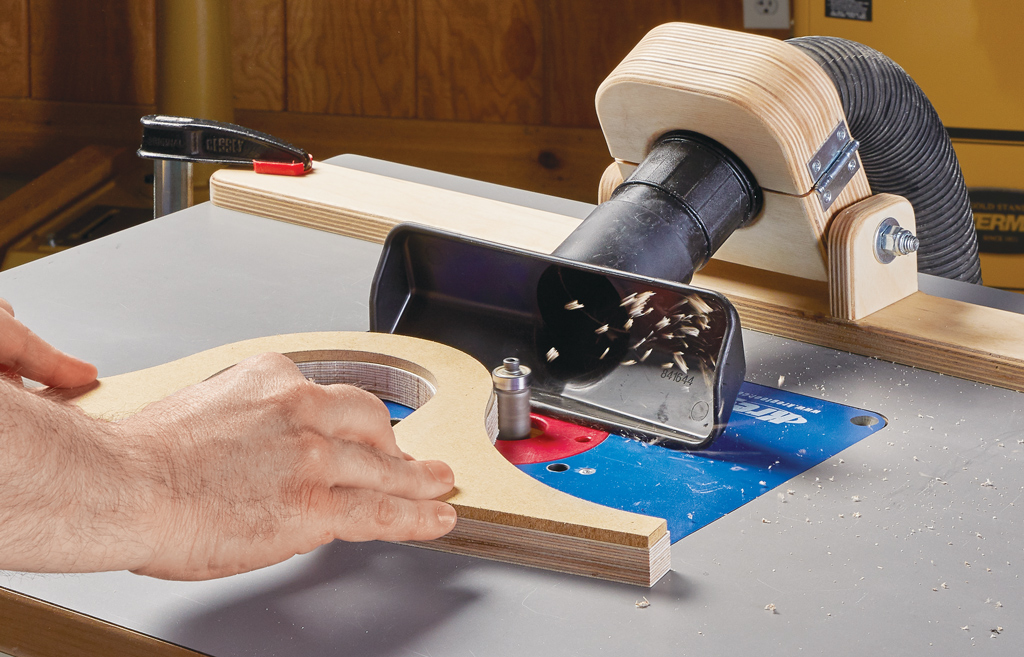

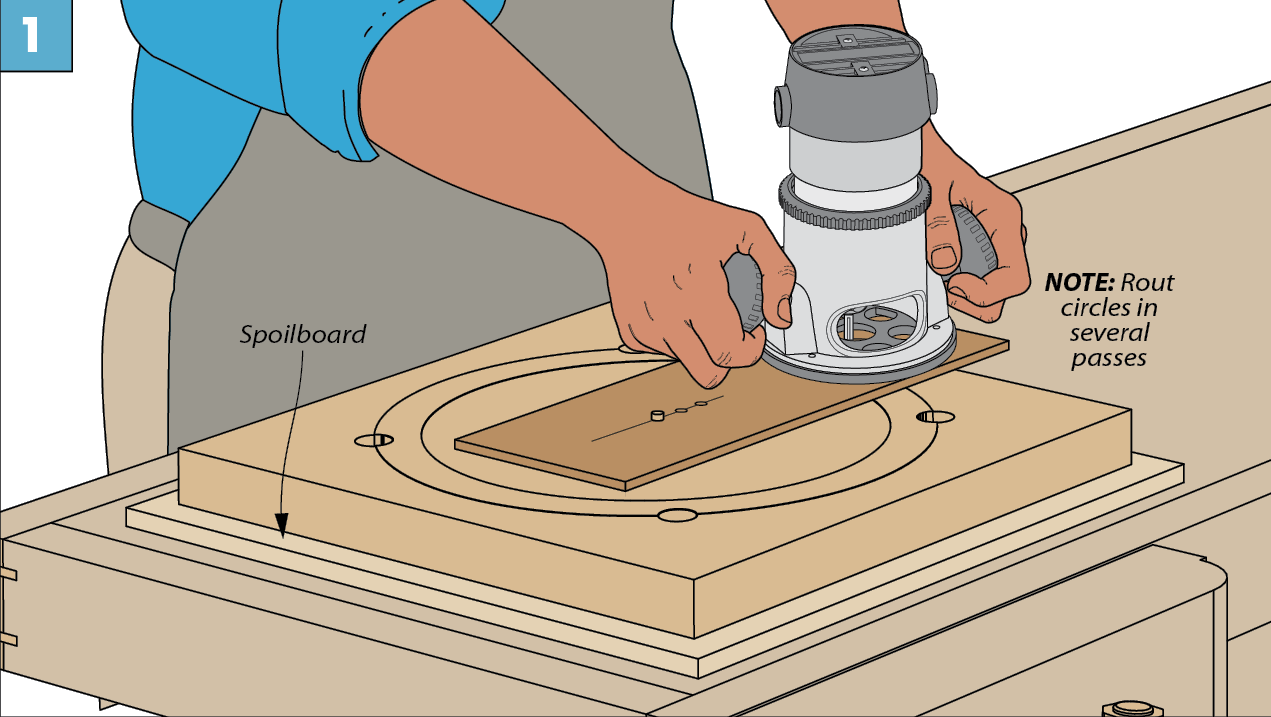

When routing all but the very smallest profiles, it works best to make multiple, light passes. Taking light cuts will minimize chipping, leave a much smoother surface. The depth and number of passes is determined by the size and shape of the profile you’re routing and the type of wood. There are two techniques for taking multiple passes — you can raise the height of the bit between cuts, or move the fence back, exposing more of the bit. I prefer the latter approach. For starters, it’s easier to move the fence than to change the bit height. And once the bit height is set and tested, you’re assured of an accurate depth-of-cut.

When routing across end grain, you’ll always experience some degree of chipout as the bit exits the cut. So if you’re going to rout a profile on all four edges of a panel, always start by routing across one end-grain edge. This way, the following long grain pass will rout away any problems. If you plan to rout a profile on three edges of a panel, plan your first end cut so that you can next rotate the panel counterclockwise to rout the long edge. Follow this with the final end cut. To avoid chipout on the second end, use a backer board.